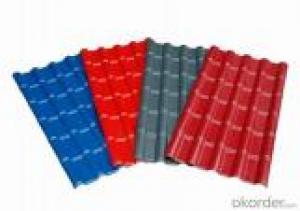

Colorful FRP Roofing Sheet

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specifications of Colorful FRP Roofing Sheet

FRP Sheet made by serial machinery of FRP sheet have the advantages of smooth surface, even thickness, high impact strength, good weather resistance as well as high productivity. It is the best materials for the surface panels of top grade refrigeration vehicles for its excellent properties of heat and moisture insulaiton.

Thickness:0.8mm、1.0mm、1.2mm、1.5mm、2.0mm、2.5mm、3.0mm;

Width:1000mm、1200mm;

Color:Clear/Lake Blue/Sky Blue/Light Green/ Opal;

Length:30m/rolling

Applications of Colorful FRP Roofing Sheet

They are applied to steel structure workshops, warehouses, weather sheds, car parks, weather corridors, lighting sheds, sun sheds,

greenhouses, etc. They are the ideal materials for the choices of enterprises and institutions.

The necessary characters of high quality FRP Corrugated Lighting Sheet:

1. small air bibbles

2. no bubbles

3. anti-aging resin

4. high property upper film(or gelatum)

5. high quality non-alkali fiber-glass

6. consistent high light transmission

7. high chemistry corrosion resistance

8. high anti-ultraviolet property

9. even thickness

Package& Delivery of Colorful FRP Roofing Sheet

Wooden pallet,according to custom requires.

Properties of Colorful FRP Roofing Sheet

Light transmission

The light transmission of FRP Corrugated Lighting Sheet is between 60-85%. Light through FRP lighting sheet scatters and is mild. It will not form a light band so as to make the indoor brighter.

Weather resistance

The 23μm anti-aging film from Dupont covering on the surface of FRP sheet improves its property of weather resistance. The anti- ultraviolet adsorbing agent mixing in the raw materials absorbs 99.9% of ultraviolet ray of the visible light transmitted through the FRP sheets.This UV protection will help to prevent the dissolution and discoloration of the materials. The unique technology used in FRP Corrugated Lighting Sheet makes the life span of the sheet up to over 15 years, probably 20 years ( a ten-year warranty is supplied).

Impact resistance

The strengthening fiber-glass materials criss-cross the structure of the products,which helps to improve the impact resistance of FRP sheet. When impacted by spalls or hails, they are hardly broken.

Corrosion resistance

The products resist various acids, alkalis and peroxides, especially suitable for application in the coastal areas and corrosive places.

Temperature performance

FRP Corrugated Lighting Sheet is a kind of hot solid high polymer materials. It is designed for normal use in temperatures from - 40℃ to120℃.

Temperature insulation

The coefficient of heat-conduction of FRP Corrugated Lighting Sheet is 0.18kcat / mhr℃ , only 1/4 of the glass. That is why it has a good property of temperature insulation.

Fire-retardant

Fire-retardant the fire-retardant of FRP Corrugated Lighting Sheet is divided into ordinary gradeⅠ and gradeⅡ. The oxygen index of the gradeⅠof fire retardant is ≥32, the grade retardant is ≥26. It meets the standards of the fire brigade department.

Heat stability

FRP Corrugated Lighting Sheet is a kind strengthening plastic of hot solid fiber-glass . Its coefficient of heat expansion is 2.2 x 10-5mm/mm/℃, only 2 times of metal materials. For this reason, when it matches with a metal sheet, the displacement is relatively small, not easy to leak.

- Q: Synthetic resin tile profile, synthetic resin tile specifications, synthetic resin tile installed?

- Is the use of modern technology with antique-style design and construction It is divided into two layers: the last for the anti-aging layer, is 02mm thick ASA resin material covering synthesis The lower layer for the impact, corrosion-resistant, is 28mm thick PVC chemical materials and other auxiliary materials composed of co-extrusion synthesis ASA (English name: AcrylonitrileStyreneacrylatecopolymer engineering plastics is acrylic rubber and acrylonitrile, styrene graft copolymer) PVC that is polyvinyl chloride English referred to as PVC (Polyvinylchloridepolymer = PVC molecular structure), is the role of vinyl chloride in the initiator under the polymerization of thermoplastic resin Reference materials can be under Google: Yiming synthetic resin tile

- Q: Resin composite materials and fiberglass compared to the seismic, mechanical strength, paint adhesion What are the advantages and disadvantages? Do not copy and paste

- Resin Synthetic material is a synthetic polymer of a class of polymers

- Q: I heard that synthetic resin tile very environmentally friendly, how an environmental law? How is it done?

- Hello, synthetic resin tile does not contain asbestos and radioactive elements, and can be recycled

- Q: Synthetic resin tile for flat to slope, do not wild, mobile housing, garden loft where the advantages?

- In the natural environment with extraordinary durability, it even long-term exposure to ultraviolet light, moisture, heat, cold harsh conditions, can still maintain its color stability 2 Excellent corrosion resistance: synthetic resin tile can be long-term resistance to acid, alkali, salt and other chemical substances corrosion Experiments show that: salt, alkali and 60% of the following acid soak for 24 hours without chemical reaction Very suitable for acid rain-prone areas and coastal areas, the effect is particularly significant 3 Thermal insulation performance: synthetic resin tile thermal conductivity of 0325w / mk, about 1/3 of the clay tile, cement tile 1/ 05mm thick color steel tile 1/200 Therefore, without considering the case of insulation layer, the synthetic resin tile insulation performance can still be the best 4 Self-cleaning performance: synthetic resin tile surface is dense and smooth, with "lotus effect", itself is not easy to adsorb dust, once the rain washed as clean, tile surface dirt was washed after the rain does not appear spotted color phenomenon 5 Excellent waterproof performance: Synthetic resin tile used in the high weather resistance of the resin itself is dense and non-absorbent, there is no problem of microporous water seepage Product width than the traditional tile width of 45%, less roof seams, synthetic resin tile than the traditional tile waterproof performance greatly improved 6 Installation fast: synthetic resin tile effective width 800mm, pavement high efficiency; light weight, easy loading and unloading; installation accessories complete 7 Green: synthetic resin tile does not contain asbestos and radioactive elements, and recyclable, in full compliance with green environmental requirements Kebao building materials: telephone one hundred zero zero qi three one II zero qi

- Q: My house is a resin tile, but the resin tile can only last three decades, three years later how to do it? It makes me depressed

- All the materials are the number of years, the use of commercial housing 40 to 70 years, the scope of application of resin tile is mainly used in flat slope, mobile housing, villas, antique buildings, garden pavilions and other roof areas

- Q: 3.0 mm thickness of the synthetic resin tile weight is different? The price is not the same, the heavier the better or the lighter the better? Please explain why, thank you

- High-quality synthetic resin tile weight range: high-quality synthetic resin tile density of about 1

- Q: Need anti-corrosion synthetic resin tile, who can provide anti-corrosion synthetic resin tile information to me, to be clear Oh

- 0mm anti-corrosion synthetic resin tile: according to the multiples of custom-made anti-corrosion synthetic resin tile color: jujube ? brick red ? gray ? blue ? green anti-corrosion synthetic resin tile: : 880mm; effective width: 800mm anti-corrosion synthetic resin tile total width: 1050mm; effective width: 960mm anti-corrosion synthetic resin Wavelength: 160mm; ? wave height; 30mm anti-corrosion synthetic resin tile pitch; 220mm anti-corrosion synthetic resin tile thickness 3

- Q: Why is the price of synthetic resin tile 3.0 cheaper than 2.0?

- High-quality synthetic resin tile weight range High-quality synthetic resin tile density of about 1

- Q: Synthetic resin tile, is the type of building materials that are building materials? Where are they used?

- Synthetic resin tile, is a plastic material of building materials

- Q: Synthetic resin tile can be used in what kind of place, residential can use it

- The house is fully available with synthetic resin tiles, which is a very good material

Send your message to us

Colorful FRP Roofing Sheet

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords