Wholesale FRP Translucent Fibreglass Corrugated Roofing Sheets

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 300 m

- Supply Capability:

- 80000 m/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

PRODUCT DESCRIPTION

Fibreglass / Fiberglass Reinforced Plastic (FRP) or Glass Fiber Reinforced Plastic (GRP) is composed of thermosetting plastics and reinforced fiberglass, Greater than that of steel products and aluminum products in specific tenacity. Products in the ultra-low temperature or high temperature will not happen brittle fracture, deformation and to prevent heat transfer. Corrosion products in the environment anti-aging, yellowing resistance, corrosion resistance, friction resistance, easy to clean. Can be instead of aluminum, stainless steel plates, tiles and so on.

FEATURES

Corrosion resistance,last 10-15 years life span

Color stable.

Sound absorption and heat insulation.

Good water resistance.

Fireproof resistance.

Easy to install.

Good impact and low temperature resistance.

Light weight.

Stable volume.

SPECIFICATIONS

| Name: | Fibreglass Reinforced Polyester(FRP ) Sheet |

| Material: | Protective film, Unsaturated resin polyester, Fiberglass |

| Weight: | 1800g/2400g/2750g/3050g Square meter |

| Thickness: | 0.8~3.0mm |

| Length: | Customized |

| Temp: | used in -40°c to 140 °c |

| OEM: | Welcomed |

| Color: | Clear/Blue |

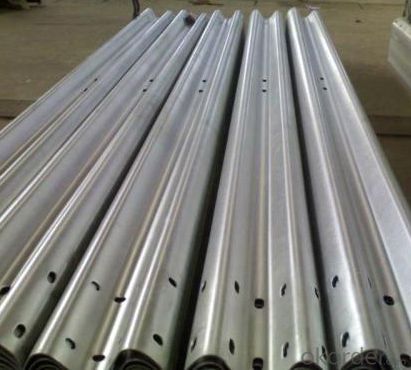

PICTURES

- Q: Can FRP roofing panels be used for modular office buildings or construction sites?

- Yes, FRP (Fiberglass Reinforced Plastic) roofing panels can be used for modular office buildings or construction sites. FRP panels are highly durable, lightweight, and resistant to corrosion, making them suitable for various applications. They offer excellent performance in terms of weather resistance, insulation, and fire resistance, making them a reliable choice for roofing in modular office buildings or construction sites. Additionally, FRP panels are easy to install and maintain, making them a practical option for such projects.

- Q: Can FRP roofing panels be used for green roofs?

- FRP roofing panels are indeed suitable for green roofs, as they are specifically designed to accommodate the growth of plants and vegetation. With their lightweight, durable, and highly resistant properties against water and weathering, FRP panels make an ideal foundation for green roof applications. Moreover, these panels can be customized to include specialized features such as drainage systems or built-in insulation, further augmenting their suitability for green roof installations. In summary, FRP roofing panels provide a dependable and enduring solution for constructing green roofs.

- Q: Are FRP roofing panels suitable for recreational vehicles?

- Yes, FRP (Fiberglass Reinforced Panels) roofing panels are suitable for recreational vehicles. These panels are made from a combination of fiberglass and resin, which makes them lightweight yet durable. They are resistant to corrosion, UV rays, and extreme weather conditions, which are all important factors for RVs that are constantly exposed to the elements. FRP roofing panels also provide excellent insulation properties, helping to keep the interior of the RV cool in hot weather and warm in cold weather. This can greatly enhance the overall comfort level inside the vehicle, especially during long trips. Additionally, FRP panels are easy to install and maintain. They can be easily cut to fit the desired size and shape, allowing for customization and flexibility during the installation process. They are also resistant to mold, mildew, and rotting, ensuring a longer lifespan for the RV roof. Overall, FRP roofing panels are a great choice for recreational vehicles due to their lightweight nature, durability, weather resistance, insulation properties, and ease of installation and maintenance.

- Q: Can FRP roofing panels be used for cold storage facilities?

- FRP roofing panels are capable of being utilized in cold storage facilities, providing exceptional insulation, durability, and resistance to corrosion. These qualities render them appropriate for environments necessitating temperature regulation, like cold storage facilities. The effective thermal insulation offered by FRP roofing panels effectively hinders the transfer of heat between the interior and exterior of the facility. Consequently, a consistent and regulated temperature is maintained within the cold storage facility, guaranteeing that perishable items are preserved at the desired temperature. Furthermore, FRP panels exhibit moisture resistance and the ability to endure low temperatures, making them an optimal selection for cold storage purposes.

- Q: Can FRP roofing panels be used for walkways or catwalks?

- No, FRP roofing panels are not typically designed or recommended for use as walkways or catwalks. They are primarily used as roofing materials and may not provide the necessary strength, durability, or slip resistance required for walkway or catwalk applications. It is advisable to use materials specifically designed for these purposes to ensure safety and functionality.

- Q: Can FRP roofing panels be installed over an existing roof?

- Installing FRP roofing panels over an existing roof is indeed possible. However, several factors warrant consideration before proceeding with this installation approach. Initially, it is crucial to ascertain the soundness of the current roof's structure and its ability to withstand the weight of the FRP panels. Additionally, any pre-existing leaks or damages should be addressed and repaired before installing the new panels. Ensuring appropriate insulation and ventilation is also vital to prevent condensation and moisture buildup between the existing roof and the FRP panels. Lastly, it is advisable to consult a professional roofing contractor with expertise in FRP installations to guarantee optimal outcomes and adherence to local building codes and regulations.

- Q: Are FRP roofing panels resistant to graffiti or spray paint?

- Graffiti or spray paint is generally unable to adhere properly to FRP (Fiber Reinforced Plastic) roofing panels due to their smooth and non-porous surface. This makes it easier to remove any unwanted markings. Moreover, manufacturers often apply a protective gel coating to FRP panels, enhancing their resistance to various substances, including graffiti. However, it is important to note that while FRP panels offer resistance to graffiti, they are not completely immune to it. In rare cases, if graffiti is left unattended for a long time, it may become more difficult to remove entirely. Therefore, it is recommended to promptly clean any graffiti or spray paint from FRP roofing panels to ensure their durability and aesthetic appeal in the long run.

- Q: Are FRP roofing panels resistant to warping due to heat?

- FRP roofing panels are renowned for their ability to resist warping caused by heat. These panels are crafted using a blend of fiberglass and plastic resin, resulting in superior structural strength and stability. This unique composition enables FRP panels to endure high temperatures without warping or distorting. They possess a high coefficient of expansion, allowing them to expand and contract without significant effects on their overall shape and integrity. Consequently, FRP roofing panels are especially suitable for regions with extreme heat or fluctuating temperatures. Furthermore, these panels exhibit exceptional thermal insulation properties, further minimizing the impact of heat on them. Overall, FRP roofing panels exhibit remarkable resistance to heat-induced warping, cementing their status as a durable and dependable choice for roofing applications.

- Q: Are FRP roofing panels resistant to extreme temperatures?

- Yes, FRP (Fiberglass Reinforced Plastic) roofing panels are known for their excellent resistance to extreme temperatures. FRP panels are designed to withstand a wide range of temperature variations, making them suitable for use in both hot and cold climates. They have a low coefficient of thermal expansion, meaning they expand and contract minimally with temperature changes, which helps prevent warping, cracking, or delamination. Additionally, FRP roofing panels are often integrated with UV stabilizers and heat-resistant additives during manufacturing, further enhancing their ability to withstand extreme temperatures and prolonged exposure to sunlight. This makes FRP roofing panels a reliable and durable choice for various applications, including industrial, commercial, and residential buildings in areas with extreme temperature fluctuations.

- Q: Are FRP roofing panels resistant to graffiti?

- Yes, FRP (Fiberglass Reinforced Plastic) roofing panels are resistant to graffiti. The smooth surface of FRP panels makes it difficult for graffiti to adhere, and even if it does, it can be easily removed without causing any permanent damage to the panel.

Send your message to us

Wholesale FRP Translucent Fibreglass Corrugated Roofing Sheets

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 300 m

- Supply Capability:

- 80000 m/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords