Galvanized Corrugated Iron Sheet for Roofing Type Galvanized Steel Plain Sheet

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 300 m.t.

- Supply Capability:

- 1000000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

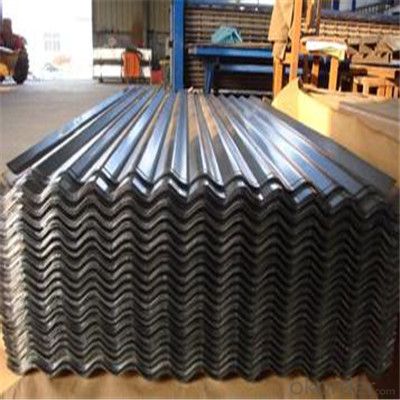

Description of Corrugated Iron Sheet:

Weight of each package: about 4.1mt

Width: 600mm-1250mmWidth tolerance:-0/+3mm

Depth of corrugated: from 23mm to 25mm

Pitch: from 57mm to 59mm

Length: less than 12m

Surface treatment: chromate, oil/unoil, bright finish, spangle

Specifications of Corrugated Iron Sheet:

| Product Name | Wave Tile |

| Standard: | GB , ASTM , JIS etc |

| Raw Material | GI , GL , PPGI , PPGL |

| Thickness | 0.15mm-0.6mm |

| Width | 750mm-1000mm(BC)/665-920mm(AC) |

| Length | 4000mm(Max) |

| Coating | AZ40-AZ160g , Z50-Z140g |

| Temper | Full hard , half hard , annealed |

| Spangle | Regular , Minimized , Big spangle |

| Pallet Weight: | 2-4mt |

| Material | SGCH , SGLCH , SGCC |

| Payment: | Trade Assurance OF Alibaba ,T/T, L/C at sight |

| MOQ: | 20 ton each size, 1x20'ft per delivery |

Features of Corrugated Iron Sheet:

(1) Novel and beautiful modeling , rich luster, strong adornment sex, flexible in combination, can express different architectural styles;

(2) Light weight (6 ~ 10 kg/m squared) high strength (yield strength 250 ~ 550 mpa) fine skin stiffness,fine seismic performance of waterproofing agent;

(3) Factory product with high quality

Images of Corrugated Iron Sheet:

FAQ:

1. What's the Delivery port?

The main ports are Qingdao and Tianjin, we also can deliver to other ports to meet your requirements

2. How long is the lead time?

Delivery time: 45 days after order confirmed.

3. What payment term do you accept?

Payment: T/T or L/C at sight.

- Q: How do steel sheets compare to other materials, such as aluminum or copper?

- Steel sheets have several advantages over other materials such as aluminum or copper. Steel is generally stronger and more durable, making it suitable for applications that require high strength and resistance to wear and tear. It is also more cost-effective and readily available, making it a popular choice in various industries. While aluminum and copper may offer better conductivity or corrosion resistance, steel sheets often provide a good balance of properties, making them a versatile and widely used material.

- Q: Are steel sheets suitable for high-vibration environments?

- Due to their inherent strength and durability, steel sheets are commonly used in high-vibration environments. Steel possesses excellent mechanical properties, such as high tensile strength and resistance to fatigue, making it capable of withstanding vibrations without significant deformation or failure. Additionally, steel sheets possess the ability to absorb and dissipate vibrations due to their mass and stiffness. This feature enables them to effectively reduce the transmission of vibrations to other components or structures. By absorbing and dissipating the energy generated by vibrations, steel sheets minimize the potential for damage or disruption. Moreover, steel sheets can be customized and produced to meet specific requirements for high-vibration environments. They can undergo reinforcement or be treated with coatings to enhance their resistance to corrosion, wear, and fatigue, thus further enhancing their suitability for such conditions. However, it is crucial to carefully consider the specific characteristics and intensity of the vibration environment when determining the compatibility of steel sheets. Factors such as frequency, amplitude, and duration of vibrations need to be taken into account. In extreme cases, alternative materials or specialized designs may be necessary to ensure optimal performance and longevity. In conclusion, steel sheets are generally well-suited for high-vibration environments due to their strength, durability, and vibration-dampening capabilities. Nonetheless, a comprehensive evaluation of the specific conditions is essential to determine the most appropriate solution for each application.

- Q: What are the tolerances for steel sheets?

- The tolerances for steel sheets typically depend on the specific industry and application. However, common tolerances for steel sheets are usually specified in terms of thickness, flatness, width, and length. These tolerances can vary but are typically within a few percentage points of the specified dimensions.

- Q: Can steel sheets be used for storage racks or shelves?

- Yes, steel sheets can be used for storage racks or shelves. Steel is a durable and strong material, making it ideal for heavy-duty storage applications. Steel sheets can be fabricated into various shapes and sizes to create storage racks or shelves that can hold heavy items and withstand the weight over time. Additionally, steel is resistant to corrosion, ensuring the longevity and reliability of the storage solution. Steel sheets can be easily cleaned and maintained, making them suitable for storing a wide range of items, including tools, equipment, and products in industrial, commercial, or residential settings.

- Q: What are the advantages of using galvanized steel sheets?

- There are several advantages of using galvanized steel sheets. Firstly, galvanized steel sheets have a protective zinc coating that helps prevent rust and corrosion, making them highly durable and long-lasting. Secondly, they are resistant to extreme weather conditions, including rain, snow, and sunlight, which makes them suitable for outdoor applications. Additionally, galvanized steel sheets are versatile and can be easily formed into different shapes and sizes, making them ideal for various construction and manufacturing projects. Lastly, galvanized steel sheets are cost-effective as they require minimal maintenance and repair, reducing overall expenses in the long run.

- Q: What does steel plate "A3" mean?

- Using Q235 steel as punch material, after quenching without tempering, direct use, hardness of 36~40HRC, solved the punch in use in the phenomenon of fragmentation

- Q: Are steel sheets suitable for construction applications?

- Steel sheets are an ideal choice for construction applications due to their exceptional qualities. Renowned for their strength, durability, and versatility, steel is widely favored in the construction industry. Steel sheets find extensive use in various areas, including roofing, flooring, wall panels, structural frames, and cladding. They possess remarkable load-bearing capacity, enabling the construction of substantial and robust structures. Furthermore, steel sheets offer fire resistance, thereby enhancing the safety of buildings. Additionally, they are resilient against pests, rot, and corrosion, ensuring a prolonged lifespan for constructions. Moreover, steel sheets can be effortlessly fabricated and tailored to meet diverse construction requirements, making them a cost-effective and efficient option. In summary, steel sheets are highly suitable for construction applications due to their strength, durability, versatility, and various other advantageous properties.

- Q: Can steel sheets be used for manufacturing storage racks or shelves?

- Yes, steel sheets can be used for manufacturing storage racks or shelves. Steel is a durable and strong material that can withstand heavy loads, making it suitable for constructing storage racks or shelves that need to support various items. Additionally, steel sheets can be easily shaped and customized to accommodate different sizes and designs, making them highly versatile for manufacturing storage solutions.

- Q: Can steel sheets be used for manufacturing furniture?

- Yes, steel sheets can be used for manufacturing furniture. Steel is a strong and durable material that can be shaped and welded into various furniture designs. It is commonly used in the manufacturing of items such as tables, chairs, cabinets, and shelves. Steel furniture is known for its modern and sleek appearance, and it can be powder-coated or painted to add color and protect against corrosion.

- Q: Are steel sheets suitable for exterior wall cladding?

- Yes, steel sheets are suitable for exterior wall cladding. They provide durability, weather resistance, and can be customized to achieve various aesthetic designs. Steel cladding is popular for its strength, low maintenance requirements, and ability to withstand harsh environmental conditions, making it an ideal choice for exterior applications.

Send your message to us

Galvanized Corrugated Iron Sheet for Roofing Type Galvanized Steel Plain Sheet

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 300 m.t.

- Supply Capability:

- 1000000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords