CORRIGATED SHEET

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

You Might Also Like

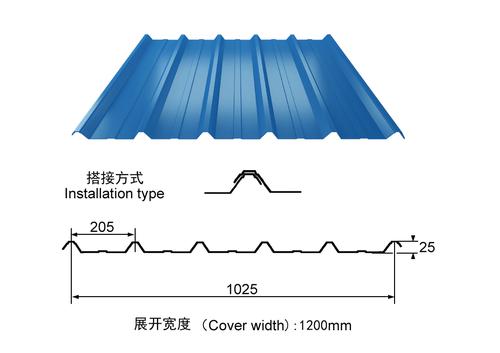

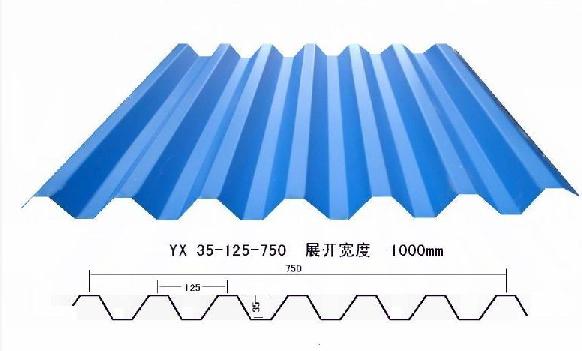

Product Name:corrugated steel roofing sheet

Effective Width:650mm to 1250mm

Thickness:0.13mm-0.8mm

Material PPGI/PPGL steel coil

Coating:Z30-Z275,AZ30-AZ180

Color:white,blue or any RAL colors

length:1m-11.8m according to the container

top color coating:12um-25um

Back color coating:7um-10um

HRB:50-95

Base plate:PRE-PAINTED ALUZINC STEEL COIL,PRE-PAINTED GALVANIZED STEEL COIL

- Q: Why can steel HPB300, steel plate without Q300, steel structure manuscript review, but also continued the Q235, why not improve it?

- HPB's full name is hot rolled round steel (HPB is Hot-rolled Plain Steel Bar) in English, commonly known as wire rod, diameter 6 - 12 rounds of the most common, including HPB235 and HPB300. You haven't met HPB400?. HRB400 and RRB400 are treated steel bars in order to have such high strength. But the general strength, ductility will be reduced, as the saying goes, "tossing" is not resistant to toss about.

- Q: What are the common sizes of steel sheets?

- The common sizes of steel sheets vary depending on the application and industry. However, some standard sizes for steel sheets include 4x8 feet, 4x10 feet, and 5x10 feet. Additionally, steel sheets are also available in various thicknesses ranging from gauge 10 to gauge 30.

- Q: What are the advantages of using galvanized steel sheets?

- Using galvanized steel sheets in various applications offers several advantages. Firstly, they exhibit high resistance to corrosion. The process of galvanizing involves applying a zinc layer to the steel sheets, which acts as a protective barrier against rust and other forms of corrosion. This makes galvanized steel sheets ideal for outdoor applications or environments that are prone to moisture, like construction sites or coastal areas. Secondly, galvanized steel sheets possess excellent durability and longevity. The zinc coating enhances their overall strength and resistance to wear and tear. Consequently, galvanized steel sheets can withstand heavy loads, extreme temperatures, and other harsh conditions, making them suitable for long-term use. Moreover, galvanized steel sheets prove to be cost-effective. Though the initial cost may be slightly higher compared to other materials, their long lifespan and low maintenance requirements offset this investment. Galvanized steel sheets do not require frequent painting or sealing, saving both time and money in the long run. Furthermore, galvanized steel sheets are environmentally friendly. The zinc coating used in the galvanizing process is recyclable, contributing to sustainable practices. Additionally, the extended lifespan of galvanized steel sheets reduces the need for frequent replacements, minimizing waste and conserving resources. Lastly, galvanized steel sheets offer versatility in terms of applications. They can be easily formed, shaped, and cut to meet specific requirements, making them suitable for a wide range of industries, including construction, automotive, and manufacturing. The ability to customize galvanized steel sheets ensures their compatibility with various designs and structural needs. In conclusion, the benefits of using galvanized steel sheets encompass superior corrosion resistance, durability, cost-effectiveness, environmental friendliness, and versatility. These advantages make galvanized steel sheets a favored choice across numerous industries and applications.

- Q: Are the steel sheets easy to transport and handle?

- Yes, steel sheets are relatively easy to transport and handle. They are typically lightweight and can be easily stacked and loaded onto trucks or containers for transportation. Additionally, steel sheets often come in standardized sizes and shapes, making them easier to handle and maneuver. However, it is important to note that the size and thickness of the steel sheets can impact the ease of transportation and handling. Larger and thicker sheets may require specialized equipment or additional manpower to lift and move.

- Q: What are the common thicknesses for hot-rolled steel sheets?

- The common thicknesses for hot-rolled steel sheets range from 1.6mm to 20mm, with some variations depending on specific industry requirements and applications.

- Q: Can steel sheets be used for electrical conductivity applications?

- No, steel sheets are not typically used for electrical conductivity applications. While steel is a good conductor of heat and has some electrical conductivity, it is not as efficient as other materials specifically designed for electrical conductivity, such as copper or aluminum. Steel sheets are commonly used in applications where strength, durability, and corrosion resistance are important, such as construction, automotive manufacturing, and industrial equipment. For electrical conductivity applications, it is more common to use materials with higher conductivity, such as copper or aluminum. These materials have lower resistance and are better suited for conducting electricity efficiently.

- Q: What are the different sheet metal welding techniques for steel sheets?

- There are several sheet metal welding techniques commonly used for steel sheets, including spot welding, seam welding, and TIG welding. Spot welding involves joining two metal sheets by applying pressure and heat at specific points, creating a strong bond. Seam welding, on the other hand, involves continuously welding along the length of a joint, creating a continuous welded seam. TIG welding, also known as tungsten inert gas welding, uses a non-consumable tungsten electrode to create an arc that melts the metal, forming a weld pool that fuses the steel sheets together. Each technique has its own advantages and is chosen based on the specific requirements of the project.

- Q: How do steel sheets handle electromagnetic interference?

- Steel sheets are highly effective in handling electromagnetic interference (EMI) due to their inherent electrical conductivity and magnetic permeability. These properties allow steel sheets to act as a shield against electromagnetic waves and prevent their penetration into or out of an enclosed space. When exposed to EMI, steel sheets act as a barrier, reflecting and absorbing electromagnetic waves, thus minimizing their impact on electronic devices and systems. This shielding effect is particularly crucial in sensitive environments such as data centers, laboratories, or industrial facilities where electromagnetic interference can disrupt electronic equipment and compromise their functionality. The thickness and composition of the steel sheet also play a significant role in determining its effectiveness in handling EMI. Thicker sheets provide better shielding due to increased attenuation of electromagnetic waves. Additionally, certain types of steel alloys, such as carbon steel or stainless steel, offer enhanced EMI shielding capabilities. It is important to note that while steel sheets provide excellent EMI shielding, they are not entirely impervious to electromagnetic waves. Factors such as the frequency of the waves and the size of any openings or gaps in the steel sheet can affect their shielding effectiveness. Therefore, proper installation and grounding techniques are essential to ensure optimal EMI protection. Overall, steel sheets are a reliable choice for managing electromagnetic interference, making them a preferred material in various industries where EMI shielding is critical for the uninterrupted operation of electronic devices and systems.

- Q: How do steel sheets compare to other materials like aluminum or stainless steel?

- When considering materials for use in various applications, steel sheets stand out as a superior choice when compared to alternatives like aluminum or stainless steel. One of their primary advantages lies in their immense strength and durability, surpassing both aluminum and stainless steel sheets. This makes them highly desirable for applications that necessitate robustness and resistance to wear and tear. Furthermore, steel sheets offer a significant cost advantage over stainless steel sheets. The production and acquisition costs associated with steel are generally lower, rendering it a more economically viable option for numerous industries. Additionally, the recyclability of steel sheets further contributes to their affordability and reduced environmental impact. On the other hand, aluminum sheets possess a distinct advantage in terms of weight. They are notably lighter than steel sheets, making them particularly beneficial in applications where weight is a concern, such as in the aerospace sector. Moreover, aluminum exhibits a natural resistance to corrosion, making it an excellent choice for outdoor applications or environments with high humidity levels. In contrast, stainless steel sheets excel in their resistance to corrosion and staining. This makes them a perfect fit for applications where hygiene and aesthetics hold paramount importance, such as in the food and medical industries. Furthermore, stainless steel sheets display exceptional heat resistance properties, rendering them suitable for high-temperature applications. In conclusion, steel sheets offer unmatched strength and durability when compared to aluminum or stainless steel sheets, all while maintaining a more cost-effective profile. However, it is important to acknowledge that both aluminum and stainless steel sheets possess unique properties that make them well-suited for specific applications. Ultimately, the selection between these materials hinges upon the specific requirements and limitations imposed by the project or industry at hand.

- Q: What are the different packaging options available for steel sheets?

- There are several packaging options available for steel sheets, including wooden crates, pallets, coils, and bundles. Wooden crates provide sturdy protection and are commonly used for transporting large steel sheets. Pallets are commonly used for smaller steel sheets and can be easily loaded and unloaded using a forklift. Coils are another option, where the steel sheet is wound into a coil shape for easier handling and transportation. Bundles involve securing multiple steel sheets together using metal bands or straps, providing a compact and secure packaging solution.

Send your message to us

CORRIGATED SHEET

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

Similar products

Hot products

Hot Searches

Related keywords