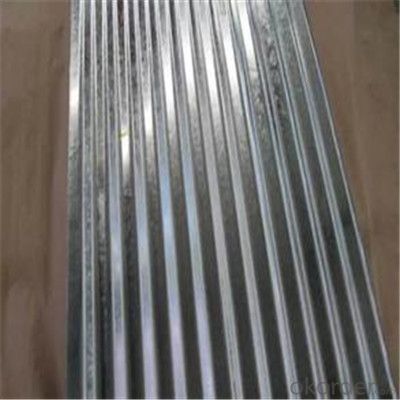

Galvanized Corrugated Iron Sheet for Roofing Type Galvanized Iron Plain Sheet

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m.t.

- Supply Capability:

- 1000000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Description of Corrugated Iron Sheet:

1.Grade:SGCC, DX51D+Z, DX52D+Z, etc

2.Application:automotive, Strengthen plate, bearing

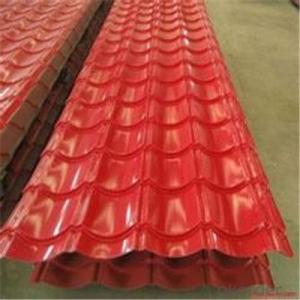

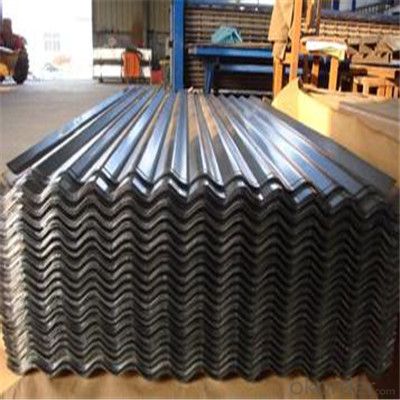

Specifications of Corrugated Iron Sheet:

| Product Name | Wave Tile |

| Standard: | GB , ASTM , JIS etc |

| Raw Material | GI , GL , PPGI , PPGL |

| Thickness | 0.15mm-0.6mm |

| Width | 750mm-1000mm(BC)/665-920mm(AC) |

| Length | 4000mm(Max) |

| Coating | AZ40-AZ160g , Z50-Z140g |

| Temper | Full hard , half hard , annealed |

| Spangle | Regular , Minimized , Big spangle |

| Pallet Weight: | 2-4mt |

| Material | SGCH , SGLCH , SGCC |

| Payment: | Trade Assurance OF Alibaba ,T/T, L/C at sight |

| MOQ: | 20 ton each size, 1x20'ft per delivery |

Features of Corrugated Iron Sheet:

Cold rolled steel coil-uncoil-Pickling-Annealed-hot dipped galvanizing-cooling -surface treatment -rolling -Cut the coil (galvanized steel sheet), demand your requirement. remark:Less than 5.8m ,20'container is ok,greater than5.8m,we must use 40'container

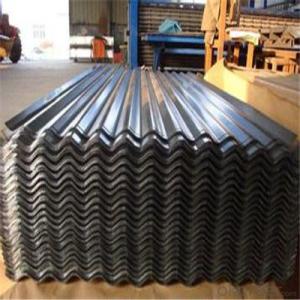

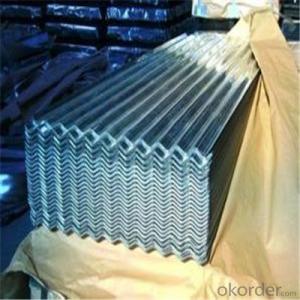

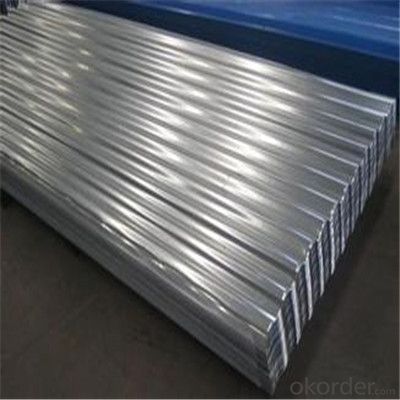

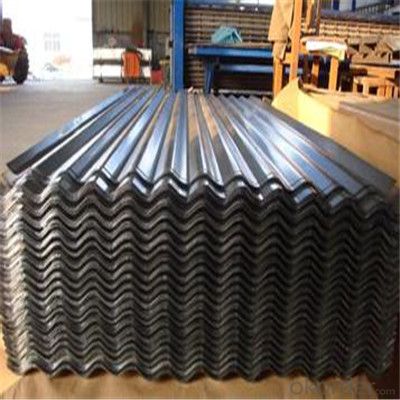

Images of Corrugated Iron Sheet:

FAQ:

1. What's the Delivery port?

The main ports are Qingdao and Tianjin, we also can deliver to other ports to meet your requirements

2. How long is the lead time?

Delivery time: 45 days after order confirmed.

3. What payment term do you accept?

Payment: T/T or L/C at sight.

- Q: Can steel sheets be used for construction formwork or molds?

- Certainly, construction formwork or molds can utilize steel sheets, although their usage may not be as prevalent as materials like plywood or timber. Robust and enduring, steel sheets offer a sleek and uniform surface for concrete casting. They prove especially fitting for expansive construction ventures demanding formwork capable of withstanding immense pressures and loads. Additionally, steel sheets can be tailor-made and manufactured to meet precise project specifications, affording versatility in terms of shape, size, and arrangement. Nevertheless, the cost, weight, and accessibility of steel sheets should be weighed against alternative formwork materials prior to reaching a verdict.

- Q: How to introduce carbon steel plate?

- Grade: the cases of Q235-A F, said the sigma s Note: Q is more than 235MPa grade yield strength of A grade (ABCD four), F boiling steel characteristics: low price, process performance (such as welding and excellent cold formability). Applications: general engineering structures and general mechanical parts. Such as Q235 can make bolts, nuts, pins, hooks and less important mechanical parts, as well as the construction of the thread steel, steel, steel and so on

- Q: Can steel sheets be used for solar panel mounting structures?

- Yes, steel sheets can be used for solar panel mounting structures. Steel is a commonly used material for solar panel mounts due to its strength, durability, and ability to withstand various weather conditions. Steel sheets can provide a sturdy and reliable support system for solar panels, ensuring their stability and longevity.

- Q: What is the process of applying insulation materials to steel sheets?

- The process of applying insulation materials to steel sheets typically involves preparing the steel surface, applying an adhesive or bonding agent, and then affixing the insulation material to the steel using pressure or other mechanical means. This ensures a secure and effective insulation layer on the steel sheets.

- Q: Are steel sheets resistant to radiation?

- No, steel sheets are not inherently resistant to radiation.

- Q: Are steel sheets prone to warping or buckling?

- Yes, steel sheets are prone to warping or buckling due to external factors such as heat, pressure, or improper handling.

- Q: What is the typical thickness tolerance for steel sheets?

- The steel sheet thickness tolerance can vary depending on the specific industry and application requirements. Different industries or applications may have more stringent tolerance requirements, especially when precision is crucial. In such cases, the tolerance may be tighter. Specialized steel products or specific customer requirements may also lead to different tolerance specifications. Manufacturers employ strict quality control measures to ensure compliance with the desired thickness tolerance. These measures include precise calibration of equipment, regular inspection of raw materials, and comprehensive testing procedures. This helps maintain the integrity and reliability of steel sheets for various applications in industries such as automotive, construction, manufacturing, and more.

- Q: What are the disadvantages of using steel sheets?

- Some potential disadvantages of using steel sheets are their susceptibility to corrosion, their relatively high cost compared to other materials, and their heavy weight, which can make installation and transportation more challenging. Additionally, steel sheets may require regular maintenance to prevent rust and may not be suitable for certain design aesthetics or applications where a lighter material is desired.

- Q: What are the applications of steel sheets in construction?

- Steel sheets have a wide range of applications in construction due to their exceptional strength, durability, and versatility. Some of the key applications of steel sheets in construction include: 1. Roofing and cladding: Steel sheets are commonly used for roofing and cladding in both residential and commercial buildings. They provide a weather-resistant and long-lasting solution, protecting the structure from the elements. 2. Structural components: Steel sheets are utilized in the construction of structural components like beams, columns, and trusses. The high strength-to-weight ratio of steel allows for the creation of lightweight yet robust structures that can withstand heavy loads and seismic forces. 3. Flooring: Steel sheets are often used as flooring material in industrial buildings, warehouses, and factories. Their smooth surface makes it easy to clean and maintain, while their strength and fire-resistant properties provide a safe working environment. 4. Wall partitions: Steel sheets are commonly employed in the construction of wall partitions due to their stability and sound insulation properties. They can easily be cut and shaped to fit any design, allowing for flexible and customizable partition layouts. 5. Ductwork and HVAC systems: Steel sheets are widely used in the fabrication of ductwork and HVAC systems. Their smooth and airtight surfaces allow for efficient air movement and regulation, ensuring proper ventilation and temperature control in buildings. 6. Reinforcement: Steel sheets are often integrated into concrete structures as reinforcement. This helps to enhance the strength and load-bearing capacity of the building, making it more resistant to bending, tension, and compression forces. 7. Safety and security: Steel sheets are utilized in the construction of safety and security features such as doors, gates, and window frames. Their high strength and resistance to impact and vandalism make them an ideal choice for ensuring the safety and protection of a building. In summary, steel sheets are extensively used in construction for roofing, cladding, structural components, flooring, wall partitions, ductwork, reinforcement, and safety features. Their superior strength, durability, and versatility make them an essential component in various construction applications, contributing to the overall safety, longevity, and functionality of buildings.

- Q: Are the steel sheets coated with any protective material?

- Yes, the steel sheets are coated with a protective material. The protective coating is typically applied to the steel sheets to enhance their durability and resistance to corrosion. This coating acts as a barrier between the steel surface and external elements such as moisture, chemicals, and weather conditions, preventing the steel from rusting or corroding. The protective material can vary depending on the specific application and requirements, but it is commonly a layer of zinc or zinc-alloy coating, known as galvanized coating. This coating provides excellent protection to the steel sheets and extends their lifespan, making them suitable for various industries and applications.

Send your message to us

Galvanized Corrugated Iron Sheet for Roofing Type Galvanized Iron Plain Sheet

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m.t.

- Supply Capability:

- 1000000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords