Aluminum profile extrusion for led light strips

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Aluminium is a relatively soft, durable, lightweight, ductileand malleablemetalwith appearance ranging from silvery to dull gray, depending on the surfaceroughness. It is nonmagnetic and does not easily ignite. A fresh film ofaluminium serves as a good reflector (approximately 92%) of visible lightand an excellent reflector (as much as 98%) of medium and far infraredradiation. The yield strength of pure aluminium is 7–11 MPa,while aluminium alloys have yield strengths ranging from200 MPa to 600 MPa. Aluminium has about one-third the densityand stiffness of steel. It is easily machined,cast, drawn and extruded.

Aluminium alloys (or aluminum alloys; see spellingdifferences) are alloysin which aluminium(Al) is the predominant metal. The typical alloying elements are copper, magnesium,manganese,silicon,tin and zinc. There are twoprincipal classifications, namely casting alloys and wrought alloys, both of which are furthersubdivided into the categories heat-treatableand non-heat-treatable. About 85% of aluminium is used for wrought products,for example rolled plate, foils and extrusions.Cast aluminium alloys yield cost-effective products due to the low meltingpoint, although they generally have lower tensile strengthsthan wrought alloys. The most important cast aluminium alloy system is Al–Si,where the high levels of silicon (4.0–13%) contribute to give good castingcharacteristics. Aluminium alloys are widely used in engineering structures andcomponents where light weight or corrosion resistance is required

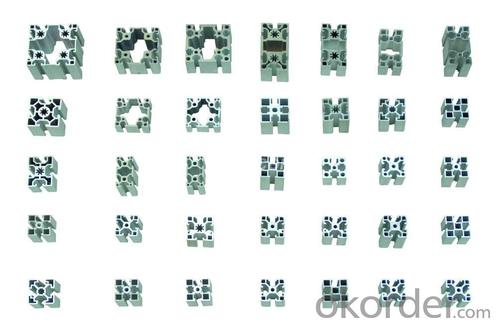

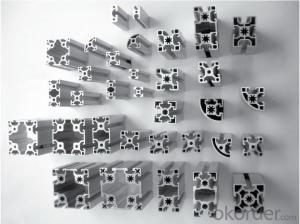

Features:

Material | Alloy 6063,6061,6005or according to customer’s choice |

Temper | T3, T4, T5, T6 |

Surface | Anodize, electrophoresis, powder coating, PVDF coating, wood grain painting, matted, etc. |

Length | Coating 6.5 meters, Anodizing 6.5 meters, Mill finish 5 meters |

Application | Industrial, electrical equipment(TV set, air conditioner, refrigerator, computer), decoration,construction, transportation |

Custom Made | We can package following with customer's request. |

FAQ:

1. What is the form of payment?

Normally 30% TT, L/C at sight

2. Type of quotation?

FOB, CFR, CIF

3. Port of loading?

Shenzhen/Guangzhou port

4. Delivery time?

15-20 days after client’s deposit

- Q: Are there any limitations on the length of aluminum profiles?

- Yes, there are limitations on the length of aluminum profiles. The length of aluminum profiles is typically limited by factors such as the manufacturing process, transportation constraints, and practicality. In terms of manufacturing, aluminum profiles are usually extruded or rolled, and the length is limited by the equipment and capabilities of the manufacturer. Extrusion presses and rolling mills have certain size limitations, which determine the maximum length of aluminum profiles that can be produced. Transportation constraints also play a role in limiting the length of aluminum profiles. Longer profiles may be difficult to transport due to logistical challenges, such as the size of trucks or shipping containers. Moreover, the risk of damage or deformation during transportation increases with longer profiles. Practicality is another factor that imposes limitations on the length of aluminum profiles. Longer profiles may become less rigid and more prone to sagging or bending under their own weight, making them less suitable for certain applications. Additionally, longer profiles may be more difficult to handle and install, requiring specialized equipment and techniques. While there are limitations on the length of aluminum profiles, manufacturers can often produce profiles in various lengths to meet specific project requirements. However, it is important to consider these limitations and consult with the manufacturer to determine the feasibility of producing longer profiles if needed.

- Q: What are the potential safety issues that might arise from using aluminum profiles in construction projects?

- <p>While aluminum profiles are generally safe and widely used in construction due to their strength, lightweight, and corrosion resistance, there are a few safety concerns to consider. These include ensuring proper installation to prevent structural failure, avoiding sharp edges that could cause injury, and ensuring that the aluminum does not react with other materials in a way that could compromise safety. Additionally, it's important to use aluminum profiles that meet building codes and standards to ensure they can withstand the expected loads and environmental conditions.</p>

- Q: How to sell aluminum profile and accessories, how to find customers online?

- Go to the home network. There are all factories inside

- Q: Can aluminum profiles be used in exhibition or trade show displays?

- Yes, aluminum profiles can be used in exhibition or trade show displays. Aluminum profiles provide durability, flexibility, and a sleek appearance, making them a popular choice for constructing exhibition booths and displays. The lightweight nature of aluminum profiles also makes them easy to transport and set up, while still offering structural stability. Additionally, aluminum profiles can be easily customized and adapted to meet specific design requirements, allowing for the creation of unique and eye-catching displays.

- Q: Are aluminum profiles suitable for exhibition booths?

- Yes, aluminum profiles are suitable for exhibition booths. Aluminum is a versatile and lightweight material that offers various benefits for exhibition booth construction. Firstly, aluminum profiles are easy to work with and can be easily cut, drilled, and assembled to create custom booth designs. This flexibility allows for creativity and customization to meet specific booth requirements. Additionally, aluminum profiles are highly durable and long-lasting. They are resistant to corrosion, rust, and other environmental factors, which ensures that the exhibition booth can withstand the rigors of multiple events and maintain its appearance over time. This durability also makes aluminum profiles a cost-effective choice, as they require minimal maintenance and can be reused for future exhibitions. Furthermore, aluminum profiles offer a sleek and professional aesthetic that can enhance the overall presentation of the exhibition booth. The material can be finished with various coatings, such as paint or anodizing, to achieve the desired look and branding. Moreover, aluminum profiles can be easily integrated with other materials, such as glass, acrylic, or fabric, to create visually appealing displays within the booth. Lastly, aluminum profiles provide structural stability while remaining lightweight. This is crucial for exhibitors who need to transport and assemble their booths frequently. The lightweight nature of aluminum profiles makes them easy to handle, reducing logistical challenges and costs associated with booth setup and dismantling. Overall, aluminum profiles offer numerous advantages that make them suitable for exhibition booths. Their versatility, durability, aesthetic appeal, and ease of use make them an excellent choice for exhibitors looking to create eye-catching and functional booth designs.

- Q: What are the different types of extrusion processes used for aluminum profiles?

- There are several types of extrusion processes used for aluminum profiles, including direct extrusion, indirect extrusion, impact extrusion, and hydrostatic extrusion.

- Q: What specific criteria or standards must be met when employing aluminum profiles in commercial construction?

- <p>Yes, there are special requirements for using aluminum profiles in commercial buildings. These include adherence to building codes and regulations, which vary by region. Profiles must meet specific strength and durability standards to ensure structural integrity. They should also comply with fire safety and energy efficiency requirements. Additionally, the profiles need to be resistant to corrosion and weathering, and must be compatible with other building materials. Aesthetic considerations, such as color and finish, are also important to match the building's design. It's crucial to work with certified suppliers and follow proper installation procedures to meet these requirements.</p>

- Q: What are the methods to protect aluminum profiles from corrosion during the installation and usage phases?

- <p>To prevent corrosion of aluminum profiles during installation and use, follow these steps: 1. Choose high-quality aluminum profiles with proper alloy composition that resists corrosion. 2. Ensure the surface is clean and free from contaminants before installation. 3. Apply a protective coating such as a clear anodized finish, powder coating, or paint to the aluminum surface. 4. Avoid contact with corrosive substances like saltwater or chemicals. 5. Regularly inspect and clean the profiles to remove dirt and debris that can lead to corrosion. 6. Use stainless steel fasteners and avoid dissimilar metal contact, as it can accelerate corrosion. 7. Maintain a dry environment to prevent moisture-induced corrosion. By following these practices, you can significantly reduce the risk of corrosion and prolong the lifespan of aluminum profiles.</p>

- Q: This question asks whether aluminum profiles can be recycled and if so, the process involved in recycling them.

- <p>Yes, aluminum profiles can be recycled. The recycling process typically involves collection, sorting, and shredding the aluminum profiles. After shredding, the material is melted in a furnace, which separates impurities and leaves behind pure aluminum. This molten aluminum can then be cast into new profiles or other products. The recycling of aluminum is energy-efficient and environmentally friendly, as it requires only 5% of the energy needed to produce aluminum from raw materials. This makes aluminum recycling a sustainable practice that helps conserve resources and reduce waste.</p>

- Q: Can aluminum profiles be used in aerospace applications?

- Yes, aluminum profiles can be used in aerospace applications. Aluminum is a lightweight, strong, and corrosion-resistant material, making it suitable for various components and structures in the aerospace industry. It is commonly used in aircraft frames, wings, and fuselages due to its high strength-to-weight ratio and excellent mechanical properties. Additionally, aluminum profiles can be easily fabricated and joined, allowing for efficient manufacturing processes in the aerospace sector.

Send your message to us

Aluminum profile extrusion for led light strips

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords