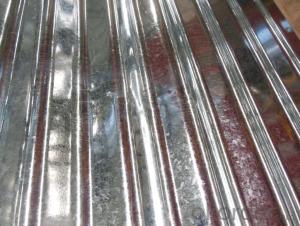

Galvanised Steel sheets

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Description:

Product Description:

Hot Dipped Galvanized Steel Coil

Hot-dip galvanized steel coils are available with a pure zinc coating through the hot-dip galvanizing process. It offers the economy, strength and formability of steel combined with the corrosion resistance of zinc. The hot-dip process is the process by which steel gets coated in layers of zinc to protect against rust. It is especially useful for countless outdoor and industrial applications.

Product Description Of Hot Dipped Galvanized Steel Coil

Thickness | 0.13mm-0.7mm |

Width | 600mm-1250mm |

Zinc Coating | 30-200g/m2 |

Internal Diameter | 508mm/610mm |

Coil Weight | 3-12MT |

Quality | commercial and structural quality |

Surface Treatment | regular & minimum spangle, zero spangle, oiled & dry, chromated , non-skin pass , skin pass |

Standard | JIS G 3302, ASTM A 653M, EN 10327 |

Steel Grade | SGCC, CS, FS, SS, LFQ, DX51D+Z , S280GD |

Technical Data Of Hot Dipped Galvanized Steel Coil

Chemical Composition | C | Si | Mn | P | S |

0.04-0.06% | 0.01-0.03% | 0.18-0.22% | 0.014-0.016% | 0.006%-0.009% |

Yield Strength | (Mpa) 280-320 |

Tensile Strength | (Mpa) 340-390 |

Elongation | 20%-30% |

Out-of-square | not exceed 1% Flatness |

Bow | 15mmmax |

Edge Wave | 9mmmax |

Centre Buckle | 8mmmax |

Bending At 180 Degree | No crack, purling and fraction |

Application Of Hot Dipped Galvanized Steel Coil

It can be widely used in transportation, light industry, civil usage and farming. It is also the perfect building material in construction for making roofing tile, steel profiles for wall partition, T-bar, studs, fireproof door, air conditioning duct and home appliance.

- Q: Are steel sheets prone to warping or bending over time?

- In general, warping or bending over time is not a common issue with steel sheets. Steel is renowned for its exceptional strength and durability, making it less prone to deformation compared to alternative materials. It is worth noting, however, that the thickness and quality of the steel sheet can impact its susceptibility to warping or bending. Thicker and higher-quality steel sheets have a lower likelihood of warping or bending. Furthermore, implementing appropriate installation and maintenance techniques can also help prevent warping or bending of steel sheets. All in all, steel sheets are widely regarded as a dependable and steadfast material that maintains its shape and integrity throughout time.

- Q: Are the steel sheets heat-resistant?

- Yes, steel sheets are heat-resistant. Steel is known for its high melting point, which makes it a suitable material for applications that involve exposure to high temperatures. It can withstand heat without warping or losing its structural integrity. However, the exact level of heat resistance may vary depending on the specific type of steel and its composition. Some steel alloys are specifically designed to have even higher heat resistance, making them suitable for use in industries such as aerospace, automotive, and construction, where high-temperature environments are common.

- Q: Can steel sheets withstand extreme temperatures?

- Indeed, extreme temperatures pose no challenge to steel sheets. Renowned for its remarkable melting point of approximately 1370°C (2500°F), steel proves itself as an ideal choice for environments characterized by intense heat, including furnaces, kilns, and industrial ovens. Moreover, steel exhibits exceptional thermal conductivity, enabling efficient heat transfer while effectively withstanding the expansion and contraction caused by temperature fluctuations. Thanks to these exceptional attributes, steel sheets remain impervious to warping, cracking, and other structural impairments often encountered in extreme temperature scenarios.

- Q: What is the difference between zinc-coated and zinc-aluminum coated steel sheets?

- Zinc-coated and zinc-aluminum coated steel sheets are two types of steel that have undergone zinc treatment for protection. However, there are differences between the two processes that result in varying characteristics and performance. Galvanized steel sheets, also known as zinc-coated steel sheets, are made by immersing the steel sheets in molten zinc. This creates a layer of pure zinc on the steel's surface, forming a barrier against corrosion. The zinc layer is typically evenly applied across the entire sheet. On the other hand, galvalume or Aluzinc steel sheets, which are zinc-aluminum coated, are created by coating the steel sheets with a mixture of zinc and aluminum. This coating is applied using a hot-dip process, similar to the one used for zinc-coated steel sheets. The aluminum in the coating enhances corrosion resistance compared to pure zinc coatings. The main difference between zinc-coated and zinc-aluminum coated steel sheets lies in their performance and durability. Zinc-coated sheets effectively protect against corrosion in most atmospheric environments. However, in more aggressive or severe environments, such as high humidity or exposure to saltwater, zinc-coated steel may not provide sufficient protection and can corrode over time. In contrast, zinc-aluminum coated steel sheets offer superior corrosion resistance due to the presence of aluminum in the coating. The aluminum acts as a sacrificial anode, corroding preferentially to the steel and safeguarding it from corrosion. This makes zinc-aluminum coated sheets more suitable for environments with significant corrosion concerns, such as coastal areas or industrial settings. In conclusion, while both zinc-coated and zinc-aluminum coated steel sheets provide a protective zinc layer, zinc-aluminum coated sheets offer improved corrosion resistance due to the inclusion of aluminum. Therefore, zinc-aluminum coated steel sheets are generally preferred in aggressive or corrosive environments, while zinc-coated steel sheets are suitable for most atmospheric conditions.

- Q: What is the difference between a smooth and expanded metal steel sheet?

- A smooth steel sheet is characterized by its flat surface devoid of any visible patterns or perforations. It finds its typical usage in situations where a sleek aesthetic is desired, such as architectural or decorative purposes. Countertops, backsplashes, and wall coverings often make use of smooth steel sheets. On the contrary, an expanded metal steel sheet is fashioned by cutting and stretching a solid steel sheet, resulting in a pattern of interconnected diamond-shaped openings. This process not only enhances the sheet's structural integrity but also allows for increased airflow, visibility, and drainage. Industrial and construction applications, including walkways, grating, fencing, and machine guards, commonly employ expanded metal steel sheets. The primary dissimilarity between smooth and expanded metal steel sheets lies in their appearance, functionality, and intended applications. Smooth steel sheets offer a polished and pristine appearance, while expanded metal steel sheets provide strength, ventilation, and versatility. Ultimately, the choice between the two hinges on the specific requirements of the project at hand.

- Q: Are the steel sheets suitable for agricultural applications?

- Yes, steel sheets are suitable for agricultural applications. Steel is a versatile and durable material that can withstand harsh weather conditions and provide long-term structural support. Steel sheets can be used in various agricultural applications such as constructing farm buildings, barns, sheds, and storage facilities. They can also be used for fencing, roofing, and siding purposes. Steel sheets offer excellent strength and resistance to pests, fire, and rot, making them ideal for protecting agricultural equipment and crops. Additionally, steel is recyclable, which makes it an environmentally-friendly choice for sustainable farming practices. Overall, steel sheets are a reliable and cost-effective solution for various agricultural applications.

- Q: How do steel sheets perform in electrical resistance?

- Steel sheets are not good conductors of electricity and have relatively high electrical resistance compared to other materials such as copper or aluminum.

- Q: What are the different bending radius options for steel sheets?

- The bending radius options for steel sheets can vary depending on the thickness and type of steel being used. However, common bending radius options for steel sheets typically range from 0.5 times the thickness of the sheet to 2 times the thickness of the sheet.

- Q: Can steel sheets be used for food processing or storage?

- No, steel sheets should not be used for food processing or storage. While steel is a durable and commonly used material in many industries, including food processing, it is not suitable for direct contact with food. Steel sheets may contain various chemicals, such as zinc coating or other metallic coatings, which can potentially contaminate the food and pose health risks. Additionally, steel sheets are prone to rusting, and the presence of rust can also contaminate the food. Therefore, it is recommended to use food-grade materials such as stainless steel or food-grade plastic for food processing and storage to ensure the safety and quality of the food.

- Q: What is the standard size of a steel sheet?

- The specific application and industry play a significant role in determining the varying standard sizes of steel sheets. However, it is common to find steel sheets in standard sizes like 4 feet by 8 feet (1.2 meters by 2.4 meters) or 5 feet by 10 feet (1.5 meters by 3 meters). These dimensions are widely utilized in construction, manufacturing, and fabrication processes. It is worth mentioning that customized sizes can be obtained to cater to the specific needs of a project or customer.

Send your message to us

Galvanised Steel sheets

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords