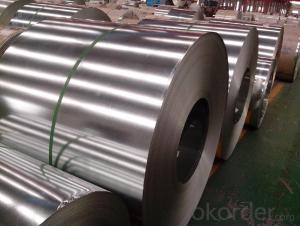

Galvanized Sheet Coil/GI Sheet/galvanized Steel Sheet

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 500 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

deformed steel bar grade 40

material: HRB400, BS4449 GR460B

size: 8-36mmx12m.

short delivery time by bulk or container

deformed steel bar grade 40

material: HRB400, BS4449 GR460B

size: 8-36mmx12m.

short delivery time with bulk or container

packing: Mill standard export packing in bundles/coil, around 2tons/bundle.

country of Origin: China

delivery Time: Within a 35 days

Shipment: by bulk vessel or by container

Leading goods:

section steel:angles,channels,I-beam,H-beam;

coils:cold/hot rolled coils,PPGI,galvanized coils,plate,checkered plate,cutting steel plate,steel strip;

wire rod:steel wire,deformed wire,bar;

pipe:seamless pipe,rectangular pipe,welded pipe,spiral welded pipe,pipe fittings;

stainless steel:steel sheets,stainless steel strips,stainless bar,stainless tube;

special:weathering steel,shipbuilding steel;

construction steel:C-channel,Z-channel,T-bar,high-speed divider plate,corrugated steel plate,steel grating.

Advantage:

We are the spot supplier, Six huge warehouses which can hold 20,000 MT goods.

It makes the cost lower than others,we can provide the competitive price for you.

Delivery time:

Normal sizes can be provided in 7days, the others should be ready in 30---45 days.

Further treatment:

We can offer cutting,painting,drilling holes,bending,threading, welding,galvanization,packing etc.

Security interest:

We have already passed the ISO9001, BV and SGS authentication which makes the quality secured.

If you have the interest in any of the products we can provided, pls don't hesitate to connect with me. Looking forward to cooperate with you.

FAQ of Steel Deformed Bar

1. More than 10 years experience in this industry

2. 100,000 tons exporting per month

3. Professional foreign trade tea

4. OEM&ODM capacity

5. High quality assured & competitive price

6. Try our best to meet your needs & save your budget

7. Very popular in Southeast Asia, Africa, Mid-East and South America etc.

8. VIP membership system, first time customers and long-term cooperation customers can get extra discount on some products.

Cold-rolled stainless steel sheet hot-rolled coil is crude and rolled under low temperature conditions. Because there will be no high-temperature processing, for this procedure in the production process, so people often referred to as its cold-rolled steel. Higher than the hardness of cold-rolled steel hot-rolled, cold-rolled stainless steel sheet so the texture is hard, not suitable for a large number of deep-processing.

In accordance with the organizational characteristics of steel

In accordance with the organizational characteristics of stainless steel sheet to divide, then we would more complicated than in accordance with the production process to divide. But they can be roughly divided into five categories, namely: austenitic sheet, plate ferritic, austenitic - ferritic sheet, plate martensitic precipitation hardening stainless steel sheet plate these five categories. Here we will highlight five categories of stainless steel sheet own characteristics.

Austenitic stainless steel sheet contains chromium, a small amount of molybdenum, titanium, nickel and other elements, so that the hardness and plasticity are high, life is widely used.

The amount of chromium-containing ferritic stainless steel sheet is about twice as austenitic. Thus, the ferritic stainless steel sheet hardness, corrosion resistance, anti-oxidation properties better than austenitic stainless steel sheet, but its disadvantage is poor machinability, commonly used as some special parts production.

Austenitic - ferritic stainless steel sheet is compatible with austenitic - ferritic stainless steel plate advantages, a variety of performances are relatively good, and life applications are particularly widespread.

- Q: Can the steel sheets be easily folded or creased?

- It is not possible to easily fold or crease steel sheets. Steel, being a robust and inflexible material, demands considerable force for bending or creasing. Its durability and resistance to deformation make it a popular choice in construction and manufacturing. Nevertheless, if the steel sheets are sufficiently thin, they might have enough malleability to be bent or creased by utilizing suitable tools and techniques.

- Q: How do steel sheets perform under heavy loads?

- Steel sheets perform exceptionally well under heavy loads. Due to their high strength and durability, they can withstand significant amounts of pressure without deforming or failing.

- Q: What is the difference between a galvanized and aluminized steel sheet?

- The durability and corrosion-resistant properties of galvanized steel and aluminized steel sheets make them widely used in various industries. However, there are notable distinctions between the two. Galvanized steel sheets have a layer of zinc coating that safeguards the underlying steel from rust and corrosion. This process, called galvanization, can be accomplished by immersing the steel sheet in a bath of molten zinc or by electroplating a zinc-rich coating. The zinc layer acts as a sacrificial barrier, meaning it will corrode before the steel, providing excellent rust protection. Galvanized steel finds common usage in outdoor applications like roofing, fences, and automobile parts. In contrast, aluminized steel sheets are coated with an aluminum-silicon alloy layer. This process, known as aluminization, involves immersing the steel sheet in a bath of molten aluminum or applying a thin layer of aluminum-silicon alloy through a continuous hot-dip process. The aluminum-silicon coating offers remarkable heat resistance and corrosion resistance. Aluminized steel is commonly employed in applications where high temperatures are present, such as automotive exhaust systems, heat exchangers, and ovens. To summarize, the primary distinction between galvanized and aluminized steel sheets lies in the type of coating applied to the steel. Galvanized steel is coated with zinc, providing outstanding rust protection, while aluminized steel is coated with an aluminum-silicon alloy, offering superior heat and corrosion resistance. The choice between the two depends on the specific requirements of the application, such as the presence of high temperatures or the need for long-lasting rust protection.

- Q: Can steel sheets be used for elevator panels or interiors?

- Yes, steel sheets can be used for elevator panels or interiors. Steel is a durable and versatile material that is commonly used in elevator construction due to its strength and aesthetic appeal. It can be fabricated into various shapes and sizes to create sleek and modern elevator panels and interiors.

- Q: What is the average thermal conductivity of steel sheets?

- The average thermal conductivity of steel sheets can vary depending on various factors such as the specific type or grade of steel, its composition, and temperature. However, on average, the thermal conductivity of steel sheets ranges between 15 and 30 Watts per meter-kelvin (W/m·K). This means that steel sheets are relatively good conductors of heat, allowing them to efficiently transfer thermal energy across their surfaces. It is important to note that the actual thermal conductivity of a specific steel sheet can be determined through laboratory testing or by consulting technical specifications provided by the manufacturer.

- Q: Can steel sheets be used for automotive manufacturing?

- Certainly, steel sheets have the ability to be employed in automotive production. The automotive sector extensively utilizes steel due to its robustness, longevity, and cost efficiency. Steel sheets find common application in diverse automotive constituents like body panels, chassis, frames, and structural reinforcements. They offer the essential strength and stiffness necessary to ensure the safety and functionality of vehicles. Furthermore, steel sheets can be effortlessly shaped and molded into various forms, rendering them appropriate for intricate automotive designs. Additionally, steel is easily obtainable, hence making it a favored option for automotive manufacturers.

- Q: How are steel sheets measured for thickness?

- Thickness of steel sheets is commonly determined using either a gauge or caliper. The gauge system, which assigns a numerical value to represent thickness, is the most widely used method. In this system, a higher gauge number indicates a thinner sheet. For instance, a 14-gauge steel sheet is thicker than a 20-gauge sheet. To measure thickness with a gauge, a tool called a sheet metal gauge is employed. It comprises notches or slots that correspond to specific gauge numbers. By placing the gauge against the edge of the steel sheet, the appropriate slot indicates its thickness. Alternatively, a caliper can be utilized to measure steel sheet thickness. This precision instrument has two adjustable jaws to accurately measure the distance between them. When measuring a steel sheet's thickness with a caliper, the jaws are gently closed around the sheet, and the measurement is obtained from the caliper's display. Both the gauge and caliper methods offer precise measurements of steel sheet thickness, facilitating manufacturers, engineers, and other professionals in selecting the suitable sheet for their specific applications.

- Q: What is the price range of steel sheets?

- The price range of steel sheets can vary greatly depending on factors such as the type of steel, thickness, size, and market demand. It is advisable to check with suppliers or conduct research to get specific and up-to-date pricing information.

- Q: What are the different strength properties of steel sheets?

- The strength properties of steel sheets can vary depending on factors such as the grade of steel, the thickness of the sheet, and the manufacturing process used. Generally, steel sheets exhibit high tensile strength, which enables them to withstand heavy loads and resist deformation. They also possess good yield strength, indicating their ability to withstand a significant amount of stress before permanent deformation occurs. Additionally, steel sheets generally have excellent hardness, allowing them to resist wear and abrasion.

- Q: Can steel sheets be used in food processing or medical applications?

- Yes, steel sheets can be used in food processing and medical applications. Stainless steel, in particular, is commonly used in these industries due to its corrosion resistance, durability, and ease of cleaning. It is a hygienic material that does not react with food or medical substances, making it suitable for direct contact with these products.

Send your message to us

Galvanized Sheet Coil/GI Sheet/galvanized Steel Sheet

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 500 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords