Throttle Choke Valves with API 6A Standard

- Loading Port:

- Tianjin

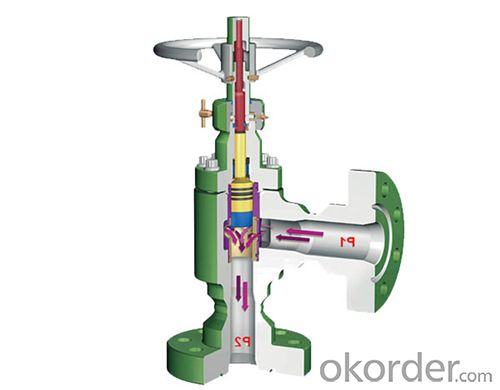

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 3 pc

- Supply Capability:

- 800 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

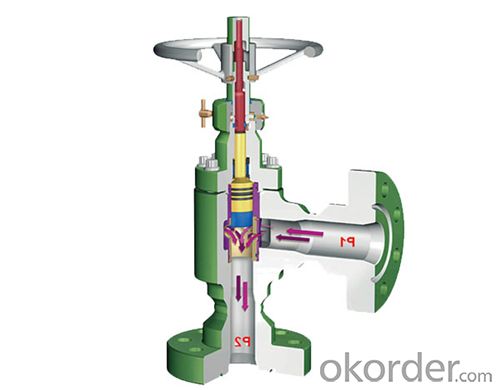

1. Structure of Throttle Choke Valves Description

1) Hole in Bonnet Nut to facilitate venting of pressure

2) Forged bonnet nut with lugs

3) H2 Classic prevents bonnet seal extrusion by means of body-to bonnet contact behind the O-ring seal

4) The bleed valve allows safe venting of the body cavity pressure

5) H2 is designed and manufactured in accordance with API 6A,including performance verification testing for PR2 level chokes

6) Forged body

2. Main Features of Throttle Choke Valves

1) API Standard

2) High quality and fast delivery

3) Easy operation and maintenance

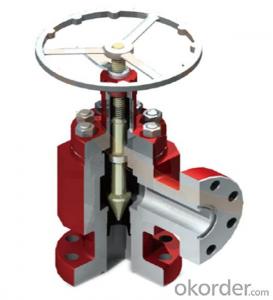

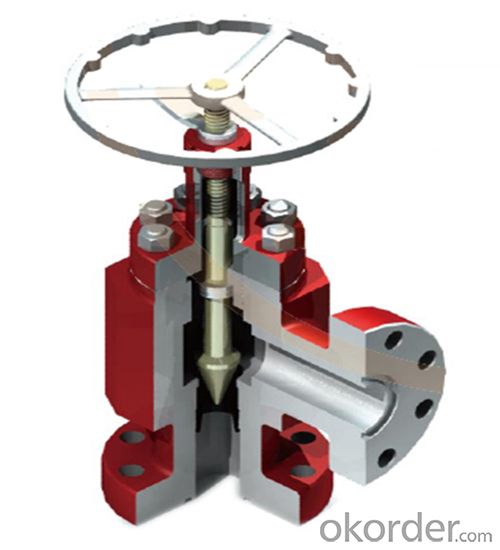

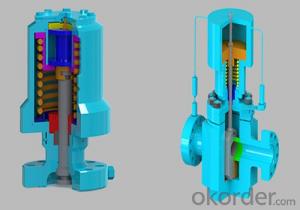

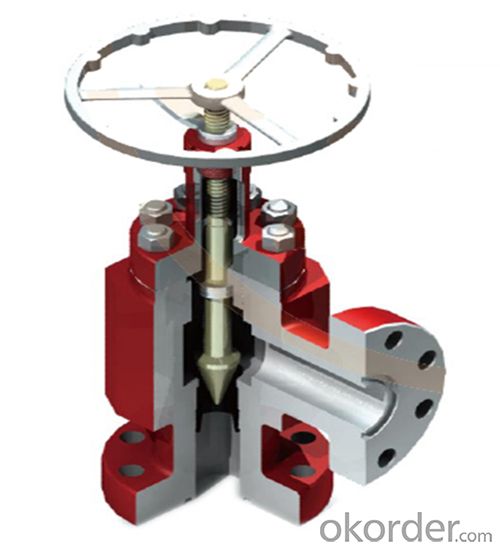

3. Throttle Choke Valves Images

4. Throttle Choke Valves Specification

Working Pressure :3,000Psi~20,000Psi

Nominal Bore :2-1/16"~4-1/16"

Working Temp :KU (-60℃~121℃)

Working medium:oil, gas, water, mud

PSL Class :PSL1~4

PR Class :PR1~2

Material Class :AA~HH

Actuator:Manual, hydraulic

End Connection:Conform to ANSI and API

5. FAQ of Throttle Choke Valves

We have organized several common questions for our clients,may help you sincerely:

①How about your company?

One of the leading manufacturers and suppliers specializing in Values products in China, can offer series of values to around the world.

②How to guarantee the quality of the products?

We have established the international advanced quality management system,every link from raw material to final product we have strict quality test;We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance.

③How long can we receive the product after purchase?

In the purchase of product within three working days, We will arrange the factory delivery as soon as possible.

- Q: I was told Wed. that I need to have my aortic valve replaced. I was wondering if anyone could share their experience with this surgery good or bad. I am meeting with the surgeon on the 26th, and am very nervous. Any tips and or suggestions appreciated. I'm a 39 year old female.Thanks in advance

- Hello Lisa, Aortic valve replacement is a cardiac surgery procedure in which a patient's aortic valve is replaced with a different one. The procedure itself is rather simple. Your chest will be opened, you will be placed on bypass, valves exchanged, and closed again. The risk with respect to the procedure is generally cited as being between 1 and 5 percent. My advice to you is to call ahead, and specifically request to meet the physicians who will be performing surgery; including the Senior Surgeon, and Anaesthesiologist. In some cases, hospitals will provide a general doctor for questions; but it is important to meet all of those who will be operating, both for comfort and questions. When meeting with those who will be operating on you; ask them any questions you might have. They are there for you; to brief you on the procedure, ensure you are ready, and respond to any of your concerns. Dr. James Jeah MD

- Q: Model 28 BS 12.5 HP engine intake valve sticks. Please advise.When under a full load like tall grass, it runs great, but when the load is not as heavy, the intake valve sticks open, spewing gas back through the carb and mis-firing.

- Weird that it runs better under load. Try spraying carb cleaner into the carb while it's running to see if it can remove some carbon build-up or whatever might be causing the lifter to stick. Be careful about how much you spray..too much and the engine will shut off. Spray it until it sputters, let it recover, then spray some more. Check the spark plug. A badly fouled, improperly gapped plug can cause similar problems. Of course clean/replace the air filter.

- Q: where are the proportion valves located on a 1991 buick skylark?

- definite they do pass undesirable! It sounds like this is your difficulty. you are able to attempt bleeding the proportioning valve with a brake bleeding gun, making optimistic to open each valve then re-bleed the brake gadget this would get rid of the potential for a air bubble in the proportioning valve. I even have replaced probable ten or twelve of those issues in my ventures.

- Q: school starts tomorrow that means having band and i havent played it in 2 months (summer vacation) and i oiled the valves and the 1 and 2 valves are stuck the 1st valve comes up slowly when i push it down but on the 2nd valve it stays down how do i undo this???? thank you

- Unscrew your valve, remove the bottom valve cap, and carefully push out the valve with a drumstick or something. Clean the valve off with a cotton swab and some vinegar, rinse it off gently with lukewarm water, oil 'er up, and put her back in. If you've messed your instrument up to the point where your valve caps are all stuck from lack of cleaning, you're going to have to take it to a professional. Don't force them with a tool or anything or you'll strip them. Haha, good luck. Matt

- Q: Hey I'm high rite now and i have a checkup for mitro-valve prolapse tomrow, i was wondering if they will take my blood and see THC in me....

- Mitral okorder

- Q: I mean dropping the valve seat. And some mechanic told me that it dropped when the catalytic converter got clogged and it hurt the engine. But the most I've heard is that if I want to avoid this from happening I should be running the engine a bit colder because the valves weren't made with the right specs and after a 100,000 miles they become a bit loose and when the engine gets to the normal temperature or just a bit above, the valve seats would drop. Does ANYONE KNOW ANYTHING ABOUT THIS?

- If the valve has dropped you will hear a ticking nose when the engine is running. It the valve hitting the piston. This need to be fixed ASAP, With a stuck valve you will experance back firing or lots of smoke could out of the tall pipe especially on acceleration. Either way if you are trying to keep your car I would have the problem correctly diagnosed and this will likely means you will need a top end rebuild. These little 1.9L ford engines were pretty tough but after XX amount of miles and so many years it time for some internal engine work.

- Q: Offcourse temp control valve controls temp, and pressure control valve controls pressure....and so on. I am wondering, what are the mechnical differences in the valves body and how are they operated in terms of process control.

- In principle all valves are flow control valves. What changes is the variable they are controlling. A temperature control valve controls a flow to heat or cool another fluid. A pressure control valve, controls a flow to maintain the pressure in a vessel. As pointed earlier, valves can be self contained, i.e., the sensor is part of the control mechanism, usually a diaprhagm which moves the valve stem. and a spring to adjust a set point. Or, they can be pneumatic or electronic, in which case there is an external power source, transducer and controller to adjust set point, gain, reset and rate. This gives additional flexibility, if needed, depending on the process to be controlled. .

- Q: what to use to inflate self sealing tube with the presta valve?

- Gazoo If you do not have a pump that will accept a presta valve, then you can either buy a presta schrader pump, or a presta valve adapter. I have an adapter in each of my seat bags, they are only a buck or so, and will allow you to use service station air on your trips. Just cause you may not know, the presta valve has a rotating screw inside the valve. So to add or release air you must take your fingers and twist on that knurled circular end so that the presta valve extends away from the valve stem. Then when the tube is filled, twist it back tight to seal it off. Soccerref

- Q: I have a 99 Yamaha Warrior 350 and i am needing to take it and get the valves adjusted. I know prices will range from state to state but what would be the average price to take and get them adjusted?? Just the valves not including if they had to change the seals or anything.. Thanks(PS im a girl so put it in simple words!)

- The mechanics charge about $40. But, you can learn to do it yourself it is easy. Just loosen the outer nut. Turn the center one til it touches. Then back it off 1/8th of a turn. Then while holding the center one tighten the outer nut. Then your done with that valve, and repeat for however many valves you have.

- Q: I don't know the principle of operation of the butterfly valve. Can I control the percentage of opening by an analog output from the PLC?

- A butterfly valve does not have an overall linear characteristic and is a poor modulation controller through its full range of operation. It will need a stout shaft and a tough actuator. It will be most linear in about the 30% to 60% open range. To make a full linear controller, you will need to have the actuator-controller- valve , single source supplier know what control feature you wish to accomplish in the fluid system and what the controlling signal will be. Any cotrol valve is a variable resistance added in the whole dynamic system which itself will have an inherent second order friction loss flow characteristic.

Send your message to us

Throttle Choke Valves with API 6A Standard

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 3 pc

- Supply Capability:

- 800 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords