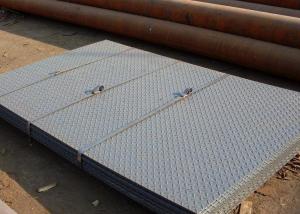

Checkered Plate

- Loading Port:

- Xingang Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 100MT m.t.

- Supply Capability:

- 100000MT/year m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification of Checkered Plate:

1. We are specialist in producing and supplying checkered plate to our customers all over the world

Please refer yourself to the informations in below table.

Thickness | 2.5-8.0mm |

Width | 1250mm,1500mm,1800mm,2000mm.,2500mm or as required |

Length | 2000-12000mm |

Standard | AISI, ASTM, BS, DIN, GB, JIS |

Material | A36,SS400, Q195, Q 235,Q345 |

Tehnique | Hot Rolled |

Payment | TT ,L/C |

Packing | Standard seaworthy packing or as required |

Market | Mild east, Africa, Asia North/South America, Europe |

Certificate | SGS China |

Note: we do possess lots of advantages, just as followings:

a) The unfairness of our checkered steel sheet must be less than 10mm each meter

b) The surface of our hot rolled checkered steel sheet is free from bubble, scab, crack, fold, edge delamination and so on.

c) The height of our hot rolled checkered steel sheet will be maintained between 0.2~0.3 times to thickness of steel substrate, but more than 0.5mm at least.

2. The regular sections we provide are shown in the below table:

Base Thickness(MM) | AllowedTolerance ofBaseThickness(%) | Theoretical Mass (KG/M²) | ||

The Pattern | ||||

Rhombus | Beam | Pea | ||

2.5 | ±0.3 | 21.6 | 21.3 | 21.1 |

3.0 | ±0.3 | 25.6 | 24.4 | 24.3 |

3.5 | ±0.3 | 29.5 | 28.4 | 28.3 |

4.0 | ±0.4 | 33.4 | 32.4 | 32.3 |

4.5 | ±0.4 | 37.3 | 36.4 | 36.2 |

5.0 | 0.4~-0.5 | 42.3 | 40.5 | 40.2 |

5.5 | 0.4~-0.5 | 46.2 | 44.3 | 44.1 |

6.0 | 0.5~-0.6 | 50.1 | 48.4 | 48.1 |

7.0 | 0.6~-0.7 | 59.0 | 52.5 | 52.4 |

8.0 | 0.7~-0.8 | 66.8 | 56.4 | 56.2 |

3. Chemical Composition of Checkered Plate:

Our hot rolled checkered plate is usually to roll with ordinary carlbon structure steel. The carbon content value can reach more than 0.06%,0.09% or 0.10%,the maximum value is 0.22%. The silicon content value ranges from 0.12-0.30%, the manganese content value ranges from 0.25-0.65%, and the phosphorus and sulphur content value is commonly less than 0.045%.

Applications of Checkered Plate:

1.Definition: The hot rolled steel sheet with raised pattern on surface. The raised pattern could be shaped as rhombus,bean or pea. There is not only one kind of pattern on the checkered steel sheet, but also a complex of two or more than two kinds of pattern on surface of one checkered steel sheet. It also could be called as grid steel sheet.

2.Character: The Hot Rolled Checkered Steel Sheet possesses a variet of advantages, such as beauty in appearance,skip resistance and saving steel material.Generally speaking,in order to test the mechanical property or the quality of hot rolled checkered steel sheet, the shaping rate and the pattern height should be tested primarily.

3. In conclusion, the hot rolled checkered steel sheet can usually be used in the industry of ship-building,boiler,automobil,tractor,train- building and architecture. In details, there are many demands for hot rolled checkered steel sheet to make floor,ladder at workshop,work frame pedal,ship deck,car floor and so on.

Package & Delivery of Checkered Plate:

1. The items to be prepared for packing include: narrow steel strip, crude steel belt or edge angle steel, kraft paper or galvanized sheet.

2. The hot rolled checkered steel plate should be wrapped with kraft paper or galvanized sheet ouside, and it should be bundled with narrow steel strip, three or two narrow steel strip in longitudinal direction,and the other three or two strips in transverse direction. Furthermore, in order to fix the hot rolled checkered steel sheet and avoid the strip at edge shall be broken, the crude steel belt cut into square should be put under the narrow steel strip on the edge. Of course, the hot rolled checkered steel sheet could be bundled without kraft paper or galvanized sheet. It depends on customer’s requirement.

3. In consideration of the transportaion from mill to loading port, the truck will be usually used. And the maximum quantity for each truck is 40mt.

4. All in all, we could do in accordance with customer's request.

- Q: Are steel sheets suitable for food storage applications?

- Food storage applications can benefit greatly from the use of steel sheets. This material offers exceptional durability and versatility, with its resistance to corrosion making it an ideal option for storing food. Steel sheets create a hygienic and secure environment for food, as they are non-porous and do not retain odors or flavors. Moreover, they provide reliable protection against contaminants and pests, ensuring the maintained quality and freshness of the stored food. Furthermore, steel sheets are effortlessly cleaned and maintained, making them the perfect choice for food storage facilities, restaurants, and any other setting where food safety is of utmost importance.

- Q: What is the maximum size of steel sheets available?

- The maximum size of steel sheets available can vary depending on the manufacturer and specific requirements. However, commonly available steel sheets can range in size from 4 feet by 8 feet (1.2 meters by 2.4 meters) to larger dimensions such as 10 feet by 20 feet (3 meters by 6 meters).

- Q: Can the steel sheets be used for magnetic shielding?

- Yes, steel sheets can be used for magnetic shielding due to their high magnetic permeability, which helps to redirect and absorb magnetic fields.

- Q: Can steel sheets be used for transportation equipment?

- Yes, steel sheets can be used for transportation equipment. Steel is a widely used material in the transportation industry due to its strength, durability, and cost-effectiveness. Steel sheets are commonly used in the construction of various transportation vehicles such as cars, trucks, buses, trains, ships, and airplanes. They can be used for the body panels, chassis, frames, and other structural components of these vehicles. Steel sheets offer excellent mechanical properties, including high tensile strength and impact resistance, making them suitable for withstanding the stresses and demands of transportation applications. Additionally, steel is also known for its ability to be easily formed and welded, allowing manufacturers to create complex shapes and structures required for transportation equipment.

- Q: What are the different sheet metal folding techniques for steel sheets?

- Steel sheets can be subjected to various sheet metal folding techniques. These techniques find extensive application in industries like automotive, aerospace, and construction for creating intricate shapes and structures. Some frequently used sheet metal folding techniques for steel sheets comprise: 1. Box and Pan Folding: This technique entails bending the sheet metal along multiple parallel edges to form a box-shaped structure. It is commonly utilized for manufacturing enclosures, cabinets, and trays. 2. Hemming: Hemming is employed to fold the edges of a sheet metal component, enhancing its rigidity and eliminating sharp edges. It finds prominent usage in the automotive sector for fabricating panels and body parts. 3. Brake Press Folding: Brake press, a machine tool utilizing hydraulic or mechanical press, is employed to bend the sheet metal. Precise and accurate folding is facilitated by adjusting the bend's angle and depth. Brake press folding is a frequently employed technique in sheet metal fabrication. 4. Roll Forming: Roll forming is a continuous bending process wherein the sheet metal passes through a series of rollers, gradually shaping it into the desired profile. It is suitable for creating elongated and continuous shapes like tubes and channels. 5. Rotary Folding: In this technique, a rotating tool is utilized to fold the sheet metal along a curved or circular path. It is often applied to create rounded edges, curves, and cylindrical shapes. 6. Folding Machines: Folding machines are specifically designed to fold sheet metal by applying pressure along a predetermined line. These machines can be programmed to carry out various folding operations, including simple bends, complex shapes, and multiple folds. Each of these sheet metal folding techniques possesses its own advantages and limitations. The selection of a particular technique depends on factors such as the design's complexity, required precision, and production volume. Skilled craftsmen and specialized machinery are frequently employed to ensure accurate and efficient folding of steel sheets.

- Q: Can steel sheets be used for manufacturing industrial equipment?

- Indeed, the utilization of steel sheets for the production of industrial equipment is possible. Due to its robustness, longevity, and resistance to deterioration, steel is a multifaceted and extensively employed substance in various industries. When it comes to the manufacturing of industrial equipment, steel sheets can be effortlessly shaped, cut, and formed into diverse components. These components are essential for the creation of machinery, tools, storage tanks, conveyors, and structural supports. Furthermore, steel sheets possess exceptional load-bearing capacity, rendering them suitable for demanding applications in sectors like construction, automotive, aerospace, energy, and manufacturing. Moreover, steel sheets can be subjected to treatments or coatings to augment their properties, such as enhancing their resistance to heat, chemicals, or wear. In conclusion, due to their durability, adaptability, and dependability, steel sheets are an immensely popular choice for the manufacturing of industrial equipment.

- Q: What are the different methods of joining steel sheets together?

- There exists a variety of techniques for connecting steel sheets, each possessing unique benefits and applications. Some commonly employed techniques include: 1. Welding: Utilized extensively, welding effectively joins steel sheets by melting their edges and fusing them together through the application of heat. Different welding processes, including arc welding, gas welding, and spot welding, are available, each tailored to specific applications. 2. Riveting: Riveting, a mechanical method, utilizes metal fasteners called rivets to connect steel sheets. Rivets are inserted into pre-drilled holes in the sheets and secured in place by hammering or pressing. Riveting is renowned for producing robust and long-lasting joints. 3. Bolting: Bolting employs bolts and nuts to hold steel sheets together. Holes are drilled through the sheets, and bolts are inserted from one side, with nuts tightened on the other side to secure the joint. Bolting offers the advantages of being quick, easy to assemble, and allows for disassembly if necessary. 4. Adhesive bonding: Adhesive bonding employs specialized adhesives to join steel sheets. The adhesive is applied between the surfaces to be joined and forms a strong bond as it cures. This method is commonly employed in industries where welding may distort the materials or is not feasible due to the specific materials involved. 5. Mechanical fastening: Mechanical fasteners such as screws, self-tapping screws, or nails may be used to join steel sheets. These fasteners create a sturdy connection by penetrating the sheets and holding them in place. Mechanical fastening is relatively swift and does not necessitate any specialized equipment. 6. Clinching: Clinching is a cold forming process that connects steel sheets by deforming the material without the use of external heat. It involves pressing the sheets together and forming a mechanical interlock. Clinching is frequently employed in the automotive industry due to its high-speed production capabilities and joint strength. Each technique possesses its own advantages based on factors such as joint strength, ease of assembly, cost, and specific application requirements. The selection of a joining technique depends on the intended purpose of the joint, material properties, and the environmental conditions to which the joint will be exposed.

- Q: Can steel sheets be galvanized?

- Yes, steel sheets can be galvanized. Galvanizing is a process of applying a protective zinc coating to steel to prevent corrosion, and it can be done on steel sheets as well.

- Q: What are steel sheets made of?

- Steel sheets are made of steel, which is an alloy primarily composed of iron and carbon, along with small amounts of other elements such as manganese, silicon, and traces of other metals.

- Q: What is the thickness tolerance for steel sheets?

- The thickness tolerance for steel sheets typically depends on the specific grade and manufacturing process, but it generally ranges from +/- 0.005 to 0.015 inches.

1. Manufacturer Overview

| Location | Qianan, China |

| Year Established | 2005 |

| Annual Output Value | Above US$ 1,300 Million |

| Main Markets | Mid East; Eastern Europe; North America |

| Company Certifications |

2. Manufacturer Certificates

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period |

3. Manufacturer Capability

| a) Trade Capacity | |

| Nearest Port | Tianjin |

| Export Percentage | 40% - 60% |

| No.of Employees in Trade Department | 21-50 People |

| Language Spoken: | English; Chinese |

| b) Factory Information | |

| Factory Size: | Above 800,000 square meters |

| No. of Production Lines | Above 10 |

| Contract Manufacturing | OEM Service Offered; |

| Product Price Range | High; Average |

Send your message to us

Checkered Plate

- Loading Port:

- Xingang Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 100MT m.t.

- Supply Capability:

- 100000MT/year m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords