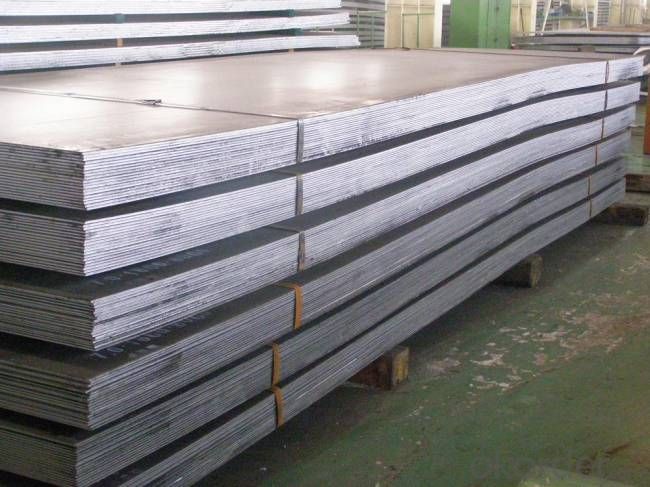

304 Stainless steel plates from okorder.com

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m.t.

- Supply Capability:

- 20000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Quick Details

Standard: AISI, ASTM, BS, DIN, GB, JIS

Grade: 201,202,304,304L,309S,310S,316,316L,316Ti,317L,321,347H,409,409L,410,4

Thickness: 0.3mm-300mm

- Type: Steel Plate

Technique: Hot Rolled

Surface Treatment: 2B, BA, No.1, Hair Line(HL), Mirror (8K), No.4 ,PVC etc

Width: 10mm-3000mm

Length: 1000mm-11000mm

Packaging & Delivery

| Packaging Details: | Standard seaworthy packing type or as pe customers request |

|---|---|

| Delivery Detail: | Within 10-35 days |

Specifications

1.Material:201,202,304,304L,309S,310S,316,316L,316Ti,317L,321,347H,409,409L,410,410S,420,430,etc.

1.Material:201,202,304,304L,309S,310S,316,316L,316Ti,317L,321,347H,409,409L,410,410S,420,430,etc.

2. Standard: ASTM,AISI,ASME,JIS,SUS,DIN,EN,GB,BS,etc;

3. Thickness: 0.3mm-200mm or as customer’s requirement

4. Width: 10mm-3000mm or as customer’s requirement

5. Length: 1000mm-11000mm or as customer’s requirement

6. Surface: 2B, BA, No.1, Hair Line(HL), Mirror (8K), No.4 ,PVC etc

7. Technical processing: Hot Rolled/Cold Rolled

8. Packaging:

Standard export packing-For stainless steel sheet

1).surface polish

2). bundle package

3). wooden case ,wooden pallet package

4).container or bulk

5).And can pack according to customer request;

9. Application:

1): Construction feild,shipping building industry

2): Petroleum and Chemical Industries

3): Food and Machenical Industries

4): Boiler Heat Exchange

5): Machinery and Hardware Industries

- Q: What is the typical thickness tolerance of a steel sheet?

- Depending on the specific industry and application requirements, the thickness tolerance of a steel sheet can vary. In general, a standard steel sheet may have a thickness tolerance ranging from +/- 0.001 inches to +/- 0.010 inches. This implies that the actual thickness of the sheet can fall within these tolerances. The determination of the tolerance level is influenced by factors including the manufacturing process, the intended use of the sheet, and the desired level of precision. It is worth mentioning that certain industries or applications may necessitate more precise tolerances, particularly when dimensional accuracy is of utmost importance.

- Q: What are the different sheet metal rolling techniques for steel sheets?

- There are several sheet metal rolling techniques that are commonly used for steel sheets. These techniques include hot rolling, cold rolling, and roll forming. Hot rolling is a process in which steel sheets are heated above their recrystallization temperature and then passed through a series of rollers to reduce their thickness. This technique is commonly used to produce steel sheets with a consistent and uniform thickness. The hot rolling process also improves the mechanical properties of the steel, making it stronger and more ductile. Cold rolling, on the other hand, is a technique in which steel sheets are passed through rollers at room temperature. This process is used to produce thinner and smoother steel sheets with a higher degree of dimensional accuracy. Cold-rolled steel sheets are often used in applications that require a high-quality surface finish, such as automotive body panels and appliances. Roll forming is a continuous bending process in which a long strip of steel is passed through a series of rollers to gradually shape it into a desired profile. This technique is commonly used to produce steel sheets with complex shapes and profiles, such as corrugated roofing sheets or C-channel beams. Roll forming offers excellent precision and repeatability, making it a popular choice for producing large quantities of steel sheets with consistent dimensions. Overall, the choice of sheet metal rolling technique depends on the specific requirements of the application. Hot rolling is ideal for producing steel sheets with a uniform thickness and improved mechanical properties. Cold rolling is preferred for applications that require a high-quality surface finish and dimensional accuracy. Roll forming is suitable for creating steel sheets with complex shapes and profiles.

- Q: Can steel sheets be used for playground equipment?

- Yes, steel sheets can be used for playground equipment. Steel is a strong and durable material that can withstand heavy use and adverse weather conditions, making it suitable for playground equipment such as slides, climbers, and swing sets. Additionally, steel sheets can be shaped and welded into various designs, providing versatility in creating innovative and engaging playground structures.

- Q: How are steel sheets joined together?

- Steel sheets can be joined together using various methods, including welding, bolting, riveting, and adhesive bonding, depending on the specific application and desired strength of the joint.

- Q: Are the steel sheets resistant to impact or bending?

- In general, steel sheets display resistance to both impact and bending. Steel possesses exceptional strength and durability, rendering it less susceptible to external forces like impacts or bending. This is attributed to the material's capacity to absorb and disperse applied energy, leading to minimal deformation or harm. Nevertheless, the extent of resistance to impact and bending may fluctuate based on factors such as sheet thickness, steel type, and any supplementary treatments or coatings that have been applied.

- Q: How are steel sheets protected during transportation by sea?

- To ensure the safety and prevent damage of steel sheets during transportation by sea, various measures are taken. One commonly used method involves applying a protective coating to the sheets. This coating acts as a barrier against moisture and saltwater, which are the main culprits behind corrosion during sea transportation. The coating can be a temporary solution, such as a layer of oil or wax, or a more permanent option, such as a layer of paint or zinc. Moreover, steel sheets are often bundled or placed in shipping containers for added protection. These bundles are secured with straps or wires to prevent movement and potential damage in rough sea conditions. The shipping containers themselves are designed to withstand the challenges of sea transportation and shield the steel sheets from exposure to the elements. Additionally, the sheets may be wrapped in plastic or other waterproof materials to provide an extra layer of defense against moisture. This helps prevent direct contact with seawater or rain, thus reducing the risk of corrosion. During the loading and unloading processes, proper handling techniques are employed to minimize the risk of damage. Cranes or forklifts are carefully used to lift and move the steel sheets, ensuring that they are not dropped or subjected to excessive force that could cause dents or bends. Overall, a combination of protective coatings, secure packaging, and proper handling techniques is utilized to safeguard steel sheets during sea transportation. This reduces the likelihood of damage and ensures that they reach their destination in optimal condition.

- Q: How are steel sheets protected against rusting?

- Steel sheets are protected against rusting through a process called corrosion protection. There are several methods used to protect steel sheets from rust, including: 1. Galvanization: This process involves coating the steel sheets with a layer of zinc. Zinc acts as a sacrificial anode, meaning it corrodes in place of the steel when exposed to moisture or oxygen. This creates a barrier that protects the steel from rusting. 2. Painting: Applying a layer of paint to steel sheets acts as a protective barrier against moisture and oxygen. The paint creates a physical barrier that prevents these elements from coming into contact with the steel, thus reducing the risk of rust formation. 3. Powder coating: Powder coating involves applying a dry powder to the steel sheets and then heating it to form a protective layer. The powder melts and fuses into a smooth coating, providing excellent resistance to rust and corrosion. 4. Electroplating: This method involves immersing the steel sheets in a bath containing a metal coating solution, such as zinc or chromium. An electric current is then passed through the bath, causing the metal coating to bond with the steel. This electroplated layer acts as a protective barrier against rust. 5. Phosphating: Phosphating is a chemical process where a layer of zinc or manganese phosphate is deposited on the steel sheets. This layer enhances the adhesion of paint or other coatings, providing a corrosion-resistant surface. These methods are commonly used in various industries to protect steel sheets from rusting. The specific method chosen depends on factors such as cost, durability requirements, and the environment in which the steel sheets will be used.

- Q: What is the maximum size of the steel sheets available?

- The specific supplier or manufacturer determines the maximum size of available steel sheets, which can vary. Generally, steel sheets come in a variety of sizes, ranging from 36 inches to 72 inches in width, and 96 inches to 240 inches in length. However, it should be noted that these dimensions may differ depending on the supplier's capabilities and the customer's specific requirements. Therefore, it is recommended to directly contact a supplier or manufacturer for information regarding the largest size of steel sheets they can offer.

- Q: What are the benefits of using pre-painted steel sheets?

- There are several benefits of using pre-painted steel sheets. Firstly, they offer a wide range of colors and finishes, allowing for greater design flexibility. Secondly, pre-painted steel sheets are highly resistant to corrosion, providing long-lasting durability. Additionally, they require minimal maintenance, as the paint coating acts as a protective layer against damage and weathering. Furthermore, pre-painted steel sheets are easy to install and can be used in various applications, including roofing, siding, and construction. Overall, their aesthetic appeal, durability, and low maintenance requirements make them a preferred choice in many industries.

- Q: What is the typical load-bearing capacity of a steel sheet?

- The typical load-bearing capacity of a steel sheet can vary depending on its thickness, size, and composition. However, steel sheets generally have high strength and can typically bear heavy loads ranging from several hundred to several thousand pounds per square inch.

Send your message to us

304 Stainless steel plates from okorder.com

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m.t.

- Supply Capability:

- 20000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords