Aluminum T Extrusion Profiles - Cold Rolled Aluminum Sheet Cold Price

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 2 m.t.

- Supply Capability:

- 5000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1.Structure of Product Description

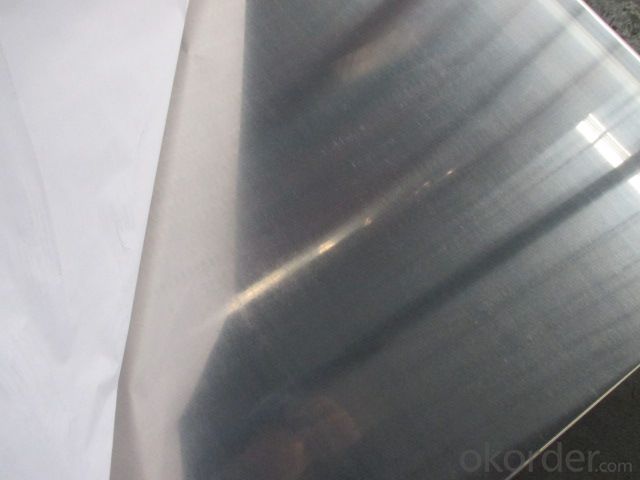

Cold rolled aluminum sheet and cold rolled stainless steel sheet are all widely used in the field of construction field and decoration field, etc.

There are many different grades, su cnbm INTERNATONAL copratoion mainly goods are all including ch as: 1000 series, 2000 series, 3000 series, 5052,5754,5083,6061,6063,8011, etc.

The temper is include H14, H22, H24, H44,H112,H114,etc.

2. Main features of the product

a. Competitive price

b. Frist-Class Service.

c. Shortest service.

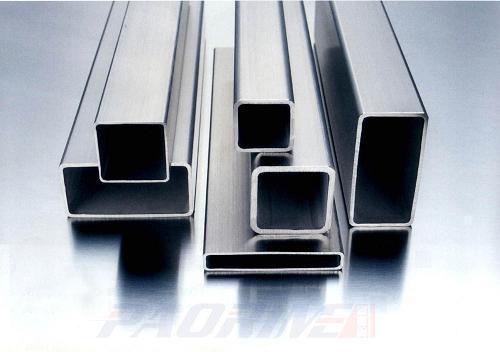

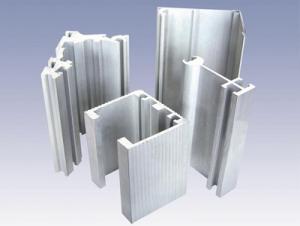

3. Image.

4. Product detailed sizes:

1000mm*2000mm, 1219mm*2438mm,1220mm*2440mm, 1000*1000MM,

1250mm*2500mm,1500mm*3000mm, etc.

5. FAQ:

What is the quality standard?

---Usually our standard is GB3880-2006 or others.

What is the width range?

---It is from 1000mm to 2500mm, etc.

---Normally it is around 9000 tons totally.

Where is your client from?

---Normally it is from Japan, USA, ENGLAND, SINGAPORE, ETC.

What is your mainly products?

---Normally they are aluminum sheet, checkered sheet, mirror finish aluminium sheet, aluminum casting coil, etc.

- Q: Can aluminum profiles be used for framing mirrors?

- Yes, aluminum profiles can be used for framing mirrors. Aluminum is a versatile and lightweight material that provides a sleek and modern look to any mirror frame. It is commonly used in various industries, including architecture and interior design, due to its durability, corrosion resistance, and ease of customization. Aluminum profiles come in a variety of shapes and finishes, allowing for endless design possibilities to match any style or decor. Additionally, aluminum frames are easy to install and maintain, making them a popular choice for framing mirrors in both residential and commercial settings.

- Q: Are there any specific maintenance requirements for aluminum profiles?

- Yes, aluminum profiles require regular maintenance to ensure their longevity and performance. This includes cleaning the profiles regularly to remove dirt, dust, and debris. It is also important to check for any signs of corrosion or damage and address them promptly. Additionally, lubricating moving parts and hinges can help to maintain smooth operation. Finally, following the manufacturer's guidelines and recommendations for maintenance is essential to keep the aluminum profiles in optimal condition.

- Q: How do you prevent discoloration or fading of aluminum profiles?

- To prevent discoloration or fading of aluminum profiles, it is important to apply a protective coating or finish on the surface of the profiles. This can be done using methods such as anodizing, powder coating, or painting. These coatings act as a barrier, shielding the aluminum from exposure to UV rays, moisture, and other environmental factors that can cause discoloration and fading. Regular cleaning and maintenance also play a crucial role in preventing discoloration, as removing dirt, grime, and pollutants promptly can help preserve the appearance and integrity of the aluminum profiles.

- Q: Can aluminum profiles be used in solar panel installations?

- Solar panel installations can utilize aluminum profiles, which are favored in construction and engineering due to their lightweight, durability, and resistance to corrosion. These properties make aluminum profiles an ideal material for solar panel installations. Aluminum profiles can be employed to construct robust frames that securely hold solar panels in place. The lightweight nature of aluminum facilitates easy transportation and installation of the panels, reducing overall installation time and cost. Moreover, the corrosion resistance of aluminum ensures that the frames withstand exposure to various weather conditions, making them suitable for both residential and industrial installations. In addition, aluminum profiles can be easily customized and fabricated to meet specific project requirements. They can be extruded into various shapes and sizes, allowing flexibility in designing frames to accommodate different panel dimensions and orientations. Anodizing or powder coating can also be applied to aluminum profiles for added protection against environmental factors and to enhance the installation's aesthetic appeal. To summarize, aluminum profiles are an excellent choice for solar panel installations. Their lightweight nature, durability, resistance to corrosion, and customization options make them suitable for a wide range of applications, ensuring the longevity and efficiency of the solar panel system.

- Q: Can aluminum profiles be utilized in creating distinctive architectural designs and styles?

- <p>Yes, aluminum profiles can be used to create unique architectural designs and styles. They are favored for their strength, durability, and versatility. Architects can manipulate aluminum to achieve a wide range of shapes and structures, from sleek modern designs to traditional styles with a contemporary twist. Aluminum's lightweight nature and resistance to corrosion make it an ideal material for both interior and exterior applications, allowing for creative freedom in architectural expression.</p>

- Q: This question asks for an overview of the various types of aluminum profiles that are frequently utilized in the field of commercial construction.

- <p>Commonly used aluminum profiles in commercial construction include: 1. Extruded aluminum profiles, which are versatile and can be customized for various applications. 2. Structural aluminum framing, used for building structures and curtain walls. 3. Aluminum window and door frames, known for their durability and energy efficiency. 4. Aluminum handrails and railings, important for safety in commercial buildings. 5. Aluminum trusses, used for roof structures and large spans. 6. Aluminum angles and channels, used for support and framing. 7. Aluminum tubes, used in various structural and decorative applications. These profiles are chosen for their strength, lightweight, corrosion resistance, and ease of maintenance.</p>

- Q: The user is asking if it's possible to use recycled aluminum to create new aluminum profiles.

- <p>Yes, recycled aluminum can be used to produce new aluminum profiles. The process of recycling aluminum is energy-efficient and environmentally friendly, as it requires significantly less energy compared to producing aluminum from raw materials. Recycled aluminum maintains the same properties as new aluminum, making it suitable for manufacturing various aluminum profiles. The recycling process typically involves melting the aluminum, which can then be cast into new shapes and forms, including profiles for construction, automotive, and other industries. This not only conserves resources but also reduces waste and carbon emissions.</p>

- Q: This question asks if aluminum profiles can be utilized in the construction of environmentally friendly buildings.

- <p>Yes, aluminum profiles can be used for green building applications. They are valued for their durability, recyclability, and energy efficiency. Aluminum is lightweight, which reduces the building's carbon footprint during transportation. It also has excellent thermal conductivity, allowing for better insulation and energy conservation. Additionally, aluminum can be recycled without losing its properties, contributing to a circular economy and reducing waste. These characteristics make aluminum profiles suitable for sustainable construction practices.</p>

- Q: Can aluminum profiles be an alternative to wood in construction?

- Yes, aluminum profiles can be a viable alternative to wood in construction. Aluminum profiles offer several advantages over wood, making them a popular choice in many construction projects. Firstly, aluminum profiles are lightweight yet strong, allowing for easy handling and installation. This characteristic makes them suitable for various applications, including frames for doors, windows, curtain walls, and partitions. Additionally, aluminum profiles have excellent durability and resistance to weathering, corrosion, and pests, making them a long-lasting and low-maintenance option. Furthermore, aluminum profiles have inherent fire-resistant properties, which can enhance safety in construction. Unlike wood, aluminum does not burn, and it has a high melting point, making it less likely to contribute to the spread of fires. In terms of sustainability, aluminum profiles can offer environmental benefits. Aluminum is a highly recyclable material, meaning that it can be reused and repurposed multiple times without losing its properties. This recyclability reduces the environmental impact associated with construction projects and supports the circular economy. Another advantage of using aluminum profiles is their design versatility. Aluminum can be easily shaped and extruded into various profiles and sizes, allowing for customization and flexibility in architectural designs. This adaptability makes aluminum profiles suitable for both functional and aesthetic purposes in construction. However, it is important to note that aluminum profiles may have higher upfront costs compared to wood. Additionally, the thermal conductivity of aluminum is higher than that of wood, which means that aluminum profiles may require additional insulation to provide optimal thermal performance. In conclusion, aluminum profiles can be a viable alternative to wood in construction due to their lightweight, durability, fire resistance, sustainability, and design versatility. While there may be some considerations regarding cost and thermal conductivity, the benefits of aluminum profiles make them an attractive option for various construction applications.

- Q: Is it feasible to recycle aluminum profiles and what factors affect the recycling process?

- <p>Yes, aluminum profiles can be recycled easily. Aluminum is one of the most recycled materials globally due to its low melting point, which requires less energy for recycling compared to other metals. The recycling process involves melting the aluminum, which can be done at temperatures significantly lower than those needed for other metals. Additionally, aluminum retains its properties even after multiple recycling cycles, making it an ideal material for sustainable use. The recycling rate of aluminum is high, and it contributes to energy savings and reduced environmental impact. However, the ease of recycling can be affected by factors such as the presence of impurities, the complexity of the profile shapes, and the efficiency of collection systems.</p>

Send your message to us

Aluminum T Extrusion Profiles - Cold Rolled Aluminum Sheet Cold Price

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 2 m.t.

- Supply Capability:

- 5000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords