FRP Roofing Panel for Houses - Corrugated Metal Roof Sheet Manufacturing

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 200 m

- Supply Capability:

- 50000 m/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

PRODUCT DESCRIPTION

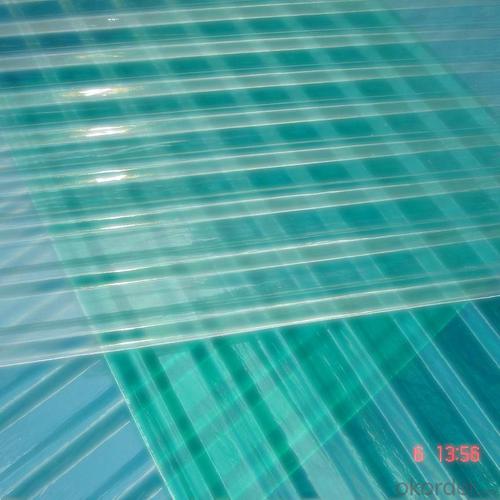

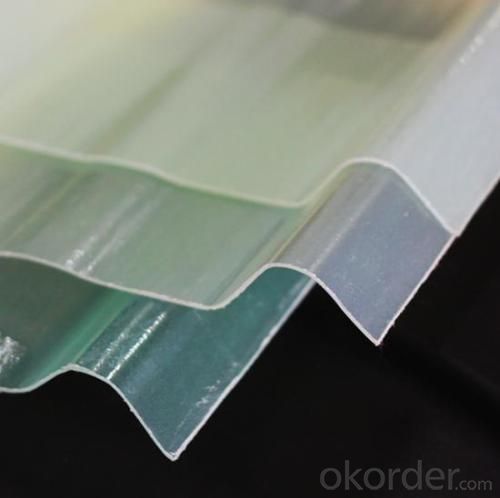

FRP GRP Fiberglass Glassfiber Corrugated Roofing is a patent of our company, not like other FRP products, it is produced without yarn, instead, we use mat only. Therefore, the corrugated sheet is more strong in both horizontal and vertical direction.

Cold rolled sheet has superb sheet shape and surface quality with good flatness and surface finish. The surface of the cold sheet is clean and bright and easy for coating. The varieties of cold rolled sheet are widely used in galvanized substrates, home appliances, tubing, automobiles, building, enamels and other industries.

FEATURES

a. anti-corrosion, non-rusty

b. lightweight and high strength

c. anti-flammable

d. anti-fatigue

e. anti-slippery and safety

f. anti-ageing

g. easy to installation and maintenance

h. excellent electromagnetism property

SPECIFICATION

| Products Name | Manufacture corrugated metal roof / zinc roof / roofing sheet for houses |

THICKNESS | 0.14-0.5MM |

WIDTH | 765MM-->665MM 900MM-->800MM 1000MM-->900MM |

ALUZINC | ALUZINC ROOFING CAN BE SUPPLIED. |

MATERIAL | SGCC,DC51D,DX51D,DX52D |

SPANGLE | ZERO, REGULAR, NORMAL,BIG SPANGLE. |

SURFACT TREATMENT | CHROMATED, OILED, NON-OILED, DRY. |

HARDNESS | SOFT, HARD, FULL HARD. |

PICTURES

- Q: Can FRP roofing panels be used for covered walkways in airports or transportation hubs?

- Covered walkways in airports or transportation hubs can utilize FRP roofing panels. These panels, made of fiberglass reinforced plastic, are popular due to their durability, lightweight nature, and ability to withstand various weather conditions. They are resistant to UV rays, corrosion, and impact, making them suitable for high-traffic areas. Moreover, FRP roofing panels have a long lifespan and require minimal maintenance, reducing the need for frequent replacements. They come in various colors and designs, allowing for customization and integration with the surrounding architecture. In addition, these panels provide excellent light transmission, allowing natural light to enhance visibility in the covered walkways and reducing the reliance on artificial lighting during the day. This contributes to energy efficiency and cost savings. In conclusion, FRP roofing panels are a reliable and practical choice for covered walkways in airports or transportation hubs, offering durability, low maintenance, aesthetic appeal, and energy efficiency benefits.

- Q: Are FRP roofing panels suitable for DIY installation?

- Yes, FRP (Fiberglass Reinforced Plastic) roofing panels can be suitable for DIY installation depending on the level of experience and skill of the individual. FRP roofing panels are lightweight, durable, and easy to handle, making them a popular choice for do-it-yourself projects. However, it is important to note that proper installation techniques and safety precautions should be followed to ensure a successful installation. This may include wearing appropriate protective gear, using the correct tools, and following the manufacturer's instructions. Additionally, it is recommended to consult with a professional or seek advice from reputable sources to ensure that the installation is done correctly and meets local building codes.

- Q: Do FRP roofing panels require a specific type of gutter system?

- Yes, FRP (Fiberglass Reinforced Plastic) roofing panels do require a specific type of gutter system. The choice of gutter system for FRP roofing panels depends on the specific characteristics of the panels and the building structure. FRP roofing panels have unique properties such as lightweight, durability, and resistance to corrosion which makes them an attractive choice for many roofing applications. However, they also have different thermal expansion and contraction rates compared to traditional roofing materials like metal or asphalt. To accommodate the thermal movement of FRP roofing panels, it is recommended to use a gutter system that allows for expansion and contraction. This usually involves using gutter hangers or brackets that allow for movement and flexibility. Additionally, it is important to ensure that the gutter system is properly installed and securely fastened to the building structure to prevent any potential damage caused by wind, rain, or snow loads. It is always advisable to consult with a roofing professional or manufacturer's guidelines to determine the specific type of gutter system that is suitable for FRP roofing panels. They can provide expert advice on the best gutter system that will ensure proper drainage and protection for your FRP roofing panels, thereby prolonging their lifespan and maintaining their performance.

- Q: What is the cost of FRP roofing panels?

- Various factors such as panel size, thickness, quality, and brand contribute to the variable cost of FRP (Fiberglass Reinforced Plastic) roofing panels. The price per square foot typically falls between $2 and $8. Nonetheless, it is crucial to acknowledge that this is merely a rough approximation and the actual cost can vary considerably. For accurate pricing information based on specific needs and customization options, it is advisable to directly reach out to suppliers or manufacturers. Furthermore, it is important to take into account installation expenses, which can fluctuate depending on the project's complexity and required labor.

- Q: Are FRP roofing panels resistant to warping or bowing?

- Yes, FRP (Fiberglass Reinforced Plastic) roofing panels are highly resistant to warping or bowing. The unique composition of FRP panels, which consists of a reinforced fiberglass layer embedded in a plastic resin matrix, provides excellent structural integrity and dimensional stability. This construction makes FRP panels highly resistant to the effects of temperature changes, moisture, and UV exposure, which are common causes of warping or bowing in other roofing materials. Furthermore, FRP panels are designed to withstand heavy loads and resist flexing. Their high strength-to-weight ratio ensures that they maintain their shape and structural integrity over time, even under significant external pressures. As a result, FRP roofing panels are ideal for applications where flatness and stability are essential, such as in industrial buildings, agricultural structures, or commercial facilities. However, it is important to note that extreme conditions or poor installation practices can potentially lead to some degree of warping or bowing in FRP roofing panels. Therefore, it is crucial to follow manufacturer guidelines and specifications during installation to ensure optimal performance and minimize any potential issues.

- Q: Are FRP roofing panels compatible with different roofing adhesives?

- Generally, FRP roofing panels can be used with various types of roofing adhesives. However, it is essential to ensure that the adhesive being used is appropriate for FRP panels. FRP panels are commonly employed in roofing applications due to their durability, strength, and ability to withstand different weather conditions. There are different adhesive options available, including epoxy, polyurethane, and silicone adhesives. Before applying any adhesive to FRP roofing panels, it is crucial to carefully read and follow the manufacturer's instructions and recommendations. The manufacturer typically provides guidance on which adhesive types are compatible with their specific FRP panels. By adhering to these recommendations, a proper bond can be achieved between the panels and the roofing substrate. Furthermore, it is important to consider the environmental conditions in which the roofing panels will be installed. Extreme temperatures, humidity, and exposure to UV rays can impact the adhesive's performance. Therefore, it is crucial to select an adhesive that is specifically designed to withstand the particular environmental conditions of the roofing project. To summarize, FRP roofing panels can be used with different roofing adhesives, but it is vital to follow the manufacturer's recommendations and choose an adhesive that is suitable for FRP panels and the specific environmental conditions of the project.

- Q: Are FRP roofing panels resistant to pests?

- Generally, pests are not attracted to FRP (Fiberglass Reinforced Plastic) roofing panels. This is because the materials used in FRP panels, such as fiberglass and plastic, do not appeal to insects or rodents. Unlike wood or asphalt, which can serve as a food source or nesting place for pests, FRP panels do not provide such opportunities. Furthermore, FRP panels are typically installed without any gaps or openings that pests could use to gain access. However, it is important to note that while FRP panels are resistant to pests, they are not completely immune. In rare cases, certain pests may still be able to cause damage to FRP panels. Nevertheless, overall, FRP panels offer a higher level of protection compared to other roofing materials.

- Q: Are FRP roofing panels suitable for residential communities?

- Yes, FRP (Fiberglass Reinforced Plastic) roofing panels can be suitable for residential communities. FRP roofing panels offer several advantages that make them a viable option for residential use. Firstly, FRP panels are lightweight, making them easier to install and transport compared to other roofing materials. This can significantly reduce installation time and costs. Secondly, FRP roofing panels are highly durable and resistant to various weather conditions, including extreme temperatures, UV rays, and moisture. This durability ensures that the roof can withstand the elements and remain intact for an extended period, reducing the need for frequent repairs or replacements. Additionally, FRP panels are fire-resistant, which is a crucial safety feature for residential communities. This fire resistance can help prevent the spread of fire in case of accidents or emergencies, providing an added layer of protection for residents. Moreover, FRP roofing panels are available in a range of colors and designs, allowing homeowners to choose a style that matches the aesthetics of their community. This versatility ensures that FRP panels can seamlessly blend into the overall architectural design of residential areas. Lastly, FRP roofing panels are cost-effective compared to other roofing materials, such as metal or asphalt shingles. The initial installation costs are often lower, and the long-term maintenance expenses are minimal due to the material's durability. This affordability can be particularly beneficial for residential communities with budget constraints or homeowners looking to reduce their overall roofing expenses. Overall, FRP roofing panels are a suitable option for residential communities due to their lightweight nature, durability, fire resistance, aesthetic versatility, and cost-effectiveness. However, it is essential to consult with roofing professionals and consider the specific needs and requirements of the community before making a final decision.

- Q: Can FRP roofing panels be used for noise insulation in buildings?

- Yes, FRP (Fiberglass Reinforced Plastic) roofing panels can be used for noise insulation in buildings. Due to their composition of multiple layers of fiberglass, FRP roofing panels provide effective sound-absorption properties. They can help reduce noise levels by absorbing and dampening sound vibrations, making them a suitable choice for noise insulation in various building applications.

- Q: Are FRP roofing panels resistant to bird nesting or damage?

- FRP roofing panels, also known as Fiberglass Reinforced Plastic panels, are generally resistant to bird nesting and damage. The smooth surface of FRP panels makes it difficult for birds to build nests as they cannot grip on to the material easily. Additionally, the durability and strength of FRP panels make it less prone to damage caused by birds. However, it is worth noting that no roofing material can be completely immune to bird activity. Persistent birds may still attempt to nest on FRP panels, especially in areas where they have easy access. In such cases, it is recommended to take preventive measures like installing bird deterrents or maintaining regular cleaning to discourage bird nesting.

Send your message to us

FRP Roofing Panel for Houses - Corrugated Metal Roof Sheet Manufacturing

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 200 m

- Supply Capability:

- 50000 m/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords