Galvanized Corrugated Iron Sheet for Roofing Type

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m.t.

- Supply Capability:

- 1000345 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Description of Corrugated Iron Sheet:

Smart appearance with subtle square fluting

Anti-capillary groove ensures leak-proof roof

Minimum yield strength of 550 MPa ensures required strength for roofing application

Accurate thickness, width and length gives a perfect fit for any roof

Wider valley ensures higher water discharge in case of heavy rains

Specifications of Corrugated Iron Sheet:

| Product Name | Wave Tile |

| Standard: | GB , ASTM , JIS etc |

| Raw Material | GI , GL , PPGI , PPGL |

| Thickness | 0.15mm-0.6mm |

| Width | 750mm-1000mm(BC)/665-920mm(AC) |

| Length | 4000mm(Max) |

| Coating | AZ40-AZ160g , Z50-Z140g |

| Temper | Full hard , half hard , annealed |

| Spangle | Regular , Minimized , Big spangle |

| Pallet Weight: | 2-4mt |

| Material | SGCH , SGLCH , SGCC |

| Payment: | Trade Assurance OF Alibaba ,T/T, L/C at sight |

| MOQ: | 20 ton each size, 1x20'ft per delivery |

Features of Corrugated Iron Sheet:

Raw material width 762mm, after corrugated width 665mm: 9 waves.

Raw material width 914mm ,after corrugated width 800mm:11 waves.

Raw material width 1000mm, after corrugated 890mm or 900mm :12 or 14 waves. as customer requirement

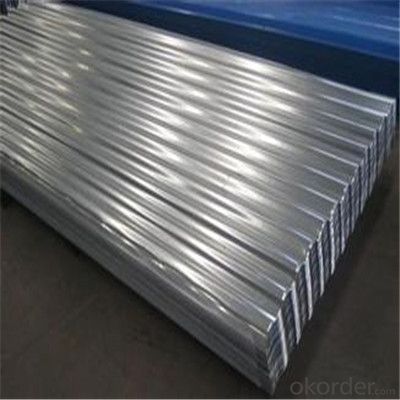

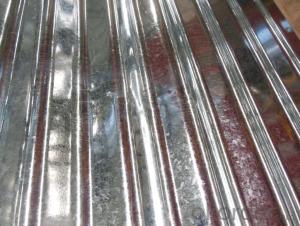

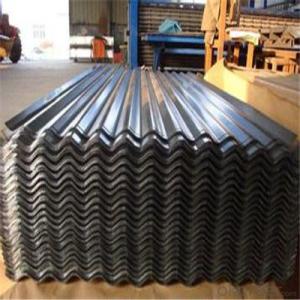

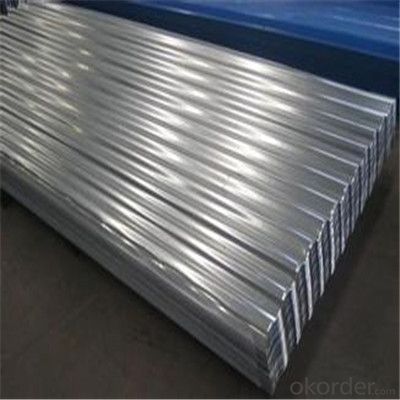

Images of Corrugated Iron Sheet:

FAQ:

1. What's the Delivery port?

The main ports are Qingdao and Tianjin, we also can deliver to other ports to meet your requirements

2. How long is the lead time?

Delivery time: 45 days after order confirmed.

3. What payment term do you accept?

Payment: T/T or L/C at sight.

- Q: Are steel sheets suitable for high-pressure applications?

- Yes, steel sheets are suitable for high-pressure applications. Steel is known for its strength, durability, and resistance to deformation, making it an ideal material for withstanding high pressures.

- Q: Will the plating steel be rusty? Will it rust when touching the water?

- Galvanized steel plate as long as the plating is good, the surface coating does not fall off, will not rust, often see electroplating parts rust, because the coating is formed.

- Q: Can steel sheets be used in corrosive environments like saltwater?

- Steel sheets can be used in corrosive environments like saltwater, but they need to be properly protected through methods such as coating or galvanization to prevent corrosion.

- Q: Can steel sheets be used for structural purposes?

- Yes, steel sheets can be used for structural purposes. Steel sheets are commonly used in construction and engineering projects to provide strength and support to various structures such as buildings, bridges, and infrastructure. The high tensile strength and durability of steel make it an ideal material for structural applications.

- Q: What are the weight and load-bearing capacities of steel sheets?

- The weight and load-bearing capacities of steel sheets can vary depending on the specific grade and thickness of the sheet. However, steel sheets are known for their high strength and durability, making them capable of supporting heavy loads. It is best to consult the manufacturer or reference technical specifications for accurate weight and load-bearing capacity information for a particular steel sheet.

- Q: Can steel sheets be used for kitchen backsplashes?

- Kitchen backsplashes can indeed utilize steel sheets. Steel is a highly versatile and enduring material that can withstand the demands of a kitchen setting. It possesses resistance against heat, moisture, and stains, rendering it an ideal selection for a kitchen backsplash. Moreover, steel backsplashes are effortless to clean and maintain, as they can be easily wiped down using a damp cloth or gentle cleaning solution. Steel sheets also contribute to a sleek and contemporary appearance, lending a touch of elegance to any kitchen design. However, it is important to mention that steel is susceptible to scratching. Hence, it is advisable to opt for a stainless steel variation, which offers enhanced resistance against scratches. All in all, steel sheets present a practical and stylish alternative for kitchen backsplashes.

- Q: How thick are steel sheets typically?

- Steel sheets can vary in thickness depending on their intended use, but they are typically available in a range of thicknesses starting from 0.4 millimeters (0.0157 inches) and can go up to several millimeters.

- Q: What are the different types of steel sheet finishes?

- Various purposes are served by several different types of steel sheet finishes, each providing unique aesthetics. Some common types include: 1. Hot Rolled: Achieved by heating the steel sheet above its recrystallization temperature and rolling it to the desired thickness. It has a rough and textured surface, suitable for applications where appearance is not a priority. 2. Cold Rolled: After hot rolling, the steel sheet is passed through rollers at room temperature to achieve a smooth and polished finish. Cold rolled finishes are often used in applications that require a superior surface finish, such as automotive panels or appliances. 3. Galvanized: In this process, the steel sheet is coated with a layer of zinc to provide corrosion resistance. The zinc coating also gives the sheet a shiny and reflective appearance. Galvanized finishes are commonly used in outdoor applications to protect against rust and harsh weather conditions. 4. Stainless Steel: Achieved by adding chromium to the steel sheet, providing excellent corrosion resistance and a sleek, reflective surface. Stainless steel finishes are widely used in kitchen appliances, architectural applications, and medical equipment, where hygiene and durability are essential. 5. Coated Finishes: Steel sheets can be coated with various materials, like paint, epoxy, or polymer, to enhance appearance or provide additional protection. Coated finishes can be customized to meet specific requirements, such as color or texture, and are often used in architectural and decorative applications. 6. Brushed: Obtained by brushing the steel sheet with abrasive material, creating a textured and matte surface. Brushed finishes are commonly used in interior design and furniture manufacturing, where a contemporary and stylish appearance is desired. These examples represent just a few of the available steel sheet finishes. The choice of finish depends on the specific requirements of the application, such as corrosion resistance, aesthetic appeal, or surface texture.

- Q: How do you store steel sheets to prevent damage?

- To prevent damage to steel sheets, it is recommended to store them in a dry, well-ventilated area, away from moisture or humidity. They should be stored horizontally on a flat surface, with adequate support to prevent bending or warping. Additionally, using protective covers or separators between each sheet can help prevent scratches or surface damage.

- Q: Can steel sheets be used for insulation in buildings?

- No, steel sheets cannot be used as insulation in buildings. Steel is a highly conductive material, meaning it allows heat to pass through it easily. Insulation, on the other hand, is designed to resist the flow of heat, keeping the interior of a building warm in winter and cool in summer. Materials such as fiberglass, foam, or cellulose are commonly used for insulation as they have low thermal conductivity.

Send your message to us

Galvanized Corrugated Iron Sheet for Roofing Type

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m.t.

- Supply Capability:

- 1000345 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords