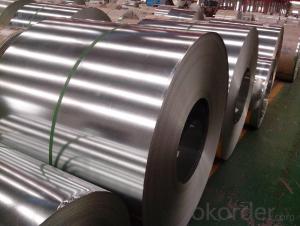

Galvanized Iron Sheet, GI Sheet, Galvanized Sheet Metal Prices

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 500 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

deformed steel bar grade 40

material: HRB400, BS4449 GR460B

size: 8-36mmx12m.

short delivery time by bulk or container

deformed steel bar grade 40

material: HRB400, BS4449 GR460B

size: 8-36mmx12m.

short delivery time with bulk or container

packing: Mill standard export packing in bundles/coil, around 2tons/bundle.

country of Origin: China

delivery Time: Within a 35 days

Shipment: by bulk vessel or by container

Leading goods:

section steel:angles,channels,I-beam,H-beam;

coils:cold/hot rolled coils,PPGI,galvanized coils,plate,checkered plate,cutting steel plate,steel strip;

wire rod:steel wire,deformed wire,bar;

pipe:seamless pipe,rectangular pipe,welded pipe,spiral welded pipe,pipe fittings;

stainless steel:steel sheets,stainless steel strips,stainless bar,stainless tube;

special:weathering steel,shipbuilding steel;

construction steel:C-channel,Z-channel,T-bar,high-speed divider plate,corrugated steel plate,steel grating.

Advantage:

We are the spot supplier, Six huge warehouses which can hold 20,000 MT goods.

It makes the cost lower than others,we can provide the competitive price for you.

Delivery time:

Normal sizes can be provided in 7days, the others should be ready in 30---45 days.

Further treatment:

We can offer cutting,painting,drilling holes,bending,threading, welding,galvanization,packing etc.

Security interest:

We have already passed the ISO9001, BV and SGS authentication which makes the quality secured.

If you have the interest in any of the products we can provided, pls don't hesitate to connect with me. Looking forward to cooperate with you.

FAQ of Steel Deformed Bar

1. More than 10 years experience in this industry

2. 100,000 tons exporting per month

3. Professional foreign trade tea

4. OEM&ODM capacity

5. High quality assured & competitive price

6. Try our best to meet your needs & save your budget

7. Very popular in Southeast Asia, Africa, Mid-East and South America etc.

8. VIP membership system, first time customers and long-term cooperation customers can get extra discount on some products.

During our home decoration, many people prefer to use bright shiny stainless steel sheet as some parts of the decorative material. However, a wide range of stainless steel sheet, many friends are not very clear about the differences between them, and then, how to classify the Stainless steel sheet?

Production material of stainless steel plate is stainless steel; stainless steel has corrosion-resistant, high temperature characteristics, which makes it very popular with by the majority of consumers in the market. However, plate type on the market variety; here we will introduce two common classification of stainless steel sheet.

According to the manufacturing process

Stainless steel sheet made according to the method can be divided into cold-rolled sheet and hot-rolled sheet.

Hot-rolled stainless steel sheet is heated to high temperatures after the iron billet, then rolling roughing and finishing of steel sheet formation. After hot-rolled stainless steel sheet has good toughness, good stretchability. However, hot-rolled stainless steel sheet has a huge drawback is made of stainless steel sheet hardness is not very high; the texture is not very hard.

- Q: Can steel sheets be used for automotive chassis?

- Yes, steel sheets can be used for automotive chassis. Steel is a common material used in the construction of automotive chassis due to its high strength, durability, and cost-effectiveness. It provides the necessary structural integrity and rigidity required to support the vehicle's weight and withstand various stresses and impacts.

- Q: What are the different bending radius options for steel sheets?

- The bending radius options for steel sheets can vary depending on the thickness and type of steel being used. However, common bending radius options for steel sheets typically range from 0.5 times the thickness of the sheet to 2 times the thickness of the sheet.

- Q: What is hot and cold rolled steel plate? How to distinguish? What high hardness? Which will produce noisy eye?

- By definition, ingot or billet is difficult to deform under normal temperature, easy processing, generally heated to 1100 to 1250 DEG C for rolling, the rolling process of hot rolled steel rolling. Most are called hot method. But because the surface under high temperature steel is easy to produce iron oxide, the surface roughness of hot rolled steel, size fluctuation so large, smooth surface, precise size, good mechanical properties of the hot rolled steel, semi-finished or finished products and raw materials for the production of cold rolling method. Under normal temperature, generally understood as cold, from the metal science point of view, the boundaries of cold rolling and hot rolling should be differentiated by the recrystallization temperature is lower than rolling recrystallization. The temperature is higher than the recrystallization temperature of cold rolling, rolling for hot rolled steel. The recrystallization temperature is 450 ~ 600 degrees. The difference: the simple point that 1, cold rolled plate surface has a certain gloss hand feels smooth, Similar to that used for drinking water is very common, such as hot rolled.2 steel cup without pickling treatment, is on the market and many are similar to ordinary steel plate surface, rusty surface is red, the surface of the rusty purple black (iron oxide).The performance advantages of cold rolled plate and strip is: 1, high precision, cold rolled strip thickness not more than 0.01~0.03mm.2, thinner, cold rolled steel strip rolling thickness 0.001mm hot rolling; now the thin can reach 0.78mm.3, the surface quality is more superior, cold rolled steel plate can even produce mirror surface; and the surface of hot rolled plate there are defects such as pitting of iron oxide,.4, cold rolled plate can be adjusted according to the running properties such as tensile strength and technological properties such as stamping performance requirements of the user.

- Q: Can steel sheets be used for solar panel frames?

- Yes, steel sheets can be used for solar panel frames. Steel is a commonly used material for solar panel frames due to its strength, durability, and ability to withstand harsh weather conditions. It provides structural support and stability to the solar panels, allowing them to be securely mounted and protected.

- Q: What is the typical yield strength of stainless steel sheets?

- The yield strength of stainless steel sheets can vary based on factors such as the grade and thickness of the material. On average, stainless steel sheets possess a yield strength within the range of 30,000 to 80,000 psi. It should be noted that the yield strength differs among various grades of stainless steel, such as 304, 316, or 430. Moreover, the thickness of the sheet also impacts the yield strength, with thinner sheets generally exhibiting lower yield strengths when compared to thicker sheets. Therefore, it is advisable to refer to the manufacturer or supplier's specific grade and thickness specifications to ascertain the precise yield strength of a given stainless steel sheet.

- Q: Can steel sheets be used for cladding or façade applications?

- Yes, steel sheets can be used for cladding or façade applications. Steel is a versatile and durable material that can provide structural support, protection, and an aesthetically pleasing appearance to buildings. It is commonly used for cladding and façade applications due to its strength, resistance to weathering, and variety of finishes available.

- Q: Can steel sheets be used for architectural facades?

- Indeed, architectural facades can make use of steel sheets. The reason for the widespread use of steel sheets in architectural facades is their durability, strength, and aesthetic charm. One can effortlessly mold steel sheets into various shapes and sizes, thereby enabling the creation of imaginative and distinctive designs. Furthermore, steel sheets can be coated or finished with different materials to not only enhance their appearance but also safeguard them from corrosion. In addition to all these advantages, steel is an environmentally friendly choice as it is recyclable and reusable, making it a sustainable material for architectural facades. Overall, architects and designers seeking to fashion visually stunning and long-lasting facades can rely on steel sheets, which provide a versatile and dependable option.

- Q: How do steel sheets compare to other materials like aluminum or stainless steel?

- Steel sheets have several advantages over other materials like aluminum or stainless steel. Firstly, steel sheets are generally much stronger and more durable than aluminum or stainless steel sheets. This makes them ideal for applications that require high strength and resistance to wear and tear. Secondly, steel sheets are more cost-effective compared to stainless steel sheets. Steel is usually less expensive to produce and purchase, making it a more economical choice for many industries. Additionally, steel sheets can be easily recycled, further reducing their overall cost and environmental impact. On the other hand, aluminum sheets are lighter in weight than steel sheets, which can be advantageous in certain applications where weight is a concern, such as in the aerospace industry. Aluminum is also naturally resistant to corrosion, making it a suitable choice for outdoor applications or environments with high humidity. Stainless steel sheets, on the other hand, are highly resistant to corrosion and staining, making them ideal for applications where hygiene and aesthetics are important, such as in the food and medical industries. Stainless steel sheets also have excellent heat resistance properties, making them suitable for high-temperature applications. In summary, steel sheets offer superior strength and durability compared to aluminum or stainless steel sheets, while also being more cost-effective. However, aluminum and stainless steel sheets have their own unique properties that make them suitable for specific applications. The choice between these materials ultimately depends on the specific requirements and constraints of the project or industry.

- Q: How do steel sheets compare to stainless steel sheets in terms of corrosion resistance?

- Stainless steel sheets have superior corrosion resistance compared to steel sheets, thanks to the presence of chromium that forms a protective layer against corrosion.

- Q: Are steel sheets suitable for interior design applications?

- Yes, steel sheets are suitable for interior design applications. They offer a sleek and modern aesthetic, are durable and long-lasting, and can be customized to fit various design styles. Steel sheets can be used for wall cladding, ceilings, decorative panels, furniture, and other interior elements, adding a contemporary and industrial touch to any space.

Send your message to us

Galvanized Iron Sheet, GI Sheet, Galvanized Sheet Metal Prices

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 500 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords