FRP Roofing Panel S15 - High Quality FRP Panels

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 100Pcs m.t.

- Supply Capability:

- 1000Pcs m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification of FRP Roofing Panel S15

Thickness:2.0mm

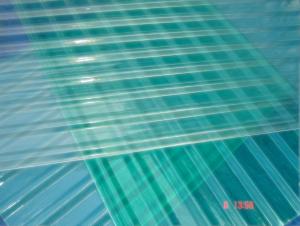

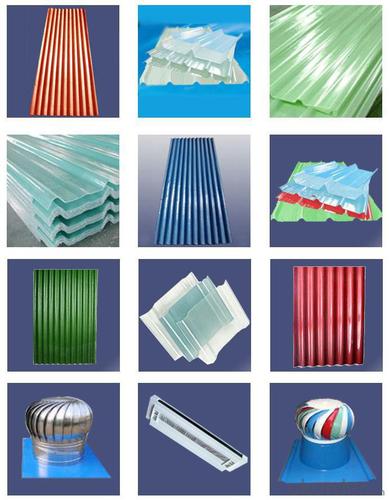

Color:sky blue, dark blue, clear, light green, dark green, opal, etc.Ordinary Wave: 950-237,

Length:No limit but with the consideration of transportation

Features of FRP Roofing Panel S15:

1) The fiberglass content of new generation greenhouse panel has been improved by 18.3%

2) Weather resistant and Self-clean ability

3) Excellent yellowness resistance

4) Strong impact resistant and low bending rate

5)Withstand extreme temperature from -38 degree to +110 degree for a long time

6) Aging resistant: specified F4 film added on surface and gel coat makes it endurable

for long.

7) More strengthened, safer, cleaner and more economical greenhouse panel.

8) Mainly serve the big factory, warehouse, super markets and other steel-structured project.

Packaging & Delivery of FRP Roofing Panel S15:

Packaging Detail: standard packing for export

Delivery Detail:3~7 days

- Q: Can FRP roofing panels be used for agricultural barns or sheds?

- Yes, FRP (Fiberglass Reinforced Plastic) roofing panels can be used for agricultural barns or sheds. FRP panels are lightweight, durable, and resistant to corrosion, making them a suitable choice for agricultural structures. They are also easy to install and maintain, providing a cost-effective roofing solution for barns or sheds in agricultural settings.

- Q: Can FRP roofing panels be used in modular construction?

- Yes, FRP roofing panels can be used in modular construction.

- Q: Are FRP roofing panels suitable for agricultural or farm buildings?

- Yes, FRP roofing panels are suitable for agricultural or farm buildings. They are durable, lightweight, and resistant to corrosion, making them ideal for withstanding the harsh conditions often found in agricultural environments. Additionally, FRP roofing panels offer excellent UV protection, insulation, and are cost-effective, making them a practical choice for farm buildings.

- Q: Do FRP roofing panels require any special certifications or approvals?

- Special certifications or approvals may be necessary for FRP roofing panels, depending on local building codes and regulations. To determine the specific requirements for these panels in your area, it is important to consult with local authorities or building departments. In certain situations, meeting fire safety standards, structural integrity requirements, or other specifications may be necessary to obtain the required certifications or approvals. Compliance with industry standards, such as ASTM International or the International Code Council (ICC), may also be essential. Ensuring that any FRP roofing panels used in construction projects meet the necessary certifications or approvals is crucial for safety, durability, and compliance with applicable regulations.

- Q: Are FRP roofing panels suitable for green building projects?

- Yes, FRP roofing panels are suitable for green building projects. FRP (Fiberglass Reinforced Plastic) panels are lightweight, durable, and have excellent thermal insulation properties. They are also resistant to corrosion and require minimal maintenance, making them an environmentally friendly choice. Additionally, FRP panels are often made from recycled materials and can be recycled themselves, further contributing to sustainable building practices.

- Q: Can FRP roofing panels be used for awnings?

- Yes, FRP roofing panels can be used for awnings. FRP (Fiberglass Reinforced Plastic) panels are lightweight, durable, and weather-resistant, making them a suitable choice for awning applications. They provide protection from the sun, rain, and other elements while offering a range of design options due to their versatile nature.

- Q: Can FRP roofing panels be used for canopies over entrances?

- Yes, FRP (Fiberglass Reinforced Plastic) roofing panels can be used for canopies over entrances. FRP panels are lightweight, durable, and have excellent weather resistance, making them suitable for outdoor applications such as canopies. They can provide protection from the elements and create an inviting and visually appealing entrance. Additionally, FRP panels are available in various colors, textures, and designs, allowing for customization to match the aesthetic requirements of the building or entrance.

- Q: Are FRP roofing panels impact-resistant?

- Yes, FRP (Fiberglass Reinforced Plastic) roofing panels are impact-resistant. The fiberglass reinforcement in these panels makes them highly durable and capable of withstanding impacts from hail, debris, and other external forces without getting damaged easily.

- Q: Are FRP roofing panels suitable for extreme weather conditions?

- Yes, FRP (Fiberglass Reinforced Plastic) roofing panels are well-suited for extreme weather conditions. Due to their durable and weather-resistant properties, FRP panels can withstand high winds, heavy rain, hail, and even extreme temperatures without deteriorating or losing structural integrity. They are UV-resistant, corrosion-resistant, and have excellent thermal insulation properties, making them an ideal choice for areas prone to harsh weather conditions.

- Q: Do FRP roofing panels require regular maintenance?

- The durability and low maintenance requirements of FRP (Fiberglass Reinforced Plastic) roofing panels are well-known. Unlike traditional asphalt or wood roofing materials, FRP panels do not need regular maintenance to ensure their longevity and performance. FRP panels exhibit resistance to UV radiation, moisture, chemicals, and temperature fluctuations, which contribute to their high durability and long-lasting nature. They are also non-corrosive and do not rust or deteriorate over time. This inherent resistance to different elements eliminates the need for routine maintenance tasks like painting, sealing, or applying protective coatings. Moreover, FRP panels have a smooth and non-porous surface, preventing the accumulation of dirt, debris, and organic growth such as moss or algae. Consequently, they do not require frequent cleaning or pressure washing to maintain their appearance and functionality. Nevertheless, it is important to note that while FRP roofing panels do not require regular maintenance, it is advisable to conduct periodic inspections to identify any potential issues or damage that may arise over time. These inspections can ensure that the panels remain in optimal condition and address any minor repairs or replacements if needed. In conclusion, FRP roofing panels are designed to be low maintenance and require minimal attention and upkeep. Their durability, resistance to various elements, and lack of porosity make them an ideal choice for individuals seeking a roofing material that does not demand regular maintenance.

1. Manufacturer Overview

| Location | Shanghai, China |

| Year Established | 1999 |

| Annual Output Value | Above US$ 300,000 |

| Main Markets | Mid East; Eastern Europe; North America |

| Company Certifications | ISO 9002:2000 |

2. Manufacturer Certificates

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period |

3. Manufacturer Capability

| a) Trade Capacity | |

| Nearest Port | Shanghai |

| Export Percentage | 41% - 50% |

| No.of Employees in Trade Department | 100 People |

| Language Spoken: | Chinese |

| b) Factory Information | |

| Factory Size: | Above 100,000 square meters |

| No. of Production Lines | Above 5 |

| Contract Manufacturing | OEM Service Offered; Design Service Offered |

| Product Price Range | Average |

Send your message to us

FRP Roofing Panel S15 - High Quality FRP Panels

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 100Pcs m.t.

- Supply Capability:

- 1000Pcs m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords