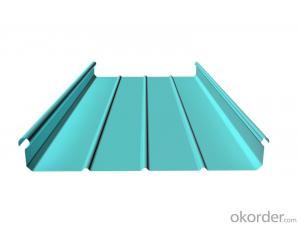

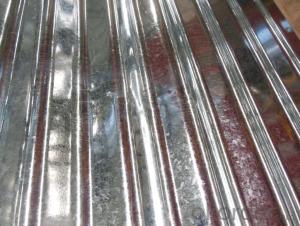

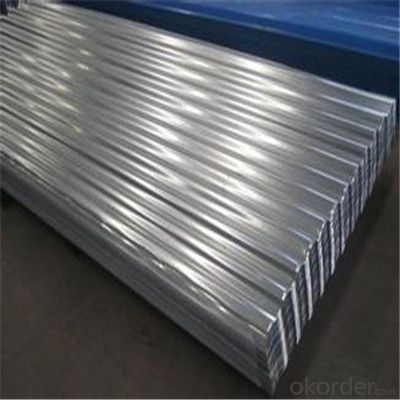

Galvanized Corrugated Iron Sheet for Roofing

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m.t.

- Supply Capability:

- 1000000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Description of Corrugated Iron Sheet:

1.Grade:SGCC, DX51D+Z, DX52D+Z, etc

2.Application:automotive, Strengthen plate, bearing

Specifications of Corrugated Iron Sheet:

| Product Name | Wave Tile |

| Standard: | GB , ASTM , JIS etc |

| Raw Material | GI , GL , PPGI , PPGL |

| Thickness | 0.15mm-0.6mm |

| Width | 750mm-1000mm(BC)/665-920mm(AC) |

| Length | 4000mm(Max) |

| Coating | AZ40-AZ160g , Z50-Z140g |

| Temper | Full hard , half hard , annealed |

| Spangle | Regular , Minimized , Big spangle |

| Pallet Weight: | 2-4mt |

| Material | SGCH , SGLCH , SGCC |

| Payment: | Trade Assurance OF Alibaba ,T/T, L/C at sight |

| MOQ: | 20 ton each size, 1x20'ft per delivery |

Features of Corrugated Iron Sheet:

Long Lasting

Strong & Light Weight

Better Corrosion Resistance

Better Thermal Efficiency

Aesthetically Pleasing

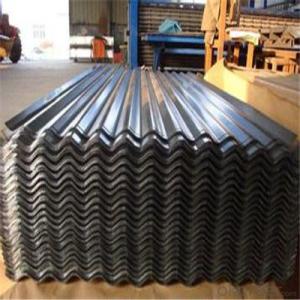

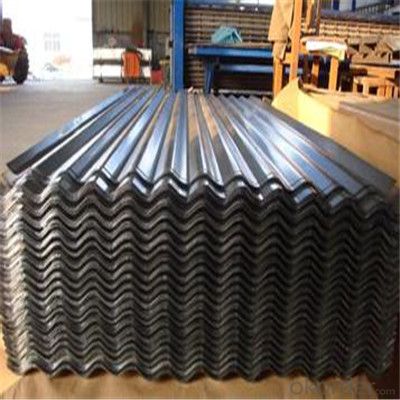

Images of Corrugated Iron Sheet:

FAQ:

1. What's the Delivery port?

The main ports are Qingdao and Tianjin, we also can deliver to other ports to meet your requirements

2. How long is the lead time?

Delivery time: 45 days after order confirmed.

3. What payment term do you accept?

Payment: T/T or L/C at sight.

- Q: Are steel sheets suitable for building envelopes or curtain walls?

- Yes, steel sheets are suitable for building envelopes or curtain walls. Steel is a versatile and durable material that offers structural strength and can withstand various weather conditions. Additionally, steel sheets can be easily fabricated and customized to meet specific design requirements, making them a popular choice for constructing building envelopes and curtain walls.

- Q: Are steel sheets resistant to vibrations?

- Yes, steel sheets are generally resistant to vibrations due to their high stiffness and strength properties.

- Q: Are steel sheets resistant to staining?

- Yes, steel sheets are generally resistant to staining due to their smooth and non-porous surface, making them less likely to absorb liquids or develop stains.

- Q: What is the average cost of installing steel sheets?

- The average cost of installing steel sheets can vary depending on various factors such as the size of the project, the type and quality of the steel sheets, the location, and the labor costs. On average, the cost of installing steel sheets can range from $7 to $15 per square foot. However, it is important to note that this is just a rough estimate and actual costs may vary significantly. It is recommended to obtain quotes from multiple contractors or steel suppliers to get a more accurate estimate for a specific project.

- Q: Can steel sheets be used for bulletproof applications?

- Yes, steel sheets can be used for bulletproof applications. Steel is a strong and durable material that can effectively stop bullets from penetrating through it. Bulletproof steel sheets are often used in the manufacturing of armored vehicles, military equipment, and personal protective gear such as bulletproof vests and helmets. The thickness and quality of the steel sheets play a crucial role in determining their bulletproof capabilities. Steel sheets can be designed to withstand different levels of ballistic protection, ranging from handguns to high-powered rifles. Additionally, steel's affordability and ease of production make it a popular choice for bulletproof applications in various industries.

- Q: What is the typical lifespan of painted steel sheets?

- The typical lifespan of painted steel sheets can vary depending on various factors such as the quality of the paint, the environment in which they are exposed, and the maintenance provided. However, on average, painted steel sheets can last anywhere from 20 to 30 years before they may require repainting or replacement.

- Q: Can steel sheets be used for acoustic insulation?

- Steel sheets can be used for acoustic insulation to some extent, but they are not as effective as other materials specifically designed for this purpose. Steel sheets have some natural sound-blocking properties due to their density and mass, which can help reduce the transmission of sound waves. However, they are not as effective as materials like mineral wool, fiberglass, or acoustic foam, which are specifically engineered to absorb and dampen sound. While steel sheets can provide a certain level of noise reduction, they are more commonly used for structural purposes in buildings rather than as primary acoustic insulation material. For optimal acoustic insulation, it is recommended to use materials that have been specifically designed and tested for noise reduction, as they will offer better performance in terms of absorbing and blocking sound waves.

- Q: Do the steel sheets come in different finishes?

- Yes, steel sheets come in different finishes such as polished, brushed, matte, and textured, among others.

- Q: Are the steel sheets suitable for water tank fabrication?

- Steel sheets are indeed appropriate for the fabrication of water tanks. Due to their strength and durability, steel can tolerate the pressure exerted by water and offer vital structural reinforcement. Moreover, when adequately coated or treated, steel proves resistant to corrosion, thereby guaranteeing the purity and unspoiled nature of the stored water. Additionally, steel sheets are highly malleable and can be effortlessly shaped and molded to meet precise design specifications for water tanks. Consequently, steel sheets emerge as a dependable and widely employed material choice for the construction of water tanks.

- Q: Are steel sheets prone to warping or buckling?

- Yes, steel sheets are prone to warping or buckling under certain conditions.

Send your message to us

Galvanized Corrugated Iron Sheet for Roofing

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m.t.

- Supply Capability:

- 1000000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords