FRP Roofing Panel - Color Coated Metal Roof FRP Corrugated Roofing

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 200 m

- Supply Capability:

- 50000 m/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

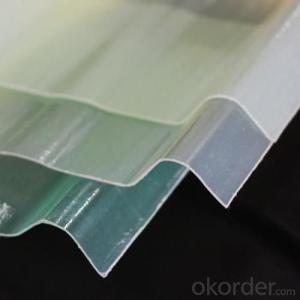

PRODUCT DESCRIPTION

Fiberglass corrugated sheet is usually used in construction site as protecting facility. It is dagarous for workers in building site since you never know if there is something hard drop down from the high area. So corrugated sheet is installed for preventing the stuff dropping down to hurt people.

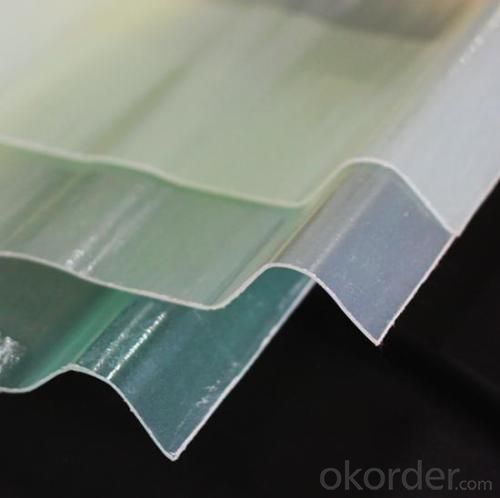

FRP GRP Fiberglass Glassfiber Corrugated Roofing is a patent of our company, not like other FRP products, it is produced without yarn, instead, we use mat only. Therefore, the corrugated sheet is more strong in both horizontal and vertical direction.

Fiberglass corrugated sheet is usually used in construction site as protecting facility. It is dagarous for workers in building site since you never know if there is something hard drop down from the high area. So corrugated sheet is installed for preventing the stuff dropping down to hurt people.

Besides, it could also applied as the roof of the constructions.

FEATURES

a. anti-corrosion, non-rusty

b. lightweight and high strength

c. anti-flammable

d. anti-fatigue

e. anti-slippery and safety

f. anti-ageing

g. easy to installation and maintenance

h. excellent electromagnetism property

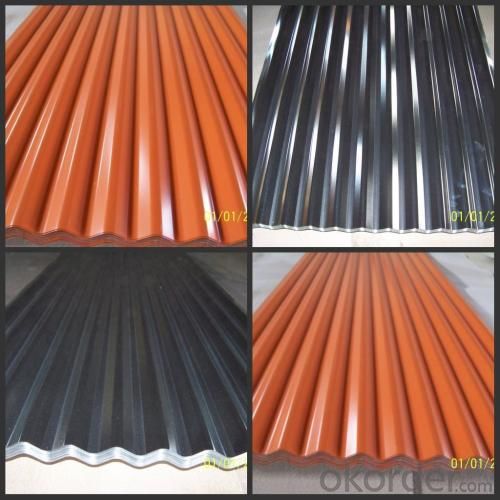

SPECIFICATIONS

Name: | FRP Roofing |

Material: | Fiberglass |

Width: | 880mm/1050mm |

Effective width: | 800mm/960mm |

Wave length: | 160mm |

Wave height: | 30mm |

Pitch: | 220mm |

Thickness: | 3/2.5mm |

Length: | Customized but must be a multiple of wave pitch |

Color: | Purplish Red, Brick Red, Grey, Green, Blue or customized |

Application: | House, villa, pavilions, industrial plants, large warehouses, supermarkets, stadiums etc |

MOQ: | 1000 Square meter |

PICTURES

- Q: Can FRP roofing panels be used for covered walkways in schools or universities?

- Yes, FRP (Fiber Reinforced Plastic) roofing panels can be used for covered walkways in schools or universities. FRP roofing panels are lightweight, durable, and have excellent resistance to weathering, making them suitable for outdoor applications. They are also easy to install and maintain, making them a practical choice for covered walkways. Additionally, FRP panels are available in various colors and designs, allowing schools and universities to choose options that match their aesthetic preferences. Overall, FRP roofing panels provide a cost-effective and reliable solution for creating covered walkways in educational institutions.

- Q: Are FRP roofing panels suitable for university campuses or educational buildings?

- Yes, FRP roofing panels are suitable for university campuses or educational buildings. FRP (Fiberglass Reinforced Plastic) roofing panels offer numerous benefits such as durability, lightweight construction, resistance to extreme weather conditions, and low maintenance requirements. These factors make FRP roofing panels a reliable and cost-effective choice for educational institutions seeking long-lasting and sustainable roofing solutions.

- Q: Can FRP roofing panels be installed on curved or domed roofs?

- Yes, FRP (Fiberglass Reinforced Plastic) roofing panels can be installed on curved or domed roofs. These panels are flexible and can be bent or curved to fit the desired roof shape. This makes them a suitable choice for unconventional roof designs or structures with curved or domed roofs.

- Q: Are FRP roofing panels suitable for high wind areas?

- Indeed, high wind areas can indeed accommodate FRP (Fiberglass Reinforced Plastic) roofing panels. Renowned for their remarkable robustness and longevity, FRP roofing panels display a notable resistance against fierce winds. The fiberglass reinforcement embedded within the panels enhances their structural integrity, enabling them to withstand the vigorous impact of high winds unscathed and undisturbed. Moreover, FRP roofing panels are intentionally engineered to be securely fastened to the roof framework, thereby bolstering their capacity to withstand wind uplift and retain their integrity when confronted with high wind conditions.

- Q: Are FRP roofing panels easy to repair?

- Yes, FRP (Fiberglass Reinforced Plastic) roofing panels are relatively easy to repair. The lightweight and durable nature of FRP panels make them simple to handle and work with during the repair process. Additionally, FRP panels are resistant to corrosion, mold, and mildew, which reduces the likelihood of extensive damage requiring repair. The repair process for FRP roofing panels typically involves cleaning the damaged area, removing any debris or loose material, and applying a suitable patching material or adhesive to seal the damaged section. This can be done by a homeowner or a professional contractor, depending on the extent of the damage and the individual's level of expertise. It is worth noting that the ease of repair may vary depending on the specific type and brand of FRP panel used. Some manufacturers may offer specific repair kits or instructions for their products, which can further simplify the repair process. Overall, with proper maintenance and timely repairs, FRP roofing panels can provide long-lasting protection for a wide range of applications.

- Q: Can FRP roofing panels be installed on both residential and commercial pergolas?

- FRP roofing panels are suitable for installation on both residential and commercial pergolas. They are a multipurpose roofing material that can be utilized in a variety of settings, including pergolas. Lightweight, durable, and resistant to weather elements such as UV radiation, rain, and wind, FRP panels offer several advantages. Whether it is a residential or commercial pergola, FRP panels bring numerous benefits. They are easy to install, resulting in reduced labor and time costs. Furthermore, homeowners or businesses can choose from a range of profiles, colors, and patterns to match their preferences or branding. In addition, FRP roofing panels allow for excellent natural light transmission, reducing the need for artificial lighting during daylight hours. This feature proves especially advantageous for commercial pergolas used for outdoor seating areas or events, creating a pleasant ambiance for customers. In summary, FRP roofing panels are an excellent choice for both residential and commercial pergolas due to their durability, aesthetic appeal, and ease of installation.

- Q: Can FRP roofing panels be used for carports or garages?

- Yes, FRP (Fiberglass Reinforced Plastic) roofing panels can definitely be used for carports or garages. FRP panels are known for their durability, strength, and resistance to corrosion and weathering, making them an excellent choice for these structures. They are lightweight, yet sturdy enough to withstand various weather conditions, including heavy rain, snow, and extreme temperatures. Additionally, FRP panels are easy to install and maintain, providing a cost-effective and long-lasting solution for carports and garages.

- Q: Can FRP roofing panels be used for shopping malls?

- Yes, FRP roofing panels can be used for shopping malls. They are a durable and lightweight roofing solution that can provide protection from weather elements while allowing natural light transmission. FRP panels are also resistant to corrosion, UV rays, and fire, making them suitable for commercial buildings like shopping malls.

- Q: Can FRP roofing panels be used for both interior and exterior applications?

- Both interior and exterior applications can indeed make use of FRP (Fiberglass Reinforced Plastic) roofing panels. These panels possess great versatility and can be applied in a variety of settings, including residential, commercial, and industrial spaces. For exterior purposes, FRP roofing panels are commonly utilized in roofing systems for buildings, garages, sheds, and other structures. They are renowned for their durability, resistance to weather, and ability to withstand harsh environmental conditions such as extreme temperatures, UV radiation, and moisture. Moreover, FRP panels are lightweight, making installation a more convenient and simple process. In terms of interior applications, FRP roofing panels are often employed in areas that require a high level of resistance to moisture, such as bathrooms, kitchens, and swimming pool enclosures. These panels are resistant to moisture and do not support the growth of mold or mildew, making them particularly suitable for environments with high levels of humidity. They are also easy to clean and maintain, which is of great importance for areas prone to spills or stains. Furthermore, FRP roofing panels can be utilized in both vertical and horizontal applications. They can be installed as wall cladding or partitions, providing a durable and aesthetically pleasing solution. With a wide range of colors, finishes, and textures available, FRP panels can be customized to meet specific design requirements, ultimately enhancing the overall appearance of the interior or exterior space. However, it is crucial to note that the selection of FRP roofing panels should be based on the specific requirements of the intended application. Factors such as load-bearing capacity, fire resistance, and intended use must be taken into consideration to ensure that the panels are suitable for the intended purpose. It is advisable to consult with a professional or manufacturer to determine the appropriate FRP roofing panels for a particular project.

- Q: Are FRP roofing panels resistant to wind damage?

- Yes, FRP (Fiberglass Reinforced Polymer) roofing panels are generally resistant to wind damage. They are designed to withstand high winds and are often tested and rated for specific wind speeds. The strength and durability of FRP panels make them less susceptible to wind-related issues such as tearing, cracking, or detachment, making them a reliable choice for buildings in areas prone to strong winds.

Send your message to us

FRP Roofing Panel - Color Coated Metal Roof FRP Corrugated Roofing

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 200 m

- Supply Capability:

- 50000 m/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords