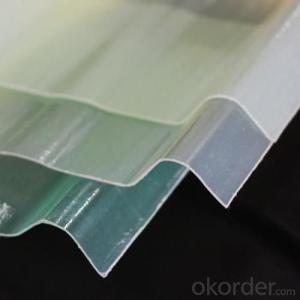

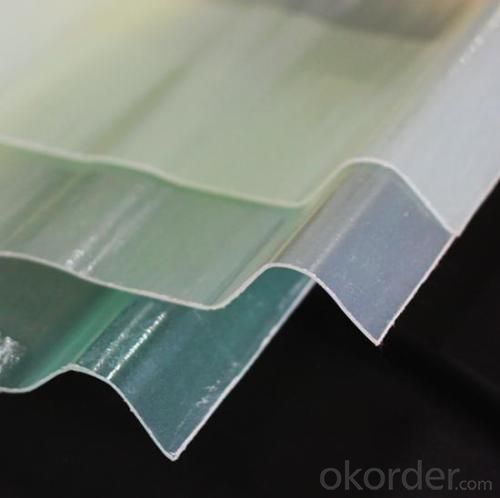

Translucent Fiberglass Roofing Sheets, Corrugated Fiberglass Roof

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 300 m

- Supply Capability:

- 30000 m/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

PRODUCT DESCRIPTION

Fiberglass corrugated sheet is usually used in construction site as protecting facility. It is dagarous for workers in building site since you never know if there is something hard drop down from the high area. So corrugated sheet is installed for preventing the stuff dropping down to hurt people.

FRP GRP Fiberglass Glassfiber Corrugated Roofing is a patent of our company, not like other FRP products, it is produced without yarn, instead, we use mat only. Therefore, the corrugated sheet is more strong in both horizontal and vertical direction.

FEATURES

1) The fiberglass content of new generation greenhouse panel has been improved by 18.3%.

2) Weather resistant and Self-clean ability.

3) Excellent yellowness resistance.

4) Strong impact resistant and low bending rate.

5)Withstand extreme temperature from -38 degree to +110 degree for a long time

6) Aging resistant: specified F4 film added on surface and gel coat makes it endurable for long.

7) More strengthened, safer, cleaner and more economical greenhouse panel.

8) Mainly serve the big factory, warehouse, super markets and other steel-structured project.

SPECIFICATIONS

Name: | FRP Roofing |

Material: | Fiberglass |

Width: | 880mm/1050mm |

Effective width: | 800mm/960mm |

Wave length: | 160mm |

Wave height: | 30mm |

Pitch: | 220mm |

Thickness: | 3/2.5mm |

Length: | Customized but must be a multiple of wave pitch |

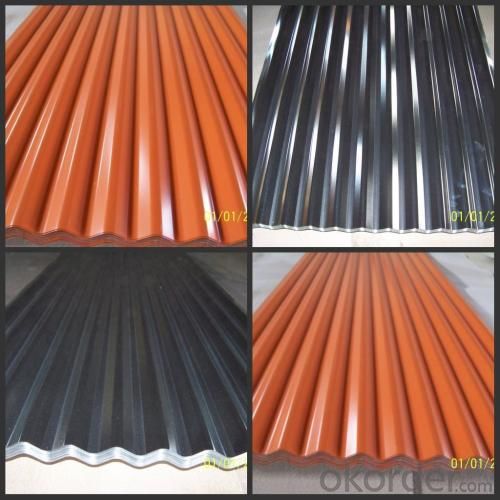

Color: | Purplish Red, Brick Red, Grey, Green, Blue or customized |

Application: | House, villa, pavilions, industrial plants, large warehouses, supermarkets, stadiums etc |

MOQ: | 1000 Square meter |

PICTURES

- Q: Do FRP roofing panels require any specific type of sealant or adhesive for installation?

- Yes, FRP roofing panels typically require a specific type of sealant or adhesive for proper installation. It is important to use a sealant or adhesive that is compatible with FRP materials to ensure a strong bond and long-lasting performance.

- Q: Are FRP roofing panels resistant to insects?

- Yes, FRP (Fiberglass Reinforced Plastic) roofing panels are generally resistant to insects. The composition of FRP panels, which typically consist of a fiberglass mat embedded in a polymer resin, creates a surface that insects find unappealing. Unlike traditional roofing materials such as wood, which can be susceptible to insect infestations, FRP panels do not provide a food source or a suitable habitat for insects. This makes FRP roofing panels highly resistant to damage or degradation caused by insects, ensuring the longevity and durability of the roofing system. However, it is important to note that while FRP panels are resistant to insects, they are not completely impervious. In extremely rare cases, certain types of insects with specialized feeding habits or aggressive behaviors may still be capable of causing minor damage to FRP panels. In such cases, timely inspections and appropriate pest control measures should be taken to prevent any potential issues.

- Q: Are FRP roofing panels suitable for residential balconies or terraces?

- FRP roofing panels are indeed a suitable option for residential balconies or terraces. These panels possess remarkable durability and weather resistance, making them an ideal choice for outdoor use. Their lightweight yet strong nature not only facilitates installation but also minimizes strain on the structure. Furthermore, FRP panels exhibit resistance against UV rays, chemicals, and corrosion, guaranteeing long-lasting performance and minimal maintenance. Additionally, they offer exceptional insulation, effectively regulating the temperature on balconies or terraces. In conclusion, FRP roofing panels represent a dependable and economical alternative for residential balconies or terraces.

- Q: Are FRP roofing panels suitable for commercial applications?

- FRP roofing panels are well-suited for commercial use. They are a popular choice for commercial buildings because of the many advantages they offer. Firstly, they are lightweight and durable, making them able to withstand harsh weather and heavy loads without compromising their structure. This makes them perfect for commercial buildings that require durability. Furthermore, FRP roofing panels are resistant to UV rays, corrosion, and chemicals, making them ideal for commercial applications where exposure to these elements is common. Their resistance also means that they require minimal maintenance, which lowers long-term costs for commercial building owners. Moreover, FRP roofing panels have excellent insulation properties, which helps with energy efficiency and reduces heating and cooling expenses for commercial buildings. This is particularly beneficial for commercial applications that require climate control in large areas. Finally, FRP roofing panels offer design flexibility, as they come in various colors, textures, and profiles. This allows commercial building owners to select a roofing system that meets their aesthetic preferences while still providing the necessary functionality. In conclusion, FRP roofing panels are an outstanding choice for commercial applications because of their durability, resistance to UV rays and chemicals, energy efficiency, low maintenance requirements, and design flexibility.

- Q: Can FRP roofing panels be used for sheds?

- Yes, FRP roofing panels can be used for sheds. FRP (Fiberglass Reinforced Plastic) roofing panels are lightweight, durable, and have excellent resistance to weathering and UV rays. These qualities make them suitable for sheds as they provide a long-lasting and low-maintenance roofing solution. Additionally, FRP panels are easy to install and offer good insulation properties, making them a practical choice for shed construction.

- Q: Can FRP roofing panels withstand extreme weather conditions?

- Yes, FRP (Fiberglass Reinforced Plastic) roofing panels are known for their durability and ability to withstand extreme weather conditions. One of the key advantages of FRP roofing panels is their high impact resistance, which allows them to withstand strong winds, heavy rain, hail, and even extreme temperature fluctuations. FRP panels are made of a composite material that combines fiberglass and resin, providing them with excellent strength and resilience. Furthermore, FRP panels are also UV resistant, which means they can withstand prolonged exposure to sunlight without fading or degrading. Overall, FRP roofing panels are designed to endure harsh weather conditions, making them a reliable choice for various applications.

- Q: Are FRP roofing panels resistant to chemical exposure in industrial environments?

- Yes, FRP (Fiberglass Reinforced Plastic) roofing panels are generally highly resistant to chemical exposure in industrial environments. FRP panels are known for their excellent corrosion resistance and can withstand exposure to a wide range of chemicals, including acids, alkalis, solvents, and fuels. They are commonly used in industrial settings such as chemical plants, refineries, and manufacturing facilities where there is a high risk of chemical exposure. FRP panels are designed to be chemically inert, meaning they do not react with or degrade in the presence of chemicals. This resistance to chemical exposure makes FRP roofing panels a durable and reliable choice for protecting industrial buildings and equipment from the potentially damaging effects of chemical substances. However, it is important to note that the specific performance of FRP panels may vary depending on the type and concentration of chemicals involved, so consulting with the manufacturer or a professional in the field is advised for specific application requirements.

- Q: Can FRP roofing panels be used for restaurants?

- Yes, FRP (Fiberglass Reinforced Plastic) roofing panels can be used for restaurants. FRP panels are lightweight, durable, and have excellent resistance to corrosion and UV radiation. These characteristics make them ideal for use in food establishments where hygiene, safety, and longevity are crucial. Additionally, FRP panels are easy to clean and maintain, which is essential for restaurants where cleanliness is a top priority. They also offer good insulation properties, helping to regulate temperature and reduce energy consumption. Overall, FRP roofing panels are a suitable choice for restaurants due to their durability, low maintenance requirements, and ability to meet the specific needs of the food industry.

- Q: Are FRP roofing panels resistant to corrosion from saltwater or chemicals?

- Yes, FRP (Fiberglass Reinforced Plastic) roofing panels are highly resistant to corrosion from saltwater and chemicals. The composition of FRP panels includes a combination of fiberglass and a resin matrix, which provides excellent resistance against corrosion. This makes FRP roofing panels ideal for installations in coastal areas or industrial environments where exposure to saltwater or chemicals is common. The non-reactive nature of the fiberglass and resin materials ensures that the panels remain durable and unaffected by the corrosive properties of saltwater or chemicals, extending their lifespan and reducing maintenance requirements. Furthermore, FRP panels are also resistant to UV radiation, impact, and extreme weather conditions, making them a reliable choice for various applications.

- Q: Are FRP roofing panels suitable for hospitals?

- Yes, FRP (Fiberglass Reinforced Plastic) roofing panels are suitable for hospitals. They are lightweight, durable, and resistant to corrosion, making them an excellent choice for healthcare facilities. FRP panels also offer good insulation properties and can withstand harsh weather conditions. Additionally, they are easy to clean and maintain, which is crucial in a hospital environment where hygiene is of utmost importance.

Send your message to us

Translucent Fiberglass Roofing Sheets, Corrugated Fiberglass Roof

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 300 m

- Supply Capability:

- 30000 m/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords