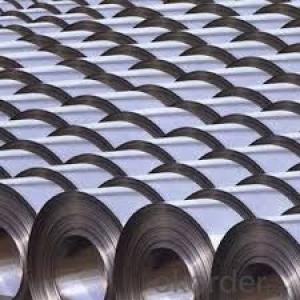

Hot Rolled Steel Coil /Cold Rolled Steel Coil

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m.t.

- Supply Capability:

- 6000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Hot rolled coils/plates

Type: steel coil and steel plates

Material: SS400-Q235-Q345-SPHC

Width:1250mm 1500mm 1800mm 2000mm

HOT-ROLLED COIL/PLATES(Material: SS400-Q235A/B-SPHC) | |||

2.00*1250/1500L | 3.50*1250/1500L | 5.75*1250/1500L | 11.50*1250/1500L |

2.30*1250/1500L | 3.75*1250/1500L | 7.50*1250/1500L | 11.75*1250/1500L |

2.50*1250/1500L | 4.50*1250/1500L | 7.75*1250/1500L | 13.50*1250/1500L |

2.75*1250/1500L | 4.75*1250/1500L | 9.50*1250/1500L | |

3.00*1250/1500L | 5.50*1250/1500L | 9.75*1250/1500L | |

PATTERN-ROLLED COIL/PLATES(Material: Q235A-Q235B) | |||

3.00*1250L | 3.75*1250L | 4.75*1250L | 5.75*1250L |

3.50*1250L | 4.50*1250L | 5.50*1250L | 7.50*1250L |

MIDDEL-PLATE(Material: Q235A/B-Q345A/B) | |||

8*1800/2000L | 16*1800/2000L | 25*1800/2000L | 45*1800/2000L |

10*1800/2000L | 18*1800/2000L | 30*1800/2000L | 50*1800/2000L |

12*1800/2000L | 20*1800/2000L | 35*1800/2000L | |

14*1800/2000L | 221800/2000L | 401800/2000L | |

Name | galvanized steel coil dx52d z gi |

Grade | GB/T-12754: 2006, JIS3302, EN 10142, ASTM A653, JIS G3302, SGCC/SGCH, GB/T2518, European Standard, ASTM A792, JIS G3321, JIS G3317 |

BASE PLATE | Cold rolled steel sheet, hot dipped zinc coated steel sheet hot dipped A-Z coated steel sheet |

EQUIPMENT | Double coating double baking; |

CAPACITY | 5000Mt/week |

SIZE | Thickness 0.18mm—2mm, width 40mm—1250mm |

ZINC COATING | 40g-275g /m2 |

PAINT THICKNESS | Top:20+-5um, back:5-7um |

COIL WGT | 3Mt - 8Mt |

COIL ID | φ508mm,φ610mm |

BASE SHEET | Cold rolled steel sheet, hot dipped zinc coated steel sheet (small, regular or zero spangle), hot dipped A-Z coated steel sheet |

SURFACE PAINT | EP, PE, HDP, SMP, PVDF |

COLOR SERIES | RAL color number series |

Applications of cold rolled steel sheet coil :

1) Automotive bodies: filters, fuel tanks, etc.

2) Construction materials: roofings, welding pipes,

3) Electric and electronic appliances: computer cans, etc.

4) Steel cans: containers, etc.

5) Steel furniture: washing machines, refrigerators, microwaves, etc.

6) Drums

7) Office equipment: printer, recorders, etc.

8) Motors and transformers

Process of cold rolled steel sheet coil :

Pay off reel-double cut shear-welder-notcher-entry accumulator-pre cleaning section-furnace-hot bridle-zinc pot-air knife-after cooler-water quench-dryer- skin pass mill-dryer-tension leveler-dryer-chemical coater-chemical oven-cooler-exit accumulator-oiler-exit shear-tension reel.

Features of cold rolled steel sheet coil :

1) cold rolled steel coils prices is manufactured to have a long durability, strong corrosion resistance and shiny surface.

2) cold rolled steel coils prices features excellent forming properties, paintability, weldability, and is suitable for fabrication by forming, pressing and bending.

Q&A Acceptable payment term and way ?

ANSWER: T/T,L/C, T/T + L/C, D/P

Q&A Do you accept OA payment terms?

ANSWER: Yes, sure, but it normally depending on the order value

Q&A Do you have QC team?

ANSWER: Yeah, sure, our QC team is very important, they will keep the quality control for our products.

- Q: What is the weight of each steel sheet?

- The weight of each steel sheet depends on its dimensions and thickness. Steel sheets come in various sizes and thicknesses, so the weight can vary. To determine the weight, you would need to know the length, width, and thickness of the steel sheet. Once you have these measurements, you can use a weight calculator or reference a steel weight chart to find the weight per square meter or per square foot of the steel sheet. Multiplying this weight by the surface area of the sheet will give you the total weight of each steel sheet.

- Q: Can steel sheets be used for roofing?

- Yes, steel sheets can be used for roofing. Steel is a durable and long-lasting material that provides excellent protection against weather elements, making it a popular choice for roofing applications.

- Q: What is the thickness of the steel sheets?

- The thickness of steel sheets may vary depending on the specific application and requirements. Steel sheets can have thicknesses ranging from 0.4 millimeters to several inches, and commonly used measurements include 0.5 mm, 1.0 mm, 1.5 mm, 2.0 mm, 2.5 mm, and so on. However, it is worth noting that the thickness can be tailored to suit the intended use, such as in construction, manufacturing, or automotive industries. Therefore, it is crucial to refer to the specifications or contact the manufacturer or supplier to ascertain the precise thickness of the steel sheets in question.

- Q: Are the steel sheets suitable for solar panel mounting?

- Yes, steel sheets are suitable for solar panel mounting. They provide strong support and durability, making them an ideal choice for securely mounting solar panels on various surfaces.

- Q: What are the different quality standards for steel sheets?

- There are several different quality standards for steel sheets, including ASTM (American Society for Testing and Materials), AISI (American Iron and Steel Institute), JIS (Japanese Industrial Standards), and EN (European Norms). These standards outline specific requirements for various aspects of steel sheets, such as chemical composition, mechanical properties, dimensional tolerances, and surface finish. Compliance with these standards ensures that steel sheets meet certain quality and performance criteria and can be used for specific applications in various industries.

- Q: Why should the back of the steel sheet pile cofferdam be pumped after the construction of the pile cap?

- Loading and unloading steel sheet piles should be operated by two points lifting method. The number of steel pile piles should not be too many at any time, and attention should be paid to the protection of the locking hole to avoid damage.

- Q: Are steel sheets suitable for cold storage applications?

- Yes, steel sheets are suitable for cold storage applications. Steel is a durable and strong material that can withstand the low temperatures typically required for cold storage. It is resistant to corrosion and does not absorb moisture, making it ideal for keeping the cold air inside the storage area. Additionally, steel sheets can be easily cleaned and sanitized, which is important in maintaining the hygiene and safety of the stored items. Steel also provides excellent insulation properties, helping to maintain a consistent temperature within the cold storage facility. Furthermore, steel sheets can be customized and fabricated to meet the specific size and shape requirements of the cold storage application. Overall, steel sheets are a reliable and practical choice for cold storage applications.

- Q: What are the different types of steel sheet coatings?

- There are several different types of steel sheet coatings, including galvanized coatings, tin coatings, and polymer coatings.

- Q: Do steel sheets require any special storage or handling?

- Yes, steel sheets do require special storage and handling. Steel sheets are prone to corrosion and damage, so it is important to store them in a dry and well-ventilated area to prevent moisture buildup. They should be kept away from direct sunlight and extreme temperature fluctuations, as this can cause warping or cracking. Steel sheets should be stored horizontally on a flat surface to prevent bending or sagging. It is also recommended to stack them properly and securely, using appropriate supports or pallets, to avoid any accidents or injuries. When handling steel sheets, it is important to use proper lifting equipment and techniques to prevent injuries and avoid damaging the sheets. Gloves should be worn to protect against sharp edges, and care should be taken to prevent any contact with other materials that may cause scratches or damage. Overall, following these storage and handling guidelines will help ensure the longevity and quality of steel sheets.

- Q: What is the weight of each steel sheet?

- The weight of each steel sheet depends on its dimensions and thickness, as steel comes in various sizes and densities.

Send your message to us

Hot Rolled Steel Coil /Cold Rolled Steel Coil

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m.t.

- Supply Capability:

- 6000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords