FRP Roofing Panel B - High Quality FRP Roofing Panel

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 100Pcs m.t.

- Supply Capability:

- 1000Pcs m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

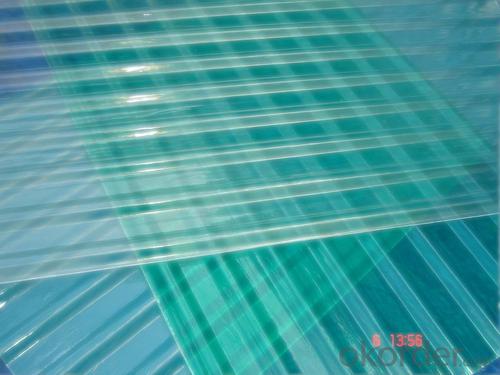

Specification of FRP Roofing Panel

Thickness:1.2mm

Color:sky blue, dark blue, clear, light green, dark green, opal, etc.

Ordinary Wave: 760-380

Length:No limit but with the consideration of transportation

Features of FRP Roofing Panel:

1) The fiberglass content of new generation greenhouse panel has been improved by 18.3%

2) Weather resistant and Self-clean ability

3) Excellent yellowness resistance

4) Strong impact resistant and low bending rate

5)Withstand extreme temperature from -38 degree to +110 degree for a long time

6) Aging resistant: specified F4 film added on surface and gel coat makes it endurable

for long.

7) More strengthened, safer, cleaner and more economical greenhouse panel.

8) Mainly serve the big factory, warehouse, super markets and other steel-structured project.

Packaging & Delivery

Packaging Detail: standard packing for export

Delivery Detail:3~7 days

- Q: Are FRP roofing panels resistant to acid or corrosive environments?

- FRP (Fiberglass Reinforced Plastic) roofing panels are known for their exceptional resistance to corrosion and chemicals, including acids. The composition of FRP includes a fiberglass matrix that is reinforced with plastic, providing it with a high level of durability and resistance to corrosive environments. This makes FRP roofing panels an excellent choice for applications where exposure to acids or other corrosive substances is a concern. Additionally, FRP panels are also resistant to UV rays, moisture, and temperature variations, further enhancing their longevity and ability to withstand harsh conditions. Overall, FRP roofing panels are a reliable and long-lasting solution for structures that require protection against acid or corrosive environments.

- Q: Can FRP roofing panels be used for hospitals?

- Yes, FRP roofing panels can be used for hospitals. FRP (Fiberglass Reinforced Plastic) roofing panels are a durable and lightweight option that can provide excellent insulation and weather resistance. They are commonly used in various industries, including healthcare facilities such as hospitals, due to their ability to withstand harsh conditions, offer energy efficiency, and require low maintenance. Additionally, FRP panels can be customized to meet specific design requirements, making them suitable for hospitals with unique architectural needs.

- Q: Can FRP roofing panels be installed on curved or domed roofs?

- Yes, FRP (Fiberglass Reinforced Plastic) roofing panels can be installed on curved or domed roofs. These panels are flexible and can be bent or curved to fit the desired roof shape. This makes them a suitable choice for unconventional roof designs or structures with curved or domed roofs.

- Q: Are FRP roofing panels suitable for coastal areas with high salt exposure?

- FRP roofing panels are suitable for coastal areas with high salt exposure. They are renowned for their durability and resistance to corrosion, making them an excellent choice for regions where the air has a high salt content. The reinforcement of fiberglass in FRP panels provides additional strength and stability, making them highly resistant to the damaging effects of saltwater and salt-laden air. Consequently, FRP roofing panels are an ideal solution for coastal areas where traditional roofing materials may deteriorate quickly due to salt exposure. Moreover, FRP roofing panels also exhibit resistance to UV radiation, which is another common factor in coastal environments. Thus, FRP roofing panels offer a reliable and long-lasting solution for coastal areas with high salt exposure.

- Q: How long do FRP roofing panels last?

- The durability and longevity of FRP roofing panels are well-known. With proper installation and maintenance, these panels can typically last anywhere from 20 to 30 years. However, the lifespan of FRP roofing panels can be influenced by factors such as panel quality, climate conditions, and maintenance level. If high-quality FRP roofing panels are installed correctly and maintained regularly, they can last even longer, possibly exceeding 40 years. Regular maintenance involves checking for damage, cleaning the panels to remove dirt and debris, and ensuring proper sealing to prevent water leakage. Furthermore, exposure to extreme weather conditions like hail, heavy snow, or strong winds can impact the lifespan of FRP roofing panels. Regular inspections and timely repairs or replacements can help extend their lifespan. It is important to understand that although FRP roofing panels are durable and long-lasting, their lifespan can be affected by various factors. Therefore, it is advisable to consult a professional roofing contractor who can evaluate your specific situation and provide accurate information about the expected lifespan of FRP roofing panels in your particular location and circumstances.

- Q: Are FRP roofing panels suitable for green roof applications?

- Yes, FRP roofing panels are suitable for green roof applications. FRP panels provide excellent durability, weather resistance, and insulation properties, making them an ideal choice for green roofs. They can also be customized to accommodate drainage systems and support the weight of the vegetation. Additionally, FRP panels offer easy installation and low maintenance, making them a practical option for green roof projects.

- Q: Can FRP roofing panels be used for exterior cladding?

- Yes, FRP roofing panels can be used for exterior cladding. FRP (Fiberglass Reinforced Plastic) roofing panels are known for their durability, strength, and weather resistance, making them suitable for various applications including exterior cladding. They provide an attractive appearance while protecting the building from external elements such as rain, wind, and UV rays. Additionally, FRP panels are lightweight and easy to install, making them a popular choice for cladding projects.

- Q: Can FRP roofing panels be installed on metal structures?

- Yes, FRP (Fiberglass Reinforced Plastic) roofing panels can be installed on metal structures. FRP roofing panels are lightweight and durable, making them suitable for various applications including metal structures. They can be easily installed on metal roofs using various methods such as screwing, nailing, or using adhesive. FRP panels provide excellent resistance to corrosion, UV rays, and extreme weather conditions, which makes them a popular choice for industrial and commercial buildings. Additionally, their translucency allows natural light to enter the structure, reducing the need for artificial lighting. Overall, FRP roofing panels are a versatile and practical option for metal structures.

- Q: Are FRP roofing panels resistant to warping due to heat?

- Yes, FRP (Fiberglass Reinforced Plastic) roofing panels are known for their excellent resistance to warping due to heat. FRP panels are made from a combination of fiberglass and plastic resin, which provides them with exceptional structural strength and stability. This composition allows FRP panels to withstand high temperatures without warping or distorting. They have a high coefficient of expansion, meaning they can expand and contract with minimal impact on their overall shape and integrity. This makes FRP roofing panels an ideal choice for areas with extreme heat or fluctuating temperatures. Additionally, FRP panels have excellent thermal insulation properties, which further helps in reducing the impact of heat on the panels. Overall, FRP roofing panels are highly resistant to warping due to heat, making them a durable and reliable choice for roofing applications.

- Q: Are FRP roofing panels resistant to chemical spills or leaks?

- Yes, FRP (fiberglass reinforced plastic) roofing panels are resistant to chemical spills or leaks. FRP panels are made of a combination of fiberglass and plastic materials, which provide excellent resistance to a wide range of chemicals. The panels are designed to be non-reactive and non-corrosive, making them highly resistant to the effects of chemical exposure. This resistance is particularly important in industrial or commercial settings where there is a higher likelihood of chemical spills or leaks occurring. FRP roofing panels have been tested and proven to withstand various chemicals, including acids, solvents, and oils, without deteriorating or sustaining damage. Therefore, they are a reliable choice for environments where chemical resistance is a primary concern.

1. Manufacturer Overview

| Location | Shanghai, China |

| Year Established | 1999 |

| Annual Output Value | Above US$ 300,000 |

| Main Markets | Mid East; Eastern Europe; North America |

| Company Certifications | ISO 9002:2000 |

2. Manufacturer Certificates

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period |

3. Manufacturer Capability

| a) Trade Capacity | |

| Nearest Port | Shanghai |

| Export Percentage | 41% - 50% |

| No.of Employees in Trade Department | 100 People |

| Language Spoken: | Chinese |

| b) Factory Information | |

| Factory Size: | Above 100,000 square meters |

| No. of Production Lines | Above 5 |

| Contract Manufacturing | OEM Service Offered; Design Service Offered |

| Product Price Range | Average |

Send your message to us

FRP Roofing Panel B - High Quality FRP Roofing Panel

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 100Pcs m.t.

- Supply Capability:

- 1000Pcs m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords