Frp Roof Panels Southerland - Fiber Reinforce Plastic Sheet Panel with 1.5 mm Thickness

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 20000 m²

- Supply Capability:

- 100000000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Fiber Reinforce Plastic Sheet Panel with 1.5 mm Thinkness

Description

In general, our company specializes in FRP grating, FRP decking, FRP platform and other products of FRP. We have a varity of FRP products sold over the country because we have our own teams of design, manufacturing and sales with hundreds of staffs.

At the same time, we are devoted to creating a production and marketing for FRP products, which has certain influence in China by proceeding with professional teams, rigorous quality management system and advanced production facility. Today, we’re planning to win more market shares in the world and let more customers know us.

Product Traits

1)High light transparency

2)Light weight and high strength

3)Corrosion and impact resistance

4)Anti-UV, anti-static, insulation

5)Accurate cross-section size

6)The length of the random cutting and more

7)Widely used in industrial plants, large-scale treasury markets, greenhouse, aquaculture and tourism

8)Used as roof, wall panel and more

9)Supports good lighting effect

Product Advantage

Corrosion Resistant

Light Weight,High Strength and Impact & Fatigue Resistant.

Non-Conductive & Non-Magnetic

Maintenance Free

Fire Retardant

Dimensional Stability

Easy Assembly

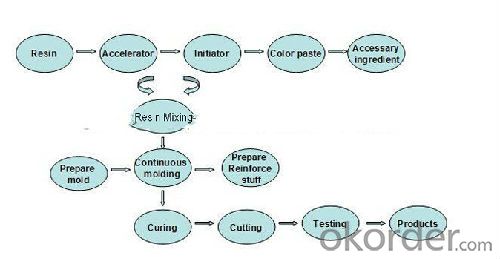

Production Process

Specification

Unit Weight: 1800g/m² 2400g/m² 3050g/m²

Nominal Thickness:0.8mm,1.0mm, 1.2mm 1.5mm 2.0mm, 2.5mm

Heat Resistance Limit: -60 to +130

Light Transmittance: 75%±2% ( light green) 53%±2% (cream white)

Anti- ultraviolet Rate: 99.9%

Tensile Strength: 100Mpa

Flexural Strength: 180Mpa

Cracking Elongation Rate: 1.9%

Pasture Hardness: ≥50

Thermal Expansion Coefficient: 2.2×10¯125px/cm/

Thermal Conductivity: 0.18w/m° k

Photos

The Raw Materials of WANT Pultruded Profiles Fiberglass plank

For services in different extreme environments, WANT provides a number of choices for rovings, mats, resin and others to meet customer's demands. Both orthophthalic and isophthalic polyester resin are most commonly used, whilst vinyl ester resins are also available upon request. We can provide profiles of various shapes and colors with alternative options for various mats, veils, as well as other additives for different application.

FAQ

1.Which country do you mainly export to?

A: Our products are very popular in Mid East, India, South East Asia, Latin America, Africa.

2.Q: What’s the advantage of you compared with other suppliers experienced in foreign trade?

A: We have been specialized in FRP products for over decades years and approved by many domestic companies. Except for our quality and price, we’re also able to give you the best service.

3.Q:Can you provide some samples?

A: Yes, of course. We will send you samples for your confirmation before you place firm orders.

- Q: Are FRP roofing panels resistant to fading or yellowing?

- Yes, FRP (Fiberglass Reinforced Plastic) roofing panels are generally resistant to fading and yellowing. FRP panels are made with a special gel coat that provides excellent UV resistance, protecting them from the harmful effects of sunlight exposure. This gel coat acts as a barrier, preventing the panels from fading or yellowing over time. However, it is important to note that the longevity of the color and appearance of FRP roofing panels can still be influenced by factors such as the quality of the gel coat, maintenance practices, and the intensity and duration of sun exposure. Regular cleaning and maintenance can help to preserve the color and appearance of FRP roofing panels for an extended period.

- Q: Can FRP roofing panels be installed on curved roofs?

- Indeed, it is possible to install FRP roofing panels on curved roofs. The flexibility of FRP panels enables them to effortlessly conform to the curves and contours of such roofs. They can be shaped or curved without the risk of cracking or breaking, resulting in a flawless and resilient installation on curved roofs. Nevertheless, it is essential to consider that the level of curvature and the particular design of the curved roof may impact the installation procedure. Therefore, it is advisable to seek guidance from a skilled roofing contractor to guarantee a proper installation.

- Q: Can FRP roofing panels be used for canopies over entrances?

- Yes, FRP (Fiberglass Reinforced Plastic) roofing panels can be used for canopies over entrances. FRP panels are lightweight, durable, and have excellent weather resistance, making them suitable for outdoor applications such as canopies. They can provide protection from the elements and create an inviting and visually appealing entrance. Additionally, FRP panels are available in various colors, textures, and designs, allowing for customization to match the aesthetic requirements of the building or entrance.

- Q: Are FRP roofing panels suitable for restaurants or food establishments?

- Yes, FRP (Fiberglass Reinforced Plastic) roofing panels are suitable for restaurants or food establishments. FRP roofing panels are a popular choice for these types of establishments due to their numerous beneficial qualities. Firstly, FRP panels are highly durable and long-lasting. They are resistant to corrosion, rot, and mold, making them ideal for environments that may have exposure to moisture or humidity, such as commercial kitchens or food processing areas. This ensures that the panels will maintain their structural integrity and appearance over time, minimizing the need for frequent repairs or replacements. Additionally, FRP roofing panels are lightweight yet strong, making them easy to install and handle. This can be especially advantageous for restaurants or food establishments that require quick installation or renovations. The lightweight nature of the panels also reduces the strain on the building's structure, which can be a significant factor in older or existing establishments. Furthermore, FRP panels offer excellent insulation properties. They can help maintain a comfortable indoor temperature by preventing heat loss or gain, which is particularly important in food establishments where temperature control is crucial for food safety and operational efficiency. Moreover, FRP panels are available in a wide range of colors, finishes, and designs, allowing for customization that suits the aesthetic requirements of restaurants or food establishments. This versatility allows for the creation of visually appealing spaces that align with the brand identity or theme of the establishment. Lastly, FRP panels are relatively low maintenance and easy to clean. Their smooth, non-porous surface prevents the buildup of dirt, grease, or food particles, reducing the risk of bacterial growth or contamination. Regular cleaning with mild detergents or sanitizers is usually sufficient to maintain their cleanliness and hygiene standards. Overall, FRP roofing panels are a suitable choice for restaurants or food establishments due to their durability, resistance to moisture, ease of installation, insulation properties, customization options, and low maintenance requirements.

- Q: Are FRP roofing panels resistant to water leaks?

- Yes, FRP roofing panels are highly resistant to water leaks. The fiberglass-reinforced plastic material used in FRP panels is inherently waterproof and does not absorb water. Additionally, the panels are designed with overlapping edges and sealants to provide a secure and watertight barrier, preventing any leaks or water seepage.

- Q: Can FRP roofing panels be used in prisons or correctional facilities?

- Yes, FRP (Fiberglass Reinforced Plastic) roofing panels can be used in prisons or correctional facilities. FRP panels are highly durable, resistant to damage, and have low maintenance requirements, making them suitable for such facilities. They are also lightweight, non-corrosive, and resistant to water, chemicals, and fire, which are important considerations in secure environments like prisons. Additionally, FRP panels can be customized to meet specific security and safety requirements, making them a viable option for roofing in correctional facilities.

- Q: Are FRP roofing panels suitable for shopping malls or retail complexes?

- Yes, FRP (Fiberglass Reinforced Plastic) roofing panels can be suitable for shopping malls or retail complexes. FRP roofing panels have several advantages that make them a viable option for commercial buildings such as shopping malls or retail complexes. Firstly, FRP panels are lightweight yet strong, making them easy to install and capable of withstanding heavy loads. This is important for large commercial buildings that may require long-span roofing systems. Additionally, FRP panels are highly durable and resistant to corrosion, chemicals, and UV rays. This means that they can withstand harsh weather conditions and maintain their appearance for an extended period of time. Shopping malls and retail complexes often have rooftop HVAC units and other equipment, and FRP panels can provide effective protection against leaks and damage from such installations. Furthermore, FRP panels are available in a variety of designs, colors, and textures, allowing for customization to match the architectural style of the building. This can enhance the overall aesthetics of the shopping mall or retail complex, creating an inviting and visually appealing environment for customers. Moreover, FRP roofing panels offer excellent light transmission properties, allowing natural light to enter the building and reducing the need for artificial lighting during the day. This can result in energy savings and contribute to a more sustainable and eco-friendly building design. Overall, the durability, versatility, and aesthetic appeal of FRP roofing panels make them a suitable choice for shopping malls or retail complexes. They provide long-lasting protection, enhance the architectural design, and contribute to energy efficiency, making them a practical and cost-effective roofing solution for commercial buildings.

- Q: Are FRP roofing panels suitable for bus shelters or transit stations?

- Yes, FRP (Fiberglass Reinforced Plastic) roofing panels are suitable for bus shelters or transit stations. FRP roofing panels are known for their durability, strength, and resistance to weather conditions, making them an ideal choice for outdoor structures like bus shelters or transit stations. Firstly, FRP panels have excellent resistance to UV radiation, which means they can withstand prolonged exposure to sunlight without fading or degrading. This is particularly important for bus shelters or transit stations that are typically located outdoors and are subject to constant exposure to sunlight. Secondly, FRP panels are highly resistant to moisture and water damage. They do not absorb water, preventing issues like rotting or warping that can occur with other roofing materials. This is particularly beneficial for bus shelters or transit stations, as they are often exposed to rain, snow, and other forms of precipitation. Additionally, FRP panels are lightweight yet strong, making them easy to install while still providing sufficient structural support. This is advantageous for bus shelters or transit stations, as it reduces installation time and costs. Moreover, FRP panels are low maintenance and resistant to corrosion, making them a cost-effective choice for long-term use. They do not require frequent painting or sealing, and their durability ensures they can withstand the wear and tear associated with high-foot traffic areas. Overall, FRP roofing panels are an excellent choice for bus shelters or transit stations due to their durability, weather resistance, low maintenance requirements, and cost-effectiveness.

- Q: Can FRP roofing panels be used in agricultural storage buildings?

- Yes, FRP (Fiberglass Reinforced Plastic) roofing panels can be used in agricultural storage buildings. FRP roofing panels offer several advantages that make them suitable for such applications. Firstly, FRP panels are lightweight, which makes them easy to handle and install. This is particularly beneficial in agricultural storage buildings where large roof areas need to be covered. Additionally, FRP panels are extremely durable and resistant to corrosion, chemicals, and UV radiation. This makes them ideal for agricultural environments where exposure to harsh weather conditions, chemicals, and farming activities is common. FRP panels also have excellent thermal insulation properties, which can help in maintaining a suitable temperature inside the storage building. Moreover, FRP panels are available in various colors and finishes, allowing for customization to match the aesthetic requirements of the building. Overall, FRP roofing panels are a cost-effective and reliable option for agricultural storage buildings due to their lightweight, durability, resistance to corrosion, and thermal insulation properties.

- Q: Are FRP roofing panels suitable for buildings in coastal areas?

- Yes, FRP roofing panels are suitable for buildings in coastal areas. FRP panels are known for their durability and resistance to corrosion, making them an excellent choice for coastal environments where high humidity, saltwater, and strong winds are common. Additionally, FRP panels offer superior UV protection, ensuring they can withstand the harsh sun exposure often experienced in coastal regions.

Send your message to us

Frp Roof Panels Southerland - Fiber Reinforce Plastic Sheet Panel with 1.5 mm Thickness

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 20000 m²

- Supply Capability:

- 100000000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords