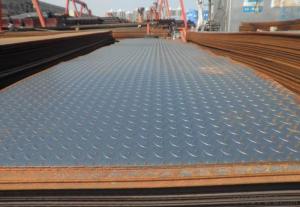

Hot rolling steel checkered plate

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

The pattern shape

A tread surface plate is called a pattern plate, English Name: Diamond plate. The pattern of lentil shaped, diamond, round bean

Shape oblate shape, mixed, the market to the most common lentil shaped.

The specific application of

Pattern plate appearance, can slip, enhanced performance, and many other advantages,such as saving steel in transportation, construction, decoration, equipment around the floor,machinery, shipbuilding and other fields has been widely applied. In general, the use of side of the mechanics pattern plate performance, mechanical performance requirements is not high, so the pattern plate quality mainly flowering rate, as the pattern of pattern height, height difference. At present the common thickness on the market ranging from 2.0-8mm, the width of common 12501500mm two.

The relevant standards

In accordance with the provisions of national standards GB/T 3277 pattern plate, patternheight should be greater than or equal to the thickness of the 20% substrate.

Theoretical calculation of weight

Pattern plate, according to the material (aluminum alloy, stainless steel, ordinary steel etc.)different patterns of different shapes and different weight per square meter adjustment.

Class B common carbon steel rolling, the provisions of chemical composition meet the GB700"ordinary carbon structural steel technical conditions".

Pattern plate of high no less than 0.2 times the thickness of the substrate;

Checkered steel plate according to the weight of the actual weight of delivery or theory;

Mark example: made of Q235-A, size 4*1000*4000mm.

Peaberry pattern plate, mark it as: round bean plate Q235-A-4*1000*4000-GB/T 3277-91

Diamond pattern plate, mark it as: diamond pattern plate B 3-4*1000*4000-GB 3277-82

Steel with hot-rolled state of delivery;

Checkered steel plate surface without bubble, scar, crack, folding and inclusion, plate without delamination.

The surface quality is divided into two levels:

The general accuracy: steel surface with a thin layer of oxide scale and rust allowed, due to other local defects on the surface of oxide scale formed off rough and height or depthexceeds the allowable deviation of the ancient.

Burr height is not obvious and not more than the individual trace lines high allows patterns.The largest area of a single defect pattern with the square of the length of not more than.

High precision: steel surface with a thin layer of oxide scale, allowing the rust and the height or depth of no more than other local defects of half the thickness tolerance.

Pattern intact, a height of not more than half of the tolerance of thickness of the local slightburr allowed patterns.

- Q: How do steel sheets handle thermal expansion?

- Steel sheets handle thermal expansion by expanding and contracting in response to changes in temperature. Like all materials, steel expands when heated and contracts when cooled. However, steel has a relatively low coefficient of thermal expansion compared to other materials, meaning it expands and contracts less for a given change in temperature. This makes steel sheets more resistant to warping or buckling due to thermal expansion. Additionally, steel is a strong and durable material, which allows it to handle the stresses caused by thermal expansion without significant damage. To further mitigate the effects of thermal expansion, engineers often design structures with expansion joints or use techniques such as pre-stressing and anchoring to accommodate the expansion and prevent damage. Overall, steel sheets are able to effectively handle thermal expansion due to their properties and the design considerations taken into account.

- Q: How do steel sheets handle thermal expansion?

- Thermal expansion is managed by steel sheets through their ability to expand and contract in response to temperature fluctuations. When steel is heated, it expands, and when it is cooled, it contracts, just like any other material. However, steel has a relatively low coefficient of thermal expansion compared to other materials, meaning it expands and contracts less for a given change in temperature. This characteristic makes steel sheets more resistant to warping or buckling caused by thermal expansion. Moreover, steel is a robust and long-lasting material, enabling it to withstand the stresses resulting from thermal expansion without significant damage. To further address the effects of thermal expansion, engineers often incorporate expansion joints into structures or employ techniques such as pre-stressing and anchoring to accommodate the expansion and prevent harm. As a result of these properties and design considerations, steel sheets are able to effectively manage thermal expansion.

- Q: Can steel sheets be used for mezzanine floors?

- Yes, steel sheets can be used for mezzanine floors. Steel sheets are commonly used in the construction of mezzanine floors due to their strength, durability, and ability to support heavy loads. They provide a solid and stable surface for various applications, such as storage, industrial operations, or additional office space.

- Q: Can steel sheets be used for storage containers?

- Yes, steel sheets can be used for storage containers. Steel is a strong and durable material that can withstand heavy loads and harsh weather conditions, making it ideal for storage containers. It offers excellent protection against moisture, pests, and theft. Steel containers are commonly used in various industries such as shipping, construction, and warehousing. They are also popular for temporary storage solutions and can be easily transported and stacked. Additionally, steel containers can be customized with various accessories such as doors, windows, and ventilation systems to suit specific storage needs.

- Q: What are the different surface finishes for pre-painted steel sheets?

- Some of the different surface finishes for pre-painted steel sheets include smooth, textured, matte, glossy, and metallic finishes.

- Q: What are the different sheet metal welding techniques for steel sheets?

- There are several sheet metal welding techniques commonly used for steel sheets, including spot welding, seam welding, and TIG welding. Spot welding involves joining two metal sheets by applying pressure and heat at specific points, creating a strong bond. Seam welding, on the other hand, involves continuously welding along the length of a joint, creating a continuous welded seam. TIG welding, also known as tungsten inert gas welding, uses a non-consumable tungsten electrode to create an arc that melts the metal, forming a weld pool that fuses the steel sheets together. Each technique has its own advantages and is chosen based on the specific requirements of the project.

- Q: How are steel sheets measured and classified?

- Steel sheets are typically measured and classified based on their thickness, which is commonly referred to as gauge. The gauge of steel sheets is determined by measuring the thickness of the sheet in terms of its weight per square foot or meter. The higher the gauge number, the thinner the sheet. Steel sheets are further classified based on their composition, finish, and intended application, such as hot-rolled, cold-rolled, galvanized, or stainless steel sheets.

- Q: How do steel sheets perform in fire-rated applications?

- Steel sheets perform exceptionally well in fire-rated applications. Due to their high melting point and excellent heat resistance, they offer superior protection against fire and help to contain its spread. Steel sheets are widely used in fire-rated walls, doors, and ceilings, as they maintain their structural integrity even at extremely high temperatures. Additionally, they contribute to fire safety by limiting the release of toxic gases and smoke, making them a reliable choice for fire protection in various industries and buildings.

- Q: How do steel sheets handle impact resistance?

- Steel sheets are known for their exceptional impact resistance. Due to their high strength and toughness, steel sheets can effectively absorb and distribute the energy produced by an impact, minimizing the damage caused. This is primarily attributed to the microstructure of steel, which consists of a crystalline lattice that allows for the deformation and reformation of the material under stress. When subjected to an impact, steel sheets undergo plastic deformation, which enables them to absorb the energy and prevent it from propagating further. The ability of steel sheets to handle impact resistance is further enhanced by their composition, which often includes alloying elements such as manganese, chromium, and nickel. These elements increase the hardness and strength of the steel, making it even more resistant to deformation and fracture. As a result, steel sheets are widely used in various applications where impact resistance is crucial, including automotive manufacturing, construction, and heavy machinery industries.

- Q: Can steel sheets be used for manufacturing machinery or equipment?

- Yes, steel sheets can be used for manufacturing machinery or equipment. Steel is a commonly used material for its strength, durability, and versatility, making it suitable for various industrial applications. Steel sheets can be cut, shaped, and welded to create different parts and components of machinery or equipment, providing stability and structural integrity to the final product.

Send your message to us

Hot rolling steel checkered plate

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords