Galvanized Corrugated Steel Sheet for Roofing Type Galvanized steel Plain Sheet

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 40 m.t.

- Supply Capability:

- 1000000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Description of Corrugated Iron Sheet:

Standard: GB/T 12754-2006;ASTM A 755;EN 10169;JIS G 3312;AISI;BS;DIN Grade: SGCC,SGCH,G550,DX51D,DX52D,DX53D

Specifications of Corrugated Iron Sheet:

| Product Name | Wave Tile |

| Standard: | GB , ASTM , JIS etc |

| Raw Material | GI , GL , PPGI , PPGL |

| Thickness | 0.15mm-0.6mm |

| Width | 750mm-1000mm(BC)/665-920mm(AC) |

| Length | 4000mm(Max) |

| Coating | AZ40-AZ160g , Z50-Z140g |

| Temper | Full hard , half hard , annealed |

| Spangle | Regular , Minimized , Big spangle |

| Pallet Weight: | 2-4mt |

| Material | SGCH , SGLCH , SGCC |

| Payment: | Trade Assurance OF Alibaba ,T/T, L/C at sight |

| MOQ: | 20 ton each size, 1x20'ft per delivery |

Features of Corrugated Iron Sheet:

various roofs or walls referring to the large size factory buildings, storages, exhibition halls, gymnasiums etc.

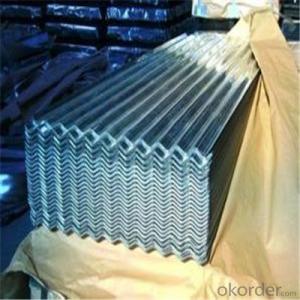

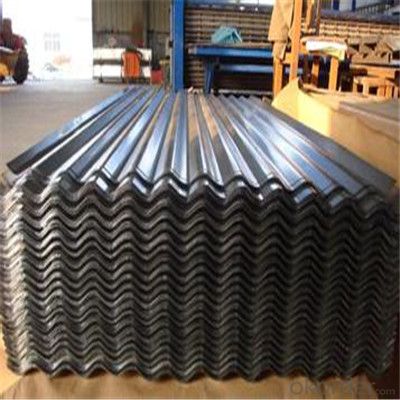

Images of Corrugated Iron Sheet:

FAQ:

1. What's the Delivery port?

The main ports are Qingdao and Tianjin, we also can deliver to other ports to meet your requirements

2. How long is the lead time?

Delivery time: 45 days after order confirmed.

3. What payment term do you accept?

Payment: T/T or L/C at sight.

- Q: Can steel sheets be used in marine applications?

- Yes, steel sheets can be used in marine applications. Steel is a common material used for constructing ships, offshore platforms, and other marine structures due to its high strength, durability, and resistance to corrosion in saltwater environments.

- Q: How do steel sheets perform in terms of dimensional stability?

- Steel sheets are known for their excellent dimensional stability. This means that they are highly resistant to changes in size or shape when subjected to external forces or fluctuations in temperature. Steel is inherently strong and rigid, allowing it to maintain its shape and dimensions over extended periods of time. Additionally, steel sheets have low thermal expansion coefficients, meaning they expand and contract minimally with changes in temperature. This characteristic further enhances their dimensional stability, making them suitable for applications where precise dimensions and consistent performance are critical. Steel sheets are widely used in various industries, including construction, automotive, and manufacturing, due to their reliable dimensional stability.

- Q: How do steel sheets perform in weather resistance?

- Steel sheets are highly resistant to weather conditions, including extreme temperature variations, moisture, and UV radiation. They form a protective layer that prevents corrosion, ensuring their durability and longevity even in harsh outdoor environments.

- Q: Can steel sheets be used for automotive suspension components?

- Yes, steel sheets can be used for automotive suspension components. Steel offers high strength and durability, making it a suitable material for the suspension system, which withstands significant loads and impacts. Steel sheets can be shaped and formed into various suspension components such as control arms, springs, and stabilizer bars, providing the necessary structural support and stability required for a vehicle's suspension system.

- Q: Are the steel sheets available in different grades?

- Yes, steel sheets are available in different grades.

- Q: Are the steel sheets resistant to impact or bending?

- Yes, steel sheets are generally resistant to both impact and bending. Steel is known for its high strength and durability, making it less likely to be affected by external forces such as impacts or bending. This is due to the material's ability to absorb and distribute the energy applied to it, resulting in minimal deformation or damage. However, the specific resistance to impact and bending may vary depending on the thickness, type of steel, and any additional treatments or coatings applied to the sheets.

- Q: Can steel sheets be used in the manufacturing of appliances?

- Appliances can indeed incorporate steel sheets into their manufacturing process. The manufacturing industry heavily relies on steel due to its exceptional qualities of strength, durability, and versatility. Steel sheets can be manipulated to fit various sizes and designs, catering to the unique specifications of different appliances. Furthermore, steel exhibits resistance against corrosion, rendering it suitable for appliances that may encounter water or other liquids. Additionally, steel serves as an exceptional conductor of heat, proving advantageous for appliances that necessitate efficient heat transfer. Consequently, steel sheets are widely employed in the fabrication of appliances, including refrigerators, ovens, dishwashers, washing machines, and numerous others.

- Q: Are steel sheets resistant to termites or pests?

- No, steel sheets are not resistant to termites or pests as they do not provide any nutritional value to these organisms.

- Q: The difference and usage of color steel sandwich panel and color profiled steel sheet

- The sandwich panel consists of three parts: two upper and lower forming steel plates, the middle core plate (rock wool, polystyrene, polyurethane), thick 50mm/75mm/100mm, steel strip on both sides. Wall panels and shingles used primarily for movable rooms and various large plants.

- Q: What factors affect the cost of steel sheets?

- Several factors affect the cost of steel sheets, including the current market demand and supply, raw material prices, manufacturing and processing costs, transportation and logistics expenses, as well as any applicable trade tariffs or taxes. Additionally, factors such as the type and quality of steel, size and thickness of the sheets, as well as any special finishes or coatings required, can also impact the overall cost.

Send your message to us

Galvanized Corrugated Steel Sheet for Roofing Type Galvanized steel Plain Sheet

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 40 m.t.

- Supply Capability:

- 1000000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords