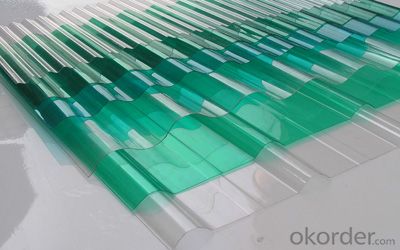

High strength Transparent corrugated FRP/GRP panel

- Loading Port:

- China main port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 100 kg

- Supply Capability:

- 100000 kg/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1.Brief Introduction

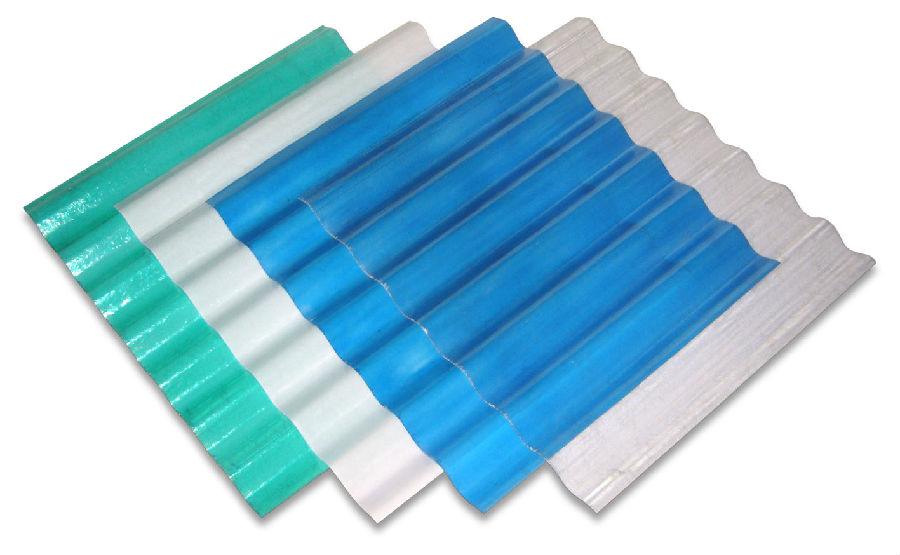

Fibreglass sheet,FRP panels,fibreglass panel,corrugated sheet can be used in many kinds of fileds such as building etc.It includes transparent ,lightblue ,red and other colors.

2.Characteristics

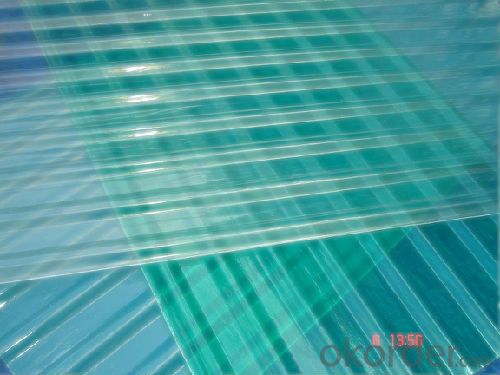

1)High light transparency

2)Light weight and high strength

3)Corrosion and impact resistance

4)Anti-UV, anti-static, insulation

5)Accurate cross-section size

6)The length of the random cutting and more

7)Widely used in industrial plants, large-scale treasury markets, greenhouse, aquaculture and tourism

8)Used as roof, wall panel and more

9)Supports good lighting effect

3.Technical Data Sheet

Unit Weight: 1800g/m² 2400g/m² 3050g/m²

Nominal Thickness:0.8mm,1.0mm, 1.2mm 1.5mm 2.0mm, 2.5mm

Heat Resistance Limit: -60 to +130

Light Transmittance: 75%±2% ( light green) 53%±2% (cream white)

Anti- ultraviolet Rate: 99.9%

Tensile Strength: 100Mpa

Flexural Strength: 180Mpa

Cracking Elongation Rate: 1.9%

Pasture Hardness: ≥50

Thermal Expansion Coefficient: 2.2×10¯125px/cm/

Thermal Conductivity: 0.18w/m° k

Warranty:15 years

Item | Data | Reference | Item | Data | Reference |

Tensile modulus(Gpa) | 6.92 | GB | catalyst cold temperature | -52 | GB |

tensile strength(Gpa) | 103 | GB | heat distortion temperature | 172 | GB |

flexural modulus(Gpa) | 6.00 | GB | glass fiber content | above30% | GB |

flexural strength(Gpa) | 171 | GB | water absorption% | 0.18 | GB |

shear strength(Gpa) | 89.9 | GB | specific gravity | 1.48g/cm² | GB |

Barcol hardness | 47 | GB | Coefficient of thermal expansion | 1.5-2.2*10-5 | GB |

4.FAQ

a.Delivery Time: The products will be ready in 10-15 days after getting the advance payment or LC.

b.Payment Term:30% T/T in advance,70% againest B/L copy or LC.

- Q: Are FRP roofing panels suitable for high wind areas?

- Yes, FRP (Fiberglass Reinforced Plastic) roofing panels are suitable for high wind areas. FRP roofing panels are known for their exceptional strength and durability, making them highly resistant to strong winds. The fiberglass reinforcement in the panels provides added structural integrity, allowing them to withstand the forces exerted by high winds without becoming damaged or dislodged. Additionally, FRP roofing panels are designed to be securely fastened to the roof structure, further enhancing their ability to resist wind uplift and maintain their integrity in high wind areas.

- Q: Can FRP roofing panels be used for sheds?

- Yes, FRP (Fiberglass Reinforced Plastic) roofing panels can be used for sheds. FRP panels are lightweight, durable, and offer excellent weather resistance, making them a suitable choice for shed roofing. They provide protection against UV rays, rain, snow, and other environmental elements. Additionally, FRP panels are easy to install, require minimal maintenance, and have a long lifespan. They also come in various colors and styles, allowing you to choose a design that complements your shed's aesthetics. Overall, FRP roofing panels are a practical and cost-effective solution for shed construction.

- Q: Can FRP roofing panels be used for soundproofing?

- FRP roofing panels excel at safeguarding buildings against weather conditions and maintaining their structural integrity. Although they do provide a certain level of insulation, their primary function is not soundproofing. Achieving soundproofing requires materials that can effectively absorb, dampen, or obstruct sound waves. In contrast, FRP roofing panels tend to be thin and lightweight, which means they may not possess sufficient soundproofing capabilities. To effectively soundproof a space, it is recommended to utilize specialized materials like acoustic panels, mass-loaded vinyl, or sound reduction insulation products. These materials are specifically engineered to absorb or obstruct sound waves, resulting in a quieter and more serene environment. In conclusion, while FRP roofing panels may offer some insulation against sound, they are not explicitly designed for soundproofing. If you desire to reduce noise levels, it is advisable to explore other soundproofing materials that are better suited for this purpose.

- Q: Do FRP roofing panels meet building codes and regulations?

- Yes, FRP (Fiberglass Reinforced Plastic) roofing panels typically meet building codes and regulations. However, it is important to verify specific requirements with local building authorities as codes can vary between jurisdictions.

- Q: Are FRP roofing panels resistant to solvents?

- Generally, solvents do not affect FRP (Fiberglass Reinforced Plastic) roofing panels due to their composition, which combines fiberglass and a plastic resin matrix. The fiberglass provides strength and stability, while the plastic resin offers resistance to various chemicals, including solvents. However, it is important to consider that the resistance of FRP roofing panels to solvents may vary depending on the type and concentration of the solvent used. While most common solvents will not harm FRP panels, aggressive solvents or prolonged exposure to certain chemicals can lead to material degradation or discoloration. To ensure compatibility between the FRP roofing panels and the solvents you plan to use, it is advisable to consult the manufacturer or supplier. They can provide specific information and guidance regarding the panels' resistance to the solvents and chemicals relevant to your application.

- Q: Are FRP roofing panels resistant to graffiti or marker stains?

- FRP roofing panels are generally resistant to graffiti or marker stains due to their smooth and non-porous surface. This surface makes it difficult for paint or markers to stick to the material. In addition, FRP panels are often treated with a protective coating that enhances their resistance to stains and graffiti. However, it is important to remember that no material is completely immune to graffiti or marker stains. If graffiti or marker stains do occur, it is recommended to promptly clean them using appropriate cleaning methods and products designed for FRP surfaces. It should be noted that repeated or aggressive attempts at graffiti removal may cause damage to the surface of the FRP panel.

- Q: Are FRP roofing panels resistant to discoloration?

- Indeed, FRP (Fiberglass Reinforced Plastic) roofing panels usually exhibit resistance to discoloration. These panels are made by combining fiberglass and plastic resins, resulting in impressive resistance against UV radiation and weather deterioration. Consequently, they have a reduced likelihood of fading or discoloring when exposed to sunlight or other environmental elements over an extended period. Nevertheless, it is worth mentioning that the degree of discoloration resistance may differ based on the particular brand and quality of the FRP roofing panel. Consistent cleaning and maintenance can also contribute to maintaining their appearance and preventing potential discoloration.

- Q: Can FRP roofing panels be used for both residential and commercial patio covers?

- Yes, FRP (Fiberglass Reinforced Plastic) roofing panels can be used for both residential and commercial patio covers. FRP roofing panels are durable, lightweight, and highly resistant to weathering, making them suitable for a wide range of applications. They offer excellent protection against UV rays, rain, and other weather elements, making them ideal for outdoor structures like patio covers. Additionally, FRP panels are available in a variety of colors and styles, allowing for customization to match the aesthetic requirements of both residential and commercial spaces. Whether it's a small residential patio cover or a large commercial outdoor seating area, FRP roofing panels can provide a sturdy and long-lasting solution.

- Q: Can FRP roofing panels be used for noise insulation?

- FRP roofing panels have some capability for noise insulation, although their primary purpose is durability, weather resistance, and light transmission. Their composition and design contribute to a certain level of sound insulation due to the noise-dampening properties of fiberglass. However, it's important to acknowledge that FRP panels alone may not provide the same level of noise insulation as specialized acoustic materials. The extent of noise reduction will depend on factors like panel thickness, design, noise frequency, intensity, and building construction. For optimal noise insulation, it may be advantageous to consider additional measures. These may include installing acoustic insulation materials, using double glazing for windows, or employing other soundproofing techniques alongside FRP roofing panels. Seeking guidance from a professional or acoustic engineer can help determine the most suitable and effective noise insulation solutions for your specific requirements.

- Q: Can FRP roofing panels be used for architectural applications?

- FRP roofing panels are indeed suitable for architectural applications, offering numerous advantages. Firstly, their lightweight and easy-to-handle nature makes them perfect for a variety of architectural projects. Architects can effortlessly install and manipulate them into different shapes and sizes, enabling the creation of unique and captivating designs. Secondly, FRP panels are highly durable and resistant to harsh weather conditions, including extreme heat, rain, snow, and UV radiation. This durability ensures that architectural structures constructed with FRP panels remain intact and visually appealing for extended periods. Additionally, architects have a wide range of options when it comes to FRP panels. They are available in various colors, finishes, and textures, allowing architects to achieve their desired aesthetic appearance. Regardless of whether the design is modern, industrial, or traditional, FRP panels can be customized to match the architectural vision. Moreover, compared to other materials used in architectural applications, FRP panels are cost-effective. Their lower installation and maintenance costs make them an attractive option for architects working within a budget. Lastly, FRP panels offer excellent thermal insulation properties, contributing to energy efficiency in buildings. By reducing heating and cooling costs, they promote environmental friendliness and sustainability. In conclusion, FRP roofing panels are a suitable choice for architectural applications. Their lightweight nature, durability, versatility, aesthetic options, cost-effectiveness, and thermal insulation properties make them reliable and visually appealing roofing solutions for architects.

Send your message to us

High strength Transparent corrugated FRP/GRP panel

- Loading Port:

- China main port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 100 kg

- Supply Capability:

- 100000 kg/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords