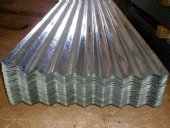

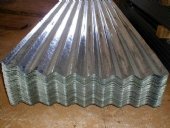

GI GL PPGI PPGL Corrugated sheets

- Loading Port:

- TIANJIN

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- 30000ton m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

We specialize in manufacturing galvanized steel coil, galvalume steel coil, prepainted steel coil and galvanized corrugated sheets.

Nowadays our company has grown up to a collectivized company . We are grateful to the cooperation partner who`s grown with us all the way. We hope we could make more friends from all over the world. Under the joint efforts of both sides we believe that we will continue to achieve win-win results based on mutual trust and mutual support.

Quick Details

| Standard: | Grade: | Thickness: | |||

| Place of Origin: | Brand Name: | Model Number: | |||

| Type: | Technique: | Surface Treatment: | |||

| Application: | Special Use: | Width: | |||

| Length: | Based Material: | Material: | |||

| Zinc Coated: | Spangle: | Shape: | |||

| Galvanized Type: | Business: | Payment Terms: | |||

| Packaging: | Delivery Detail: |

Packaging & Delivery

| Packaging Detail: | Fully seaworthy export packing with paper tube Each coil is wrapped in water-proof paper. |

| Delivery Detail: | about 15 days after the deposit if the quantity below 500 ton. |

Specifications

Corrugated gi/gl/ppgi Sheet

1.Thickness: 0.13mm-1.0mm

2.Width:750mm-1250mm

3. z40-z150g/m2

4.ISO 2000,SGS

our corrugated steel sheet:

GI Corrugated Steel Sheet | ||

No. | Item | Specification |

1 | Product Name | GI corrugated steel roofing sheet |

2 | Effective Width | 650mm to 1250mm |

3 | Thickness | 0.13mm-0.8mm |

4 | Material | Aluzinc or zinc coating PPGI steel coil |

5 | Zinc-coating | 40g/m2-150g/m2 |

6 | Color | white,blue or any RAL colors |

7 | length | 1m-11.8m according to the container |

8 | top color coating | 12um-25um |

9 | Back color coating | 7um-10um |

10 | HRB | 50-95 |

11 | Certificate system | ISO9001:2000 |

12 | base plate | hot-dipped galvanised steel sheet |

13 | Characters | light weight. Waterproof and fireproof and easy construction |

14 | Stardard | ASTM,JIS, DIN, GB |

- Q: Are steel sheets available in different colors?

- Yes, steel sheets are available in different colors.

- Q: Are steel sheets resistant to impact or damage?

- Steel sheets possess remarkable strength and durability, attributes that render them exceptionally resistant to impact and damage. Their robust tensile strength enables them to endure substantial loads and withstand external forces without deformation or breakage. Thus, they find extensive use in critical applications that demand impact resistance, such as construction, automotive manufacturing, and industrial settings. Furthermore, steel sheets exhibit exceptional resilience against extreme temperatures, corrosion, and environmental factors, further enhancing their overall resistance to damage. However, it is worth noting that the degree of impact or damage resistance may vary depending on the thickness, quality, and composition of the steel sheet.

- Q: How do steel sheets perform in terms of fire resistance?

- Steel sheets have excellent fire resistance properties. Due to their high melting point and low thermal conductivity, they can withstand high temperatures and prevent the spread of fire. Additionally, steel sheets do not contribute to the fuel load of a fire, making them a reliable choice for fire-resistant structures.

- Q: How do steel sheets perform in terms of electrical conductivity?

- Steel sheets are generally poor conductors of electricity due to their high resistance.

- Q: Are steel sheets suitable for oil rig platforms?

- Yes, steel sheets are suitable for oil rig platforms. Steel is commonly used in the construction of oil rig platforms due to its strength, durability, and ability to withstand harsh offshore conditions. It provides the necessary structural integrity and resistance to corrosion, making it a reliable choice for such applications.

- Q: How do steel sheets perform in terms of air permeability?

- Steel sheets have a very low air permeability, meaning that they do not allow air to pass through easily.

- Q: What are the electrical conductivity properties of steel sheets?

- Steel sheets have high electrical conductivity properties due to the presence of metallic bonds between iron atoms, allowing for the easy flow of electrons through the material.

- Q: Can steel sheets be recycled after use?

- Yes, steel sheets can be recycled after use. Steel is a highly recyclable material, and the recycling process saves energy and resources compared to producing new steel.

- Q: How do you remove stains or marks from steel sheets?

- To remove stains or marks from steel sheets, you can start by cleaning the surface with a mild detergent and water solution. If the stains persist, you can try using a non-abrasive cleaner or a stainless steel cleaner specifically designed for removing stains. For tougher stains, you may need to use a soft cloth or sponge along with a mild abrasive cleaner. It's important to always follow the manufacturer's instructions and test any cleaner on a small, inconspicuous area before applying it to the entire surface.

- Q: Can the steel sheets be used for soundproofing applications?

- Indeed, soundproofing applications can make use of steel sheets. Steel, being a dense and robust substance, possesses the ability to effectively obstruct and soak up sound waves. Employing steel sheets as a barrier or enclosure aids in diminishing the transfer of sound between different areas. Furthermore, steel sheets can be combined with other soundproofing materials like insulation or acoustic panels to heighten their soundproofing capabilities. Nevertheless, it is crucial to consider that the thickness and quality of the steel sheets significantly influence their effectiveness as soundproofing materials.

Send your message to us

GI GL PPGI PPGL Corrugated sheets

- Loading Port:

- TIANJIN

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- 30000ton m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords