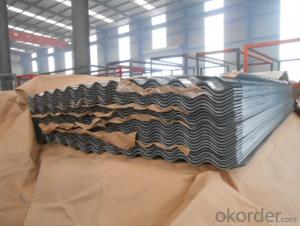

Corrugated Hot -Dipped Galvanized Steel Sheets

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Corrugated Hot Dipped Galvanized Steel Sheets

Description:

Corrugated steel sheet is the colored steel plate which has been wave formed with the cold rolling treatment, trough especial coated dispose, the color coated steel panel’s guaranty is 12-15 years.

Pressing steel panel with the clear line, and many colors for choice, suitable for any different building style materials, achieving satisfy effects;

Pressing steel panel can be freely incised, it can satisfy the especially designing demands. It apply on convenient construction, and anti-seismic performance, fire proof, waterproof, free of maintenance, ect.

Base sheet : galvanized steel sheet, pre painted galvanized steel sheet

Application:

With excellent cold bending molded manufacturablity, good decoration effect, strong anti-corrosion ability, are also pollution-free and easily recycled. Accordingly, they can be used as final products and basic plates of color coated steel coils and widely applied in construction, home appliances, decoration, ect.

Pressing steel panel with the clear line, and many colors for choice, suitable for any different building style materials, achieving satisfy effects;

Product Specification:

Thickness tolerance: (+/-0.01mm)

Zinc coating: 50-180g/m2

Standard:jis g 3302, sgch

Package: 2- 3 ton/pallet

Specs: 0.14-0.8mm x 900mm x 2000mm

Width:700-1250mm( 750mm,900mm,1215mm,1250mm,1000mm the most common)

Surface:regular/mini/zero spangle, chromated, skin pass, dry etc.

Package:Standard seaworthy export packing: 3 layers of packing, inside is kraft paper,water plastic film is in the middle and outside GI steel ,sheet to be covered by steel strips with lock.

FAQ:

1.How many pieces for one package?

The pieces for one tone is decided by the thickness of the sheet, but we can make it according to your requirements in the reasonable range.

2. Do you have pallets for the package?

Yes, we must use pallets for the package in order to load.

3. Could you produce the sheets according to our design?

Yes, we can.

- Q: What are the standard dimensions for steel sheets?

- The specific type and grade of steel being used can cause variation in the standard dimensions for steel sheets. Generally, steel sheets are found in standard sizes of 4 feet by 8 feet or 4 feet by 10 feet. These dimensions are widely used in the construction industry and can be easily obtained from steel suppliers. Moreover, steel sheets can be tailored to specific dimensions to meet the requirements of a particular project. It is crucial to seek guidance from a steel supplier or manufacturer to ascertain the precise dimensions available for the desired type of steel sheet.

- Q: Are the steel sheets suitable for agricultural applications?

- Yes, steel sheets are suitable for agricultural applications due to their durability, strength, and resistance to rust, making them ideal for construction of farm buildings, equipment, and fencing.

- Q: Are steel sheets suitable for electrical grounding applications?

- Yes, steel sheets can be suitable for electrical grounding applications. Steel is a good conductor of electricity, and it can effectively dissipate electrical charges to the ground. Steel sheets are commonly used in grounding applications because of their durability, strength, and cost-effectiveness. They can be easily installed and provide a reliable connection to the earth, ensuring a safe path for electrical currents to flow in case of a fault or surge. However, it is important to ensure that the steel sheets are properly installed and maintained, as any corrosion or damage can affect their conductivity and effectiveness in grounding electrical systems.

- Q: How are steel sheets used in construction?

- Steel sheets are commonly used in construction for a variety of purposes, including roofing, walls, and structural support. They are often used to create sturdy and durable structures due to their high strength and resistance to corrosion. The sheets can be shaped and welded into different forms to meet specific construction needs, providing a versatile and cost-effective solution.

- Q: How do steel sheets perform in high-pressure applications?

- Steel sheets perform well in high-pressure applications due to their high strength and durability. They are able to withstand the force exerted by the pressure, maintaining their structural integrity. Additionally, steel sheets have good resistance to deformation and can effectively distribute the pressure, reducing the risk of failure.

- Q: What are the different surface protection methods for steel sheets?

- There are several surface protection methods for steel sheets, including galvanizing, powder coating, painting, and epoxy coating. Galvanizing involves applying a layer of zinc to the steel surface to prevent corrosion. Powder coating is a process where a dry powder is applied electrostatically and then cured under heat, creating a durable and protective coating. Painting involves applying a liquid paint to the steel surface, providing a barrier against corrosion. Epoxy coating is a type of paint that is specially formulated with epoxy resins, offering excellent adhesion and chemical resistance.

- Q: What does steel plate "A3" mean?

- Using Q235 steel as punch material, after quenching without tempering, direct use, hardness of 36~40HRC, solved the punch in use in the phenomenon of fragmentation

- Q: Are steel sheets resistant to water or moisture damage?

- Yes, steel sheets are generally resistant to water or moisture damage due to their non-porous nature. However, prolonged exposure to water or moisture can lead to corrosion over time if the steel is not properly protected or coated.

- Q: What are the different sheet metal bending techniques for steel sheets?

- There are several sheet metal bending techniques commonly used for steel sheets. These techniques allow for the manipulation and shaping of steel sheets to achieve desired forms and angles. Some of the most common techniques include: 1. V-bending: This technique involves using a V-shaped punch and die set to create a sharp bend in the steel sheet. The material is placed between the punch and die, and force is applied to form the desired angle. V-bending is a versatile technique that can create various angles and shapes. 2. Air bending: In this technique, a punch is used to press the steel sheet into a V-shaped die, but without completely contacting the material. The bending is achieved by controlling the depth of penetration of the punch into the material. Air bending allows for greater flexibility in terms of angle adjustments and requires less force than other techniques. 3. Edge bending: As the name suggests, this technique involves bending the edge of the steel sheet. It is commonly used to create flanges or edges with specific angles. Edge bending is achieved by clamping the sheet between a punch and a die, and applying force to bend the material along the edge. 4. Bottom bending: This technique is used to create larger bends in steel sheets. It involves clamping the sheet between a punch and a V-shaped die, and then applying force to bend the material around the die. Bottom bending is suitable for creating U-shaped parts or boxes. 5. Roll bending: Also known as cylindrical bending, this technique is used to create cylindrical or curved shapes in steel sheets. The sheet is passed through a set of rolls, which gradually bend the material into the desired shape. Roll bending is commonly used in the production of pipes, tubes, and cylinders. 6. Coining: Coining is a precision bending technique that creates crisp, sharp bends. It involves pressing the steel sheet between a punch and a die, with the die featuring a sharp edge. The material is subjected to high pressure, resulting in a precise and defined bend. These are just a few of the many sheet metal bending techniques available for steel sheets. Each technique has its advantages and applications, and the choice of technique depends on factors such as the desired angle, the thickness of the sheet, and the complexity of the shape being formed.

- Q: What are the common thicknesses for roofing steel sheets?

- Roofing steel sheets come in a variety of thicknesses, typically ranging from 0.4mm to 0.8mm. Nevertheless, the actual thickness required will be influenced by factors like the roofing system type, regional climate, and desired durability level. In regions prone to harsh weather, thicker steel sheets, like those around 0.8mm, are commonly employed, whereas thinner sheets may suffice for less challenging environments. Consulting with a roofing expert or manufacturer is crucial to ascertain the ideal thickness for a particular roofing undertaking.

Send your message to us

Corrugated Hot -Dipped Galvanized Steel Sheets

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords