China Anodized Aluminum Frame Profiles for Alu Profile Extrusion Sliding Window

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Aluminium is a relatively soft, durable, lightweight, ductileand malleablemetalwith appearance ranging from silvery to dull gray, depending on the surfaceroughness. It is nonmagnetic and does not easily ignite. A fresh film ofaluminium serves as a good reflector (approximately 92%) of visible lightand an excellent reflector (as much as 98%) of medium and far infraredradiation. The yield strength of pure aluminium is 7–11 MPa,while aluminium alloys have yield strengths ranging from200 MPa to 600 MPa. Aluminium has about one-third the densityand stiffness of steel. It is easily machined,cast, drawn and extruded.

Aluminium alloys (or aluminum alloys; see spellingdifferences) are alloysin which aluminium(Al) is the predominant metal. The typical alloying elements are copper, magnesium,manganese,silicon,tin and zinc. There are twoprincipal classifications, namely casting alloys and wrought alloys, both of which are furthersubdivided into the categories heat-treatableand non-heat-treatable. About 85% of aluminium is used for wrought products,for example rolled plate, foils and extrusions.Cast aluminium alloys yield cost-effective products due to the low meltingpoint, although they generally have lower tensile strengthsthan wrought alloys. The most important cast aluminium alloy system is Al–Si,where the high levels of silicon (4.0–13%) contribute to give good castingcharacteristics. Aluminium alloys are widely used in engineering structures andcomponents where light weight or corrosion resistance is required

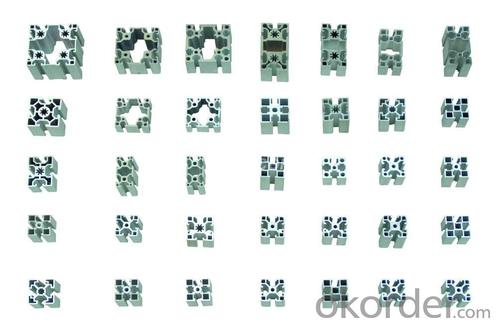

Features:

Material | Alloy 6063,6061,6005or according to customer’s choice |

Temper | T3, T4, T5, T6 |

Surface | Anodize, electrophoresis, powder coating, PVDF coating, wood grain painting, matted, etc. |

Length | Coating 6.5 meters, Anodizing 6.5 meters, Mill finish 5 meters |

Application | Industrial, electrical equipment(TV set, air conditioner, refrigerator, computer), decoration,construction, transportation |

Custom Made | We can package following with customer's request. |

FAQ:

1. What is the form of payment?

Normally 30% TT, L/C at sight

2. Type of quotation?

FOB, CFR, CIF

3. Port of loading?

Shenzhen/Guangzhou port

4. Delivery time?

15-20 days after client’s deposit

- Q: Aluminum profile connecting piece

- Very little to buy this alone, and only with industrial aluminum suppliers. - selling on Taobao is also a way if the price is appropriate.

- Q: How much is the aluminium frame Aonaike surface over three thickness? And three prism specifications?

- The thickness of the aluminum profile is 1.8mm, and the size of the three prism is 136126100,80.

- Q: What is the difference between 6061-T6 and 6063-T6 in aluminum profile?

- Alloy composition is different, 6061 of the other alloy composition is much higher than 6063.

- Q: Can aluminum profiles be used in food-grade applications?

- Yes, aluminum profiles can be used in food-grade applications. Aluminum is a safe and non-toxic material that is resistant to corrosion and can withstand high temperatures. It is commonly used in food processing and packaging industries for various applications such as food storage, transportation, and equipment manufacturing. Additionally, aluminum profiles can be easily cleaned and maintained, making them suitable for maintaining hygiene standards in food-grade environments.

- Q: Can aluminum profiles be used for electrical busbars?

- Yes, aluminum profiles can be used for electrical busbars. Aluminum offers excellent electrical conductivity, and its lightweight nature makes it a cost-effective choice for busbar applications. Additionally, aluminum profiles can be easily shaped and customized to meet specific requirements, making them suitable for various electrical systems.

- Q: Inquire about the various uses of aluminum profiles within the field of architecture.

- <p>Aluminum profiles have a wide range of applications in architecture due to their strength, durability, and lightweight properties. They are commonly used in curtain walls, which are the exterior coverings of buildings, providing both aesthetic appeal and structural integrity. Aluminum profiles are also utilized in window and door frames for their resistance to corrosion and ability to withstand various weather conditions. They are employed in structural glazing to hold glass in place securely. Furthermore, aluminum profiles are used in sun shading systems to control the amount of sunlight entering a building, enhancing energy efficiency. They are also found in handrails, balustrades, and other safety features for their strength and low maintenance requirements. Overall, aluminum profiles contribute to the sustainability and modern design of architectural projects.</p>

- Q: What are the bending radii for different aluminum profiles?

- The bending radii for different aluminum profiles can vary depending on the specific shape and thickness of the profile. However, in general, aluminum profiles can be bent to a minimum radius that is typically around 1.5 to 2 times the thickness of the material. For example, if you have an aluminum profile with a thickness of 1mm, the minimum bending radius would be around 1.5 to 2mm. Similarly, if the profile has a thickness of 3mm, the minimum bending radius would be around 4.5 to 6mm. It is important to note that these are approximate values and may vary depending on the specific alloy and temper of the aluminum. Additionally, the bending process itself, including the method and equipment used, can also impact the achievable bending radii. To ensure accurate bending, it is recommended to consult the manufacturer or a professional fabricator who can provide specific guidelines and recommendations for bending radii based on the particular aluminum profile you are working with.

- Q: Can aluminum profiles be used for transportation applications?

- Yes, aluminum profiles can be used for transportation applications. Aluminum is a lightweight and durable material that offers high strength-to-weight ratio, corrosion resistance, and versatility. These qualities make it suitable for various transportation applications such as aircraft, automobiles, trains, ships, and even bicycles. Aluminum profiles are commonly used in the construction of vehicle bodies, frames, panels, and other structural components, helping to reduce weight and enhance fuel efficiency.

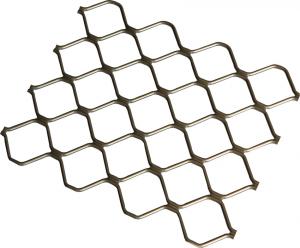

- Q: What are the different surface embossing options for aluminum profiles?

- Aluminum profiles offer a variety of surface embossing options, each with its own unique textures and patterns. Some commonly used options include: 1. Diamond pattern: This option creates a diamond-shaped pattern on the profile's surface, providing both visual appeal and improved grip. It is ideal for applications that require slip resistance. 2. Stucco pattern: Stucco embossing creates a textured surface with small, raised bumps. It is often used in applications where aesthetics play a crucial role, such as architectural facades or interior design elements. 3. Hammer tone pattern: This option gives the aluminum profile a hammered texture, providing a distinctive and rustic appearance. It is popular in decorative applications like furniture or light fixtures. 4. Wood grain pattern: Wood grain embossing mimics the texture and look of natural wood. It is commonly chosen for applications like window frames or doors when a traditional or natural appearance is desired. 5. Linen pattern: Linen embossing creates a subtle, fabric-like texture on the profile's surface. It is frequently used in applications that require a sophisticated and elegant finish, such as interior decorative panels or cabinet doors. It's worth noting that these embossing options can be customized or combined to meet specific design requirements. Manufacturers may offer additional options, allowing customers to choose from a wide range of patterns and textures to achieve their desired aesthetic and functional goals.

- Q: What are the specific requirements or considerations when using aluminum profiles in the construction or design of swimming pools and spas?

- <p>Yes, there are special requirements for using aluminum profiles in swimming pools and spas. These include corrosion resistance to withstand chlorinated water, which is common in pools and spas. Profiles must be made of marine-grade aluminum to prevent rust and ensure longevity. They should also be able to withstand high humidity and temperature fluctuations. Additionally, profiles need to be non-slip and easy to clean to maintain safety and hygiene. The design should also consider structural integrity to support the weight of the pool or spa structure and any associated equipment.</p>

Send your message to us

China Anodized Aluminum Frame Profiles for Alu Profile Extrusion Sliding Window

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords