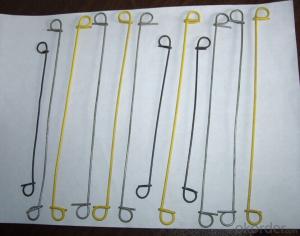

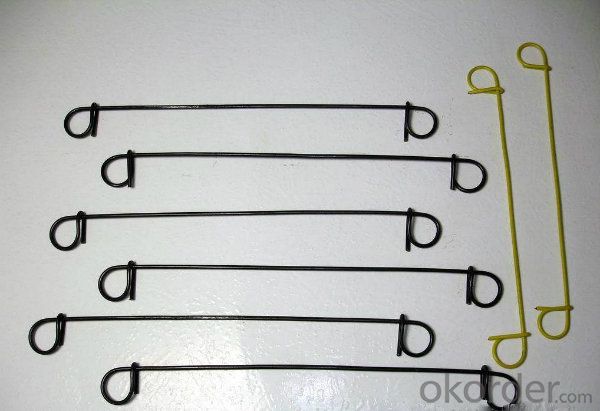

Galvanized Iron Wire Galvanized Double Loop Tie Wire

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 50000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

1.Product Description

Wire style:

Electro Galvanized Iron Wire

Hot Dipped Galvanized Iron Wire

Use:

Mainly used in communication equipment, medical equipment and weaving nets, brushes, cables, filters, high pressure pipe, construction, handicrafts and other industries.

we can be made according to customers specific requirements

Features of Galvanized Wire:

Material: low carbon steel wire

Tensile Strength: 400--580Mpa

Standard wire gauge for electro galvanized iron wire: From 8# to 16#

Hot-DIP galvanized iron wire standard wire gauge: From 8# to 24#

Tie wire is a metal wire product that used to tie bags, Also known as bag tie wire.

1)Material: black iron wire, galvanized wire , PVC coated wire, stainless steel wire.

2)Wire diameter: 0.5MM-4.0MM.

3)Lenght: 10-25cm.

4)Packaging: plastic bags, cardboard boxes, trays, etc. Or according to customer requirement.

4.Black Annealed Iron Wire Specification

Wire Gauge | SWG(mm) | BWG(mm) | Metric(mm) |

8 | 4.05 | 4.19 | 4.00 |

9 | 3.66 | 3.76 | 4.00 |

10 | 3.25 | 3.40 | 3.50 |

11 | 2.95 | 3.05 | 3.00 |

12 | 2.64 | 2.77 | 2.80 |

13 | 2.34 | 2.41 | 2.50 |

14 | 2.03 | 2.11 | 2.50 |

15 | 1.83 | 1.83 | 1.80 |

16 | 1.63 | 1.65 | 1.65 |

17 | 1.42 | 1.47 | 1.40 |

18 | 1.22 | 1.25 | 1.20 |

19 | 1.02 | 1.07 | 1.00 |

20 | 0.91 | 0.84 | 0.90 |

21 | 0.81 | 0.81 | 0.80 |

22 | 0.71 | 0.71 | 0.70 |

- Q: Three parallel wires are each carrying a 4A current. ; wire A) is 6 mm from wire B) which is 3mm from wire C); The current in wires B and C are out of the paper, while A is into the paper. What is the magnitude and direction of the magnetic field halfway between wires A and B?I have tried using Biot-Savart Law but keep getting it wrong can someone please help? I also have an equation for two parallel wires but how do I relate it to two?

- You can use the Biot-Savart Law, but it is confusing and kind of a waste of your time and space. For straight wires, someone ALREADY worked out the Biot-Savart Law. See the following link for the result: hyperphysics.phy-astr.gsu.edu/Hba... The formula of interest for us is B = mu0*I/(2*Pi*r) where mu0 is magnetic permeability of free space, I is current, and r is distance from the wire carrying the current. B is the magnetic field due to that PARTICULAR wire. To deal with three wires, use a superposition principle and stack magnetic fields on top of each other. Do be aware of direction: remember the right hand rule. RH rule for magnetic fields in vicinity of wires: point thumb in direction of current, curl fingers to show the magnetic field circulation direction. Use this sign convention: + B is up along page, -B is down along page For Wire A: point of interest is r = d_ab/2 or 0.003 m to the right of wire A Point thumb in to the paper and the finger curl indicates that B_A is downward B_A = -mu0*I_A/(pi*d_ab) For Wire B: point of interest is r = d_ab/2 or 0.003 m to the left of wire B Point thumb out of the paper and the finger curl indicates that B_B is downward B_B = -mu0*I_B/(pi*d_ab) For wire C: point of interest is r = d_ab/2 + d_bc or 0.006 m to the left of wire C Point thumb out of the paper and the finger curl indicates that B_C is downward B_C = -mu0*I_C/(2*pi*(d_ab/2 + d_bc)) Add up: Bnet = B_A + B_B + B_C Bnet = -mu0*I_A/(pi*d_ab) - mu0*I_B/(pi*d_ab) - mu0*I_C/(2*pi*(d_ab/2 + d_bc)) Simplify: Bnet = -mu0/pi*(I_A/d_ab + I_B/d_ab + I_C/(d_ab + 2*d_bc)) data: mu0:=4*Pi*10^(-7) Tesla-m/A; I_A:=4 A; I_B:=4 A; I_C:=4 A; d_ab:=0.006 m;d_bc:=0.003 m; Result: Bnet = -6.667 milliTeslas negative sign indicates downward direction.

- Q: I am moving a stove that has four wires - bare copper (ground), red, white, and black.The location I am putting it in only has three wires - red, white, and black.Can I just ignore the ground on the new location since it doesn't have one? Or should I cross one of the other wires with the ground?

- Your four-wire stove has a terminal where you can connect the bare/green and white wires together, most have a jumper to connect the two terminals. You don't want to leave any wires unconnected. The other two wires (red black) are connected the same way between 3-wire and 4-wire units. You'll have to buy a 3-wire cable for your stove to plug it into the 3-wire receptacle. The new code requires 4-wire connections. The bare/green wire and the white neutral wire are run back to the circuit breaker panel separately at which point the are connected together on a buss bar.

- Q: I purchased a wiring harness to install an aftermarket receiver in my 2000 Chevy Cavalier, also. I have lost the insert that came with the harness and as such I am at a loss as to how to wire my receiver to the harness.help

- 2000 Chevrolet Cavalier Car Stereo Radio Wiring Diagram Car Radio Constant 12v+ Wire: Orange Car Radio Switched 12v+ Wire: Ignition Switch (The radio harness does not provide a switched power source. Run a wire from the Ignition Switch.) Car Radio Ground Wire: Black Car Radio Illumination Wire: Gray Car Stereo Dimmer Wire: N/A Car Stereo Antenna Trigger: Pink Car Stereo Amp Trigger Wire: N/A Car Stereo Amplifier Location: N/A Front Speakers Size: N/A Front Speakers Location: N/A Left Front Speaker Positive Wire (+): Tan Left Front Speaker Negative Wire (-): Gray Right Front Speaker Positive Wire (+): Light Green Right Front Speaker Negative Wire (-): Dark Green Rear Speakers Size: N/A Rear Speakers Location: N/A Left Rear Speaker Positive Wire (+): Brown Left Rear Speaker Negative Wire (-): Yellow Right Rear Speaker Positive Wire (+): Dark Blue Right Rear Speaker Negative Wire (-): Light Blue

- Q: for christmas im getting my dad an outdoor speaker system buttheunder groung wire costs ALOT so i was wondering if regular speaker wire will work fine if i used it and burried?

- Regular speaker wire will work for a short time, but the insulation is not designed to be used underground. It will deteriorate and short out. Your other option is to use conduit, but that will probably be more expensive that the underground wire. Wire for low voltage lights will work, but the gauge is fairly small, so not much power can me pushed through the wire. There is voltage present in speaker lines, about 32-40v

- Q: What are the effects on an amp when you use power/ground wires that are too small? I bought a set of 8 guage wires off of OKorder, and it stated they can handle up to 1000W. I'm using a Kenwood KAC-9103D amp, 500x1 @ 4ohms, 900x1 @ 2ohms, and 900+ x1 @1ohm (1800 W max power). My subs are Kicker VR8, dual voice coil, 4ohms, wired in parallel. Was it a mistake to go with 8 guage wiring? Should have I gone with 4 guage?

- Using smaller wires will cause your wire to heat . As the wire gets hot conductivity decreases giving less current to the amp. It seems like you are spending some money for the equipment i would use a 4 gauge to protect your investment. I have seen people car catching fire because of bad audio wiring

- Q: What is the wiring for one headlight on a fourwheeler that has high and low beams.

- Year? Make? Model# ? If it has 1 headlight with a high low beam, the bulb has 2 filaments.

- Q: If you hang a pot-plant with mass of 8kg from two lengths of wire attached to a horizontal beam 100cm apart. The wire on the left has a length of 50cm and the wire on the right has a length of 75cm.What is the tension in both wires?

- The tension in both wires.? If you hang a pot-plant with mass of 8kg from two lengths of wire attached to a horizontal beam 100cm apart. The wire on the left has a length of 50cm and the wire on the right has a length of 75cm. What is the tension in both wires? In the triangle ABC, AB(c) = 100 cm, BC (a) = 50 cm and AC (b) = 75 cm 2s = a+b+c = 225 cm s = 112.5 s-a = 112.5 - 50 = 62.5 s-b = 112.5 - 75 = 37.5 s-c = 112.5 - 100 = 12.5 tan A/2 = √ {(s-b)*(s-c) / [s*(s-a)] = √ {37.5*12.5) / [112.5*62.5] A = 28.95? tan B/2 = √ {(s-c)*(s-a) / [s*(s-b)] = √ {12.5*62.5) / [112.5*37.5] B = 46.57? C = 180-28.95-46.57 =104.48? --------------------------------------... 46.57? is the angle between horizontal and 50 cm wire. 28.95 is he angle between horizontal and 100 cm P is the tension in the 50 cm wire and Q is the tension in the 75 cm wire Equating the horizontal components of the tensions P cos 46.57? = Q cos 28.95 ? P = Q cos 28.95 ?/ cos 46.57? P = 1.27 Q-------------------1 Equating the sum of the vertical components of the tensions to the weight of the pot P sin 46.57? + Q sin 28.95 = 8*9.8 N 0.73P + 0.48 Q = 78.4N 0.73(1.27 Q) + 0.48 Q = 78.4N Q = 55.72 N and P = 70.76 N ============================= Or use Lamis theorm Angle between P and Q = 104.48? Angle between P and the pot = 90 + 46.57? Angle between Q and the pot = 90 + 28.95 By Lamis theorm P/ cos 46.57? = 78.4/ sin 104.48? P = 55.67 N and Q = (78.4/ sin 104.48? ) cos28.95 = 70.85N ====================================

- Q: I needed a new tail light for my trailer. The aftermarket tail lights only came with two wires sticking out the back, one red and one black. The stock tail light that broke had 3 wires and so does the harness on the trailer end. People have told me that even though it is different it will work. Do I join the two hot wires together with the red wire and then the return wire to the black? There is no wiring diagram avalible and I dont have the money to replace then entire lighting system. Thanks for your help.

- Pull the lens and look at the bulb. If it is a 2 element bulb then it will work, if it is a single element it will not. If it is a 2 element then one of the wires is turn and stop light and the other is tail light. It will use a body ground in that case. On your trailer harness you will have a brown wire, that is tail lights, the turn and stop light (same wire) will be either green or yellow depending on what side of the trailer you are on. The white wire is ground. The turn and stop light will be much brighter than the tail light so just twist the wires together and see which is which. You can hook the white wire to the mounting screw of the light fixture to be sure you have a good ground.

- Q: I need the wiring diagram for the 1992 Lexus ES300 OE Stereo.I specifically need to know what colors (or numbers) the wires are for the front right and front left bottom door speaker.

- Here ya go, 1994 Lexus ES300 Car Audio Wiring Diagram Car Radio Battery Constant 12v+ Wire: Gray Car Radio Accessory Switched 12v+ Wire: Blue/Red Car Radio Ground Wire: Brown Car Radio Illumination Wire: Pink/Blue Car Stereo Dimmer Wire: N/A Car Stereo Antenna Trigger Wire: N/A Car Stereo Amp Trigger Wire: Pink/Blue Car Stereo Amplifier Location: Right of the glove box. Car Audio Front Speakers Size: N/A Car Audio Front Speakers Location: N/A Left Front Speaker Positive Wire (+): Blue Left Front Speaker Negative Wire (-): White Right Front Speaker Positive Wire (+): Black Right Front Speaker Negative Wire (-): White Car Audio Rear Speakers Size: N/A Car Audio Rear Speakers Location: N/A Left Rear Speaker Positive Wire (+): Yellow Left Rear Speaker Negative Wire (-): White Right Rear Speaker Positive Wire (+): Green Right Rear Speaker Negative Wire (-): White Note: White is the common ground for the signal going to the amplifier. Good Luck!

- Q: I am making a lamp shade that calls for bonsai wire. How is bonsai wire different from regular wire and what would be a good substitute for it????

- Aluminum or copper are the best choices. Avoid iron or steel as they can react with the sap and harm the tree, especially a juniper. bonsai is a copper coated aluminum. Aluminum is more mallable, copper is stronger, with strength you can go thinner, but thin is harder on the tree.

Send your message to us

Galvanized Iron Wire Galvanized Double Loop Tie Wire

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 50000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches