FRP Roofing Panel - Colorful Roofing Metal Sheet

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 200 m

- Supply Capability:

- 20000 m/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

PRODUCT DESCRIPTION

Fiberglass corrugated sheet is usually used in construction site as protecting facility. It is dagarous for workers in building site since you never know if there is something hard drop down from the high area. So corrugated sheet is installed for preventing the stuff dropping down to hurt people.

FEATURES

1) The fiberglass content of new generation greenhouse panel has been improved by 18.3%.

2) Weather resistant and Self-clean ability.

3) Excellent yellowness resistance.

4) Strong impact resistant and low bending rate.

5)Withstand extreme temperature from -38 degree to +110 degree for a long time

6) Aging resistant: specified F4 film added on surface and gel coat makes it endurable for long.

7) More strengthened, safer, cleaner and more economical greenhouse panel.

8) Mainly serve the big factory, warehouse, super markets and other steel-structured project.

SPECIFICATIONS

| Items | Date |

| Tensile Strength | 122.8Mpa |

| Tensile Modulus | 8610Mpa |

| Flexural Strength | 219.9mPA |

| Flexural Modulus | 8210Mpa |

| Barcol Hardness | 47 |

| Izod Impact | 80.4kj/m2 |

| Thermal Expansivity | 2.4X10-5 °C-1 |

| Distortion Termperature | >230°C |

| Water Absorption | 0.16%/24hrs@25°C |

| Gravity | 1.5g/cm3-1.9g/cm3 |

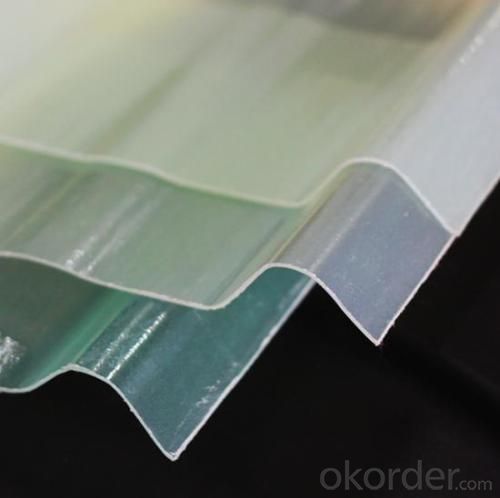

PICTURES

- Q: Are FRP roofing panels available in different thicknesses?

- FRP roofing panels can be found in various thicknesses, allowing for customization based on project or application needs. The thickness of these panels varies between 0.8mm and 3mm, with the possibility of thicker options for specific purposes. The decision on thickness often relies on factors like desired durability, insulation properties, and load-bearing capacity. It is crucial to seek guidance from professionals or suppliers to identify the ideal thickness for your FRP roofing panel requirements.

- Q: Are FRP roofing panels resistant to fading or discoloration?

- Yes, FRP roofing panels are generally resistant to fading or discoloration due to their durable construction and protective coatings.

- Q: Can FRP roofing panels be used in hospitals or healthcare facilities?

- Yes, FRP roofing panels can be used in hospitals or healthcare facilities. FRP (Fiberglass Reinforced Plastic) roofing panels are durable, lightweight, and resistant to corrosion, making them suitable for such environments. They are also easy to clean and maintain, helping to maintain a hygienic and sterile environment in healthcare facilities. Additionally, FRP panels offer good thermal insulation properties and can be designed to meet specific fire safety and acoustic requirements, making them a practical choice for hospitals and healthcare facilities.

- Q: Can FRP roofing panels be installed on both residential and commercial pergolas?

- FRP roofing panels are suitable for installation on both residential and commercial pergolas. They are a multipurpose roofing material that can be utilized in a variety of settings, including pergolas. Lightweight, durable, and resistant to weather elements such as UV radiation, rain, and wind, FRP panels offer several advantages. Whether it is a residential or commercial pergola, FRP panels bring numerous benefits. They are easy to install, resulting in reduced labor and time costs. Furthermore, homeowners or businesses can choose from a range of profiles, colors, and patterns to match their preferences or branding. In addition, FRP roofing panels allow for excellent natural light transmission, reducing the need for artificial lighting during daylight hours. This feature proves especially advantageous for commercial pergolas used for outdoor seating areas or events, creating a pleasant ambiance for customers. In summary, FRP roofing panels are an excellent choice for both residential and commercial pergolas due to their durability, aesthetic appeal, and ease of installation.

- Q: Are FRP roofing panels suitable for museums?

- FRP (Fiberglass Reinforced Plastic) roofing panels can be suitable for museums, depending on the specific requirements and conditions of the museum. One of the key advantages of FRP roofing panels is their durability. They are highly resistant to UV radiation, corrosion, and impact, making them ideal for protecting against weather elements. This durability ensures that the panels can maintain their structural integrity over time, reducing the need for frequent repairs or replacements. Additionally, FRP roofing panels are lightweight, which can be beneficial for museums with older or historic buildings that may have limitations on the weight-bearing capacity of the roof. The lightweight nature of FRP panels also makes installation easier and more cost-effective. Furthermore, FRP panels can provide excellent thermal insulation, preventing heat transfer and maintaining a stable temperature inside the museum. This is particularly important for museums that house delicate artifacts or artwork that can be sensitive to temperature fluctuations. However, it is crucial to consider the specific needs of the museum before deciding on FRP roofing panels. Depending on the nature of the museum and its collections, additional measures may be necessary to control factors such as lighting, humidity, and air quality. In such cases, it may be necessary to incorporate additional roofing materials or systems to meet these requirements. Overall, FRP roofing panels can be a suitable choice for museums, especially if durability, lightweight construction, and thermal insulation are key considerations. However, it is essential to evaluate the specific needs and conditions of the museum before making a final decision.

- Q: Can FRP roofing panels be used for awnings or canopies?

- Yes, FRP roofing panels can be used for awnings or canopies. FRP (Fiberglass Reinforced Plastic) is a durable and lightweight material that is commonly used for roofing applications. Its strength and weather resistance make it suitable for creating awnings or canopies to provide shade and protect against the elements.

- Q: Can FRP roofing panels be used in areas with frequent lightning strikes?

- Yes, FRP roofing panels can be used in areas with frequent lightning strikes as they are non-conductive and do not attract or conduct electricity. This makes them a safe choice for such areas.

- Q: Are FRP roofing panels suitable for restaurants?

- Yes, FRP roofing panels are suitable for restaurants. FRP (Fiberglass Reinforced Plastic) panels are known for their durability, resistance to corrosion, and ability to withstand harsh weather conditions. These qualities make them an excellent choice for restaurant roofs, as they can effectively protect the building from moisture, UV rays, and other environmental factors. Additionally, FRP panels are lightweight, easy to install, and offer good insulation properties, which can contribute to energy savings. Overall, FRP roofing panels are a reliable and cost-effective option for restaurants seeking a long-lasting and low-maintenance roofing solution.

- Q: Are FRP roofing panels suitable for greenhouses?

- Yes, FRP roofing panels are suitable for greenhouses. FRP (Fiberglass Reinforced Panels) offer excellent durability, light transmission, and insulation properties, making them a popular choice for greenhouse roofing. They are resistant to UV rays, weathering, and corrosion, ensuring long-term performance. Additionally, FRP panels are lightweight, easy to install, and cost-effective, making them an ideal option for greenhouse construction.

- Q: Can FRP roofing panels withstand high winds?

- Yes, FRP (Fiberglass Reinforced Plastic) roofing panels are designed to withstand high winds. These panels are made from a combination of fiberglass and resin, which provides them with excellent strength and durability. They are engineered to be resistant to bending, warping, and cracking, even in extreme weather conditions such as high winds. FRP roofing panels are often used in areas prone to hurricanes and strong windstorms, where they have proven to be highly effective in protecting buildings against wind damage. They are designed with interlocking mechanisms that provide extra stability and prevent them from being lifted or torn off by strong winds. Additionally, FRP roofing panels are lightweight compared to other roofing materials such as metal or concrete. This light weight reduces the risk of structural damage during high winds as it places less stress on the building's framework. However, it is important to note that the ability of FRP roofing panels to withstand high winds may also depend on other factors such as the installation method, the condition of the roof, and the specific wind load requirements of the area. It is recommended to consult with a professional roofing contractor or follow the manufacturer's guidelines to ensure proper installation and to determine the specific wind resistance capabilities of FRP roofing panels in your particular situation.

Send your message to us

FRP Roofing Panel - Colorful Roofing Metal Sheet

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 200 m

- Supply Capability:

- 20000 m/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords