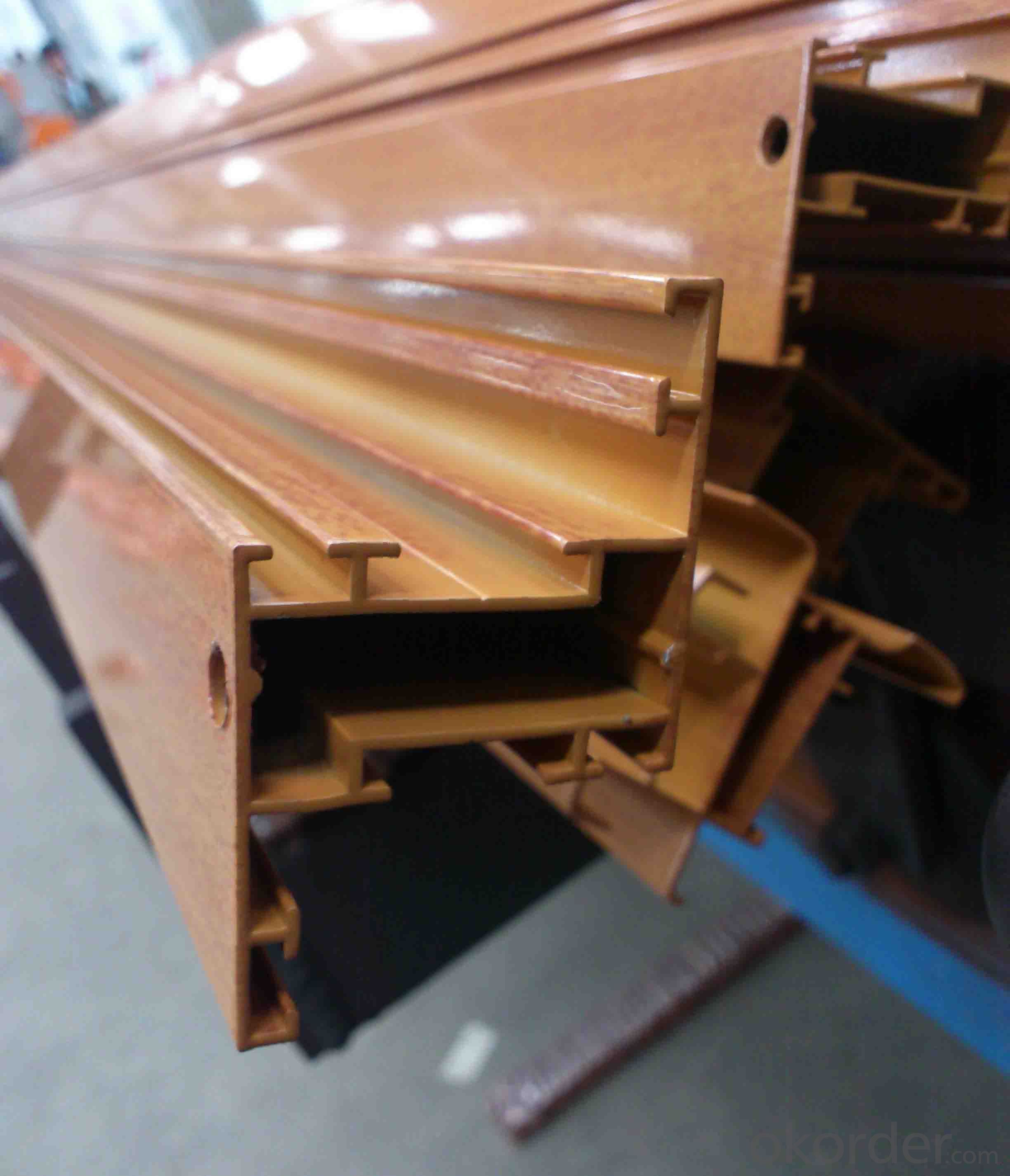

Aluminum Profiles for Africa:Windows & Doors

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

You Might Also Like

Aluminium profile

we have the whole window system for Africa Market

Surface:Wood Color

Material: 6063 T5

- Q: What are the necessary upkeep and care procedures for aluminum profiles post-installation?

- <p>After installation, aluminum profiles generally require minimal maintenance due to their corrosion resistance and durability. However, regular cleaning to remove dust and dirt is recommended to maintain their aesthetic appeal and performance. This can be done using mild detergents and water. Periodic inspection for any signs of damage or wear is also important to ensure the structural integrity of the profiles. In case of any damage, it should be promptly attended to to prevent further deterioration. Despite their low maintenance nature, it's crucial to follow the manufacturer's guidelines for care and upkeep to prolong the life of the aluminum profiles.</p>

- Q: How do you protect aluminum profiles from scratching or damage?

- There are multiple methods available for safeguarding aluminum profiles against scratches or damage. To begin with, a commonly used approach involves applying a protective coating or finish. This can be accomplished by utilizing paints, lacquers, or powder coatings that serve as a barrier between the aluminum surface and external elements. These coatings not only enhance the appearance but also offer protection against scratches, corrosion, and other forms of damage. Another effective temporary solution is the utilization of protective film or tape. These films or tapes can be directly applied onto the aluminum profiles, acting as a shield. Generally transparent, these films can be easily peeled off once the profiles are installed or ready for use. A different technique involves handling and transporting the aluminum profiles with caution. This entails the use of appropriate handling equipment, such as gloves, to avoid direct contact with the surface. Additionally, the use of protective packaging materials like bubble wrap or foam can provide cushioning during transportation, preventing scratches or dents. Regular cleaning and maintenance of the aluminum profiles is also crucial. Dust, dirt, and debris can act as abrasives, causing scratches over time. Cleaning with a soft cloth or sponge and mild detergent on a regular basis can help eliminate these particles and preserve the profile's appearance. Lastly, implementing proper storage practices is of utmost importance. Storing aluminum profiles in a dry and clean environment, away from sharp objects or heavy items, can minimize the risk of scratching or damage. The use of racks or shelves with protective padding can provide an additional layer of protection. By adhering to these measures, aluminum profiles can be effectively safeguarded against scratches or damage, ensuring their durability and preserving their aesthetic appeal.

- Q: Aluminum profile spraying process

- Powder coating construction technology and requirements of the powder electrostatic spraying is the use of the principle of high voltage electrostatic corona electric field. With high-voltage anode in the gun head on the metal guide, is formed by spraying electrode of the workpiece, the formation of a strong electrostatic field between the gun and the workpiece. When the compressed air as carrier gas, powder coating from guide rod for powder barrels by powder pipe to spray gun, the corona discharge guide rod is connected with the high voltage anode is generated, and the negative charge density in the vicinity of the powder, with a negative charge, and entered into the field of electrostatic field strength is very high, in the dual role of static electricity and gas. The powder evenly ground to powder layer formed on the surface of workpiece thickness uniformity, and heat curing into durable coating coating construction process:

- Q: This question asks for an overview of the various types of fasteners that can be used in conjunction with aluminum profiles.

- <p>Aluminum profiles are commonly used in construction and manufacturing, and they require fasteners for assembly. The different types of fasteners include: 1. T-nuts and T-bolts: These are used for creating strong connections within the profile. 2. Clamping blocks: These are used to secure profiles together without the need for drilling. 3. Corner brackets: These are used to create 90-degree connections between profiles. 4. Angle brackets: Similar to corner brackets but for creating angled connections. 5. End caps: These are used to cover the ends of profiles for a finished look. 6. Dowels: These are used for aligning and joining profiles together. 7. Screws and bolts: These are used for securing components to the profiles. Each type of fastener serves a specific purpose and is chosen based on the particular application and design requirements.</p>

- Q: Are aluminum profiles suitable for use in automotive body structures?

- Yes, aluminum profiles are suitable for use in automotive body structures. Aluminum is lightweight, strong, and corrosion-resistant, making it an ideal material for constructing car bodies. Its high specific strength allows for increased fuel efficiency and better performance. Additionally, aluminum profiles can be easily shaped and formed to meet the specific design requirements of modern vehicles.

- Q: Is it possible to use aluminum profiles for outdoor applications like fences and railings?

- <p>Yes, aluminum profiles are commonly used for outdoor applications such as fences and railings. They are favored for their resistance to corrosion, lightweight properties, and durability. Aluminum can withstand harsh weather conditions without rusting, making it an ideal material for outdoor use. Additionally, it is low maintenance, as it does not require painting or frequent repairs. The profiles can be powder-coated or anodized for enhanced protection and aesthetic appeal.</p>

- Q: Can aluminum profiles be used for electrical bus ducts?

- Indeed, electrical bus ducts can be constructed using aluminum profiles. Within the electrical industry, aluminum is widely employed as it possesses exceptional conductivity and lightweight characteristics. Its remarkable electrical conductivity plays a vital role in efficiently transmitting electrical power. Furthermore, aluminum profiles exhibit durability, resistance to corrosion, and the ability to endure high temperatures, rendering them suitable for diverse industrial applications. Nonetheless, it is crucial to carefully assess the project's unique requirements and regulations in order to ascertain that the aluminum profiles conform to the essential electrical and safety standards.

- Q: Can aluminum profiles be used for creating display systems?

- Yes, aluminum profiles can be used for creating display systems. Aluminum is a versatile and lightweight material that is widely used in various industries, including the display and signage industry. Aluminum profiles offer several advantages for creating display systems. Firstly, aluminum is highly durable and corrosion-resistant, making it suitable for both indoor and outdoor display applications. It can withstand various environmental conditions, ensuring the longevity of the display system. Secondly, aluminum profiles are easily customizable. They can be extruded into various shapes and sizes, allowing for flexibility in design. This makes it possible to create unique and eye-catching display systems that meet specific requirements. Additionally, aluminum profiles are easy to assemble and disassemble, which is beneficial for display systems that require frequent changes or transportability. They often come with a simple slot and groove system or other connecting mechanisms, making installation and maintenance hassle-free. Moreover, aluminum profiles can be anodized or powder-coated to provide a decorative or protective finish. This allows for customization in terms of color and texture, enhancing the aesthetics of the display system. Lastly, aluminum profiles provide structural stability while remaining lightweight. This makes them suitable for large-scale displays or installations where weight is a concern. In summary, aluminum profiles are an excellent choice for creating display systems due to their durability, customizability, ease of assembly, and aesthetic appeal.

- Q: What are the different types of protective coatings for aluminum profiles?

- There are several different types of protective coatings available for aluminum profiles. These coatings are designed to enhance the durability and longevity of the aluminum, while also providing aesthetic appeal. Some of the common types of protective coatings for aluminum profiles include: 1. Anodizing: Anodizing is one of the most popular and widely used protective coatings for aluminum. It involves an electrochemical process that creates a thin, transparent layer of aluminum oxide on the surface of the metal. This layer provides excellent corrosion resistance and can be further enhanced with various dye colors. 2. Powder Coating: Powder coating is a dry finishing process that involves applying a free-flowing, electrostatically charged powder onto the aluminum surface. The powder is then cured under heat, creating a durable and protective coating. Powder coating offers excellent resistance to impact, chemicals, and corrosion, and it provides a uniform and attractive finish. 3. Paint Coating: Paint coatings are commonly used for aluminum profiles, especially in applications where aesthetics is important. These coatings can be applied using various methods such as spraying, brushing, or dipping. Paint coatings provide protection against corrosion, UV rays, and other environmental factors, while also offering a wide range of color options. 4. E-Coating: E-coating, also known as electrocoating or electrophoretic deposition, is an immersion-based coating process. It involves submerging the aluminum profiles in a tank filled with a water-based paint solution and applying an electric current. This causes the paint particles to migrate and deposit onto the aluminum surface, resulting in a uniform and protective coating. E-coating provides excellent corrosion resistance and is often used as a primer before applying other coatings. 5. Clear Coating: Clear coatings are transparent protective layers that are often used to preserve the natural appearance of aluminum profiles while providing protection against corrosion and other environmental factors. These coatings can be applied as clear lacquers or clear anodizing, depending on the desired level of protection. It is important to consider the specific requirements of your aluminum profiles and the intended application when choosing a protective coating. Factors such as durability, corrosion resistance, aesthetics, and cost should be taken into account to ensure the best choice for your specific needs.

- Q: Can aluminum profiles be used in the production of automotive interiors?

- Yes, aluminum profiles can be used in the production of automotive interiors. Aluminum profiles offer lightweight, durable, and corrosion-resistant properties, making them suitable for various interior components such as door panels, dashboard trims, seat frames, and console accents. Additionally, aluminum profiles can be easily customized and integrated with other materials, allowing for innovative designs and improved functionality in automotive interiors.

Send your message to us

Aluminum Profiles for Africa:Windows & Doors

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

Similar products

Hot products

Hot Searches

Related keywords