Corrugated Plastic Roofing Sheet, Fiber FRP Transparent Roof Pane

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m

- Supply Capability:

- 50000 m/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

PRODUCT DESCRIPTION

FRP Roofing Sheet are widely used in the field of industrial plants, warehouses, greenhouses, stations, docks, airports, sports buildings, commercial buildings, steel structures and other lighting areas. FRP is glass fiber and one or several thermosetting or thermoplastic resin composite material, such as phenolic resin, epoxy resin, polyester resin, polyimide resin. Glass fiber reinforced glass fiber that is the early 20th century, the development of a new composite material, it has a light weight, high strength, corrosion, insulation, insulation, noise and many other advantages.

FEATURES

1. Weatherability: In the temperature range of -40 ℃ - 120 ℃ to maintain stable performance;

2. Low thermal conductivity & good insulation performance;

3. Non-toxic, non-asbestos, etc., in line with world health standards;

4. No moss & prevent microbial growth;

5. High impact and resistant to strong wind;

6. Safe and reliable, Not combustion-supporting in open fire;

7. Corrosion resistance, suitable for chemical workshop roof, such as fertilizer plants, electroplating factory

SPECIFICATIONS

Item | Description | ||

Material | FRP, ASA, PVC | ||

Thickness | 1.0mm - 3.0mm | ||

Color | Clear, milk white, blue, green, red | ||

Type | 475, 666, 760, 820, 840, 860, 900, 950, 980, 1050, can be customized | ||

Shelf life | 15 years | ||

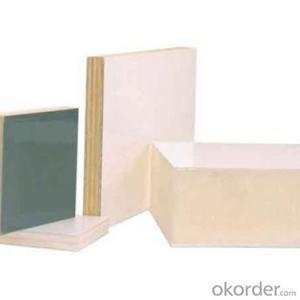

PICTURES

- Q: Are FRP roofing panels environmentally friendly?

- Yes, FRP roofing panels are considered environmentally friendly. They are made from recycled materials and are highly durable, which means they have a long lifespan and reduce the need for frequent replacements. Additionally, FRP roofing panels are energy-efficient and can help reduce energy consumption by providing better insulation, thus reducing the reliance on heating and cooling systems. Overall, FRP roofing panels contribute to a greener and more sustainable environment.

- Q: Can FRP roofing panels be installed on mobile homes?

- Yes, FRP (Fiberglass Reinforced Plastic) roofing panels can be installed on mobile homes. FRP panels are lightweight, durable, and provide excellent protection against weather elements. They are also easy to install and can be a cost-effective roofing solution for mobile homes.

- Q: Are FRP roofing panels resistant to vandalism or graffiti?

- FRP roofing panels, also called fiberglass reinforced plastic panels, provide a certain level of protection against vandalism and graffiti. Although they are generally more resistant than other roofing materials like metal or asphalt, they are not completely immune to such acts. The sleek surface of FRP roofing panels makes it more challenging for vandals to spray paint or draw graffiti on them. Moreover, the panels are typically made of sturdy materials that can withstand impact and scratching to some extent. This makes it more difficult for individuals to intentionally damage or deface the panels. Nevertheless, it is vital to acknowledge that FRP roofing panels can still be vulnerable to vandalism and graffiti, particularly if targeted by determined individuals. Factors such as the panels' location and the level of security in the area can also influence the likelihood of such incidents occurring. To enhance the resistance of FRP roofing panels to vandalism or graffiti, additional measures can be taken. For example, applying an anti-graffiti coating or film on the surface of the panels can serve as a protective barrier, facilitating the removal of any unwanted markings. Surveillance systems and proper lighting in the vicinity of the panels can also discourage vandals. In conclusion, while FRP roofing panels offer a certain level of resistance to vandalism and graffiti due to their sleek surface and durable materials, it is not guaranteed that they will remain completely untouched. Implementing appropriate preventive measures and security measures can further enhance their resistance to such acts.

- Q: Do FRP roofing panels require any specific type of sealant or adhesive for installation?

- To properly install FRP (Fiberglass Reinforced Plastic) roofing panels, a specific sealant or adhesive is necessary. It is vital to choose a sealant or adhesive that is designed specifically for bonding FRP panels, ensuring a secure and proper installation. A commonly utilized adhesive for FRP roofing panels is a high-strength polyurethane adhesive. This adhesive is renowned for its exceptional bonding properties and its ability to withstand harsh weather conditions. It establishes a strong and durable bond between the FRP panels and the underlying surface, guaranteeing a long-lasting installation. Moreover, it is advisable to employ a sealant that is compatible with FRP panels. This helps create a watertight seal between the panels, preventing any moisture or water infiltration that could potentially cause leaks or damage. When selecting and applying the sealant or adhesive, it is crucial to carefully read and adhere to the manufacturer's instructions. This ensures the correct product is utilized and applied in the appropriate manner, optimizing its performance. In conclusion, the correct sealant or adhesive is pivotal for the successful installation of FRP roofing panels. It establishes a secure and durable bond, as well as a watertight seal, providing protection against the elements and extending the roof's lifespan.

- Q: What is the expected lifespan of FRP roofing panels?

- The expected lifespan of FRP roofing panels can vary depending on various factors such as the quality of the panels, the installation process, and the environmental conditions in which they are exposed to. However, on average, FRP roofing panels can have a lifespan of around 20 to 30 years. FRP, also known as fiberglass reinforced plastic, is a durable and lightweight material that is resistant to corrosion, UV radiation, and extreme weather conditions. This makes it a popular choice for roofing applications, especially in areas with harsh climates. Proper installation and regular maintenance are crucial for maximizing the lifespan of FRP roofing panels. Regular inspections and cleaning can help prevent the accumulation of debris, which can deteriorate the panels over time. Additionally, applying a protective coating or sealant can further enhance the longevity of the panels by providing an extra layer of protection against wear and tear. It is important to note that the lifespan of FRP roofing panels can also be influenced by the specific brand or manufacturer. Some manufacturers may offer panels with extended warranties, indicating their confidence in the longevity of their products. Therefore, it is advisable to consult with a reputable supplier or manufacturer to determine the expected lifespan of specific FRP roofing panels before making a purchase.

- Q: Do FRP roofing panels require a specific type of ventilation?

- Yes, FRP roofing panels typically require proper ventilation to prevent moisture buildup and ensure the longevity of the panels.

- Q: Can FRP roofing panels be used for walkways?

- FRP (Fiberglass Reinforced Plastic) roofing panels are primarily designed and recommended for use as roofing material, not for walkways. While they are lightweight, durable, and resistant to certain environmental elements, FRP panels may not be suitable for walkways due to their smooth surface, which can become slippery when wet or icy. Additionally, FRP panels may not have the necessary structural support or load-bearing capacity required for safely accommodating foot traffic. It is crucial to prioritize safety when designing walkways, and it is advisable to choose materials explicitly designed and tested for this purpose, such as non-slip concrete, pavers, or other suitable options.

- Q: Do FRP roofing panels require a specific type of sealant?

- Yes, FRP roofing panels typically require a specific type of sealant that is compatible with the material to ensure proper adhesion and weather resistance.

- Q: Scrap glass fiber reinforced plastic water tank board what to use, where there is recycling?

- Glass fiber reinforced plastic products have no recycling value, they are scrapped, only incineration. Because degradation is difficult.

- Q: Are FRP roofing panels suitable for government buildings?

- Yes, FRP roofing panels are suitable for government buildings. FRP (Fiberglass Reinforced Plastic) roofing panels offer several advantages such as durability, low maintenance, and resistance to various weather conditions. These panels can withstand high winds, hail, and UV rays, ensuring long-term performance and reducing the need for frequent repairs or replacements. Additionally, FRP panels are lightweight, making them easier to install and reducing the load on the building's structure. Considering these benefits, FRP roofing panels can be an excellent choice for government buildings seeking a cost-effective and sustainable roofing solution.

Send your message to us

Corrugated Plastic Roofing Sheet, Fiber FRP Transparent Roof Pane

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m

- Supply Capability:

- 50000 m/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords