High Quality FRP Roofing Panel - Fire Resistance FRP Roofing Sheet

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 22 m

- Supply Capability:

- 50000 m/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

PRODUCT DESCRIPTION

FRP GRP Fiberglass Glassfiber Corrugated Roofing is a patent of our company, not like other FRP products, it is produced without yarn, instead, we use mat only. Therefore, the corrugated sheet is more strong in both horizontal and vertical direction.

Cold rolled sheet has superb sheet shape and surface quality with good flatness and surface finish. The surface of the cold sheet is clean and bright and easy for coating. The varieties of cold rolled sheet are widely used in galvanized substrates, home appliances, tubing, automobiles, building, enamels and other industries.

FEATURES

1) The fiberglass content of new generation greenhouse panel has been improved by 18.3%.

2) Weather resistant and Self-clean ability.

3) Excellent yellowness resistance.

4) Strong impact resistant and low bending rate.

5)Withstand extreme temperature from -38 degree to +110 degree for a long time

6) Aging resistant: specified F4 film added on surface and gel coat makes it endurable for long.

7) More strengthened, safer, cleaner and more economical greenhouse panel.

8) Mainly serve the big factory, warehouse, super markets and other steel-structured project.

SPECIFICATION

Name: | FRP Roofing |

Material: | Fiberglass |

Width: | 880mm/1050mm |

Effective width: | 800mm/960mm |

Wave length: | 160mm |

Wave height: | 30mm |

Pitch: | 220mm |

Thickness: | 3/2.5mm |

Length: | Customized but must be a multiple of wave pitch |

Color: | Purplish Red, Brick Red, Grey, Green, Blue or customized |

Application: | House, villa, pavilions, industrial plants, large warehouses, supermarkets, stadiums etc |

MOQ: | 1000 Square meter |

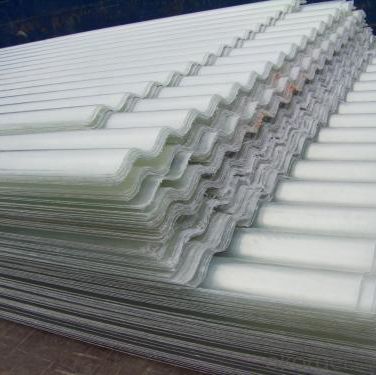

PICTURES

- Q: Can FRP roofing panels be used for both residential and commercial green walls?

- Yes, FRP roofing panels can be used for both residential and commercial green walls. The durable and lightweight nature of FRP panels makes them suitable for vertical gardens and green walls in various settings. Their resistance to moisture, UV rays, and chemicals ensures long-lasting performance in both residential and commercial applications.

- Q: Can FRP roofing panels be used for universities?

- Yes, FRP roofing panels can be used for universities. FRP (Fiberglass Reinforced Plastic) roofing panels are lightweight, durable, and resistant to corrosion, making them suitable for various applications, including universities. They provide excellent weather protection, low maintenance requirements, and can be customized to fit different architectural styles. Additionally, FRP panels can offer energy efficiency benefits by reducing heat transfer, enhancing insulation, and allowing the integration of natural lighting.

- Q: Can FRP roofing panels be used in renovation projects?

- Yes, FRP (Fiberglass Reinforced Plastic) roofing panels can definitely be used in renovation projects. FRP panels are known for their durability, strength, and resistance to various weather conditions, which makes them an excellent choice for roofing applications. They can be installed on various types of structures, including residential, commercial, and industrial buildings. In renovation projects, FRP roofing panels can be used to replace old or damaged roofs, providing a cost-effective and long-lasting solution. They are lightweight and easy to install, which can help expedite the renovation process. Moreover, FRP panels come in a variety of colors, finishes, and profiles, allowing for customization to match the design and aesthetic requirements of the project. Another advantage of FRP roofing panels is their low maintenance requirements. They are resistant to corrosion, rot, and UV damage, making them suitable for long-term use. Additionally, FRP panels offer good insulation properties, helping to regulate temperature and reduce energy costs. Overall, FRP roofing panels can be a great choice for renovation projects due to their durability, ease of installation, customization options, low maintenance needs, and energy efficiency. They offer a reliable and attractive roofing solution, ensuring the longevity and improved functionality of renovated structures.

- Q: Can FRP roofing panels be used in earthquake-prone areas?

- Yes, FRP (Fiberglass Reinforced Plastic) roofing panels can be used in earthquake-prone areas. FRP panels are known for their strength, durability, and resistance to various environmental factors, including earthquakes. They are designed to withstand high winds, heavy rain, and seismic activity. The use of FRP roofing panels in earthquake-prone areas offers several advantages. First, FRP panels are lightweight, which reduces the overall structural load on the building. This can help minimize the impact of seismic forces on the building's foundation and structure. Second, FRP panels have high tensile strength, meaning they can withstand the stress and movement caused by earthquakes. Their flexibility allows them to absorb and distribute the seismic energy, reducing the risk of damage or collapse. Additionally, FRP panels have excellent impact resistance, which is crucial in earthquake-prone areas where debris and falling objects can cause significant damage. Furthermore, FRP panels are non-corrosive and have a long lifespan, making them an ideal choice for areas prone to earthquakes. They do not rust or deteriorate over time, ensuring their durability and reliability during seismic events. It is important to note that the installation and design of FRP roofing panels in earthquake-prone areas should comply with local building codes and regulations. Adequate structural support and proper anchoring methods are essential to maximize the performance and safety of FRP roofing panels in seismic events. Overall, FRP roofing panels can be effectively used in earthquake-prone areas, providing a resilient and reliable roofing solution that can withstand the challenges posed by seismic activity.

- Q: Can FRP roofing panels be used for roof repairs?

- Yes, FRP (Fiberglass Reinforced Plastic) roofing panels can be used for roof repairs. These panels are lightweight, durable, and resistant to weather elements, making them suitable for fixing damaged roofs. Additionally, FRP panels are easy to install and can provide a cost-effective solution for roof repairs.

- Q: Can FRP roofing panels be installed in curved structures?

- Curved structures can indeed accommodate FRP roofing panels. The flexibility and adaptability of FRP (Fiberglass Reinforced Plastic) roofing panels make them a perfect fit for installation on curved surfaces. These panels can effortlessly be molded and contoured to match the structure's curvature, ensuring a flawless and secure installation. Furthermore, FRP roofing panels are lightweight but exceptionally durable, making them a superior choice for curved structures where traditional roofing materials may not be suitable or as effective. In conclusion, FRP roofing panels offer both aesthetic allure and dependable performance, making them an excellent option for curved structures.

- Q: Are FRP roofing panels prone to cracking from seismic activity?

- FRP (Fiber Reinforced Polymer) roofing panels are known for their durability and strength, making them capable of withstanding various environmental factors. However, when it comes to seismic activity, there is a possibility of these panels cracking. The severity of cracking largely depends on the intensity and duration of the seismic event. While FRP roofing panels have some flexibility, they can still be susceptible to cracking if subjected to significant vibrations and movements caused by an earthquake. Cracking can occur due to the stress concentration at specific points or weak areas of the panel. The likelihood of cracking can also be influenced by the quality of the FRP material, the installation process, and the design of the roofing system. However, it is worth noting that FRP roofing panels are designed and manufactured to be more resistant to cracking compared to other roofing materials. The use of fiber reinforcement significantly enhances their structural integrity, making them less prone to damage from seismic activity compared to traditional roofing materials like concrete or clay tiles. To mitigate the risk of cracking, it is crucial to ensure that the FRP roofing panels are properly installed and securely fastened to the supporting structure. Additionally, regular inspections and maintenance should be carried out to identify any signs of damage or weakening, allowing for timely repairs or reinforcements to be made. Overall, while FRP roofing panels may have some vulnerability to cracking during seismic events, their durability and strength make them a reliable choice for areas prone to earthquakes. By employing proper installation techniques and regular maintenance, the risk of cracking can be minimized, ensuring the longevity and performance of the FRP roofing system.

- Q: Can FRP roofing panels be used for storage buildings?

- Yes, FRP roofing panels can be used for storage buildings. FRP panels are durable, lightweight, and resistant to corrosion and UV rays, making them suitable for various applications including storage buildings. They provide excellent insulation and protection against weather elements, ensuring the safety and longevity of the stored items.

- Q: Can FRP roofing panels be used for shopping centers?

- Yes, FRP (Fiberglass Reinforced Plastic) roofing panels can be used for shopping centers. FRP panels are known for their durability, lightweight nature, and resistance to corrosion, making them suitable for a variety of applications, including commercial buildings like shopping centers. Additionally, FRP panels are available in various colors and designs, allowing for customization to match the aesthetic requirements of the shopping center. Furthermore, FRP panels provide excellent insulation properties, helping to reduce energy costs. Overall, FRP roofing panels can be a cost-effective and reliable choice for shopping centers, offering both functionality and aesthetic appeal.

- Q: Are FRP roofing panels compatible with different types of flashing systems?

- Yes, FRP roofing panels are compatible with a variety of flashing systems. These panels can be easily integrated with different types of flashing systems, such as metal or PVC, to ensure proper waterproofing and protection against leaks. Proper installation and sealing techniques are crucial to ensure a secure and durable connection between the FRP panels and the flashing system.

Send your message to us

High Quality FRP Roofing Panel - Fire Resistance FRP Roofing Sheet

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 22 m

- Supply Capability:

- 50000 m/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords