Check Valve with API 6A Standard for Oilfield Usage

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 pc

- Supply Capability:

- 500 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

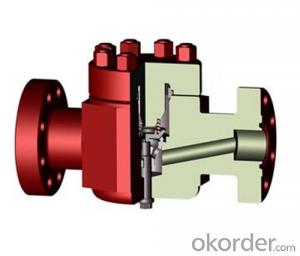

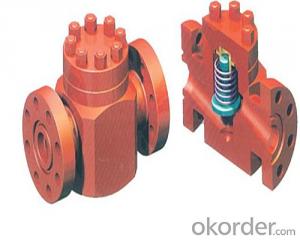

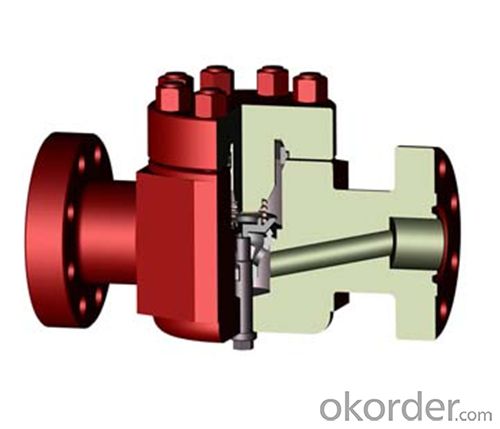

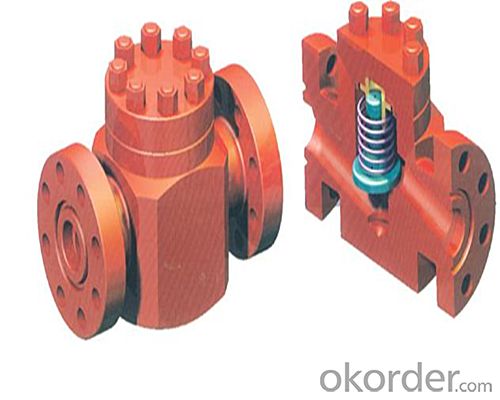

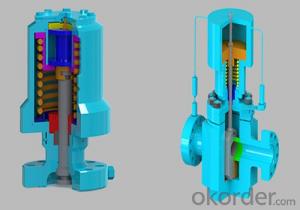

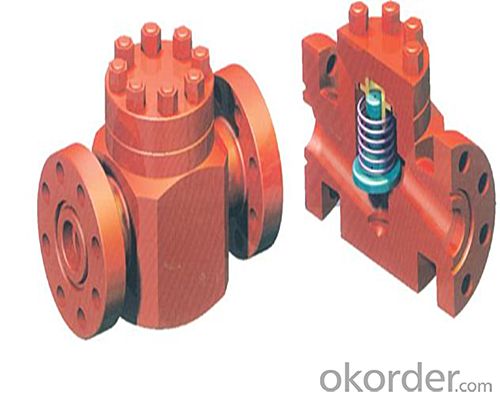

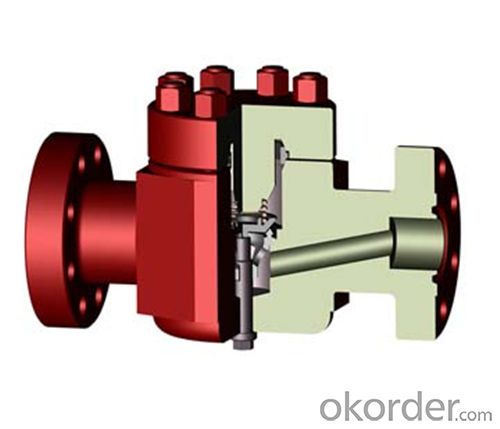

1. Structure of Check Valve Description

The design and production of the product completely meets the requirements of API Spec 6A: Wellhead and Christmas tree specification. In accordance with API Spec 6A specification form a complete set of equipment and used interchangeably at home and abroad.

2. Main Features of Check Valve

1) The valve is made by forging, that make it bear high-pressure.

2) The inner parts of valve is made of stainless steel, piston and disc seat covers nickel-based alloy , so it has a long working life without corrosion.

3) The special construction can avoid water hammer phenomenon.

4) The characteristic of the valve is that, good sealing performance, strong corrosion resistance, long service life, flexible switch and also can be used for regulating the flow.

3. Check Valve Images

4. Check Valve Specification

Working Pressure:2,000Psi~20,000Psi

Nominal Diameter:2-1/16 "~4-1/16 "

Working Temp. : KU (-60℃~121℃)

Working Medium:oil、gas、mud

PSL Class:PSL1~4

PR Class:PR1~2

Material Class:AA~HH

End Connection:API Spec connection

5. FAQ of Check Valve

We have organized several common questions for our clients,may help you sincerely:

①How about your company?

One of the leading manufacturers and suppliers specializing in steel pipe products in China, mainly offering four series steel pipes including welded steel pipe (ERW,

SSAW, LSAW and square and rectangle pipe), seamless steel pipe, hot dipped galvanized steel pipe and steel pipe with 3 layer polythene coating. We can provide

customers different specification standards e.g. ASTM A53, ASTM A106, BS1387, API 5L, API 5CT, ISO3183 and etc. Our scope of supplying covers from 1/2" to 48" for the

outside diameter of welded pipes, and 1/8" to 20" for the seamless pipes.

Other than steel pipes we are also capable of supplying a wide variety of pipeline accessories, steel pipe fittings; valves etc. consists of our one-stop sales. The

integrated sales & service ensures customers with various demands an easier access for purchasing management.

②How to guarantee the quality of the products?

We have established the international advanced quality management system,every link from raw material to final product we have strict quality test;We resolutely put

an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance.

③How long can we receive the product after purchase?

In the purchase of product within three working days, We will arrange the factory delivery as soon as possible.

- Q: Need some info. Ok, four valves per cylinder is better than two valves per cylinder. Fine, why did Ford REVERT to only 3 valves (my guess is to save cost SOHC)? Audi and VW are using five valves per cylinder on some cars, does this offer any advantage over a four valve engine? Maserati even experimented with a six valve per cylinder!!!! (see link) http://www.maserati-alfieri .uk/alfieri26.htm but abandoned it (my guess is cost again?) Why are we stuck at four valves or would more valves actually render more horsepower? Pop some ideas best answer to reasonable answer...

- The ideal situation would be to remove the head during the intake stroke and put it back on during the compression stroke, but, obviously, this isn't possible. On a naturally aspirated engine, the intake is the most critical because the air is moved only by a relatively small difference in pressures. The exhaust stroke, on the other hand, is aided greatly by the super heated temperature and rapid expansion of the gasses.

- Q: Serious answers only please. I have a 1995 Ford F-250 XL 5.8L 351 c.i. engine. My check engine light comes on periodically when I drive. When I bought the truck a year ago the gas mileage wasn't too bad, about 9-10 mpg. I've only put about 3,000 miles on it this past year, and now the needle drops just driving it across town. I work at a Chevy dealership, and I've worked at another Chevy dealer as well as a Ford. I've always done my own work on my cars and am currently restoring a 1967 Mustang, so I have decent knowledge under the hood. I scanned the truck and it has a stored code for EGR valve voltage too high (stuck open). How bad could this be hurting my gas mileage? It's $160 for the valve and sensor even after my discount, and being a college student that's a lotta $ to pay. I'm selling the truck and need it running perfect when I do. Please, serious answers only, and help is greatly appreciated!

- EGR valve should be opening at higher RPM's and closing at lower ones. Check the shaft positioin on the EGR valve with the engine idling (you might need a flashlight and mirror on an extension rod to see it on your vehicle). When the engine is revved up, the shaft should move away from the engine. If its not moving or it moves open but doesn't close all the way, it could be that the valve seat of the valve is broken and holding the valve open. If you do end up replacing it, clean out the carbon if there is any in the opening of the engine that leads to the EGR valve.

- Q: I have 06 Suzuki gsx-r 750 and i was wondering what are the signs or how do i know that my valves need to be adjusted?

- Actually, your valves will not clatter, they will get very quiet. Valve clearances ordinarily tend to tighten up over time. A tappy valve is a happy valve. Measure the clearances with a feeler gauge to tell if they need adjustment. Some early warning signs of tight valve clearances include an unstable idle, stalling on the overrun, and stumbling off idle. You should also keep a record of your clearances before adjustment, shim sizes as found, clearance after adjustment, shim sizes after adjustment, and mileage. That information will help you anticipate adjustments, give you an idea of what shim sizes to have on hand, and give you an indication of any unusual wear patterns. Keep this information in mind when chasing carb and ignition problems, too. Driveability issues attributed to carburetion are often caused by tight valve clearances instead. If it has been a while since your last valve adjustment, set them first, before chasing carb issues.

- Q: I've been told that I need to replace a clogged expanssion valve on my '96 toyota camry.A friend said he would properly recharge the system if i replaced the parts needed .I can't ask him where it is because he's out of town for a little while. I also need to replace the drier ,but it's obvious where it is.Please help me.

- the expansion valve is usually located inside the line next to the accumulator/dryer. If you drain the system, and remove the accumulator, look inside the line that leads into it, and it should be stuffed in the line. If you see one inside the line, it is actually called an orifice tube, but has the same function as an expansion valve. Actually, expansion valves are usually used in large vans with a rear a/c evaporator unit. If it is an external valve it should be next to the accumulator as well. The purpose of this valve/tube is to create high pressure gas out of low pressure liquid freon. These usually become clogged with debris after the compressor's pistons break apart and contaminate the system. If you find little metal shavings in the tube, or valve, your compressor was either replaced at one time, or is bad now.

- Q: Was wondering if there is something I could purchase to put into a car so that it will become a 24 valve????

- You'll just have to buy a vehicle that has a 24 valve engine man.

- Q: I have a 99 Yamaha Warrior 350 and i am needing to take it and get the valves adjusted. I know prices will range from state to state but what would be the average price to take and get them adjusted?? Just the valves not including if they had to change the seals or anything.. Thanks(PS im a girl so put it in simple words!)

- Did it run OK before changing the pipe jet? Install the stock parts to see if that clears up the problem. The jetting or needle height might be incorrect. Inspect the air cleaner. Contact me for a carburetor adjustment guide.

- Q: Can anyone tell me what to do if i know that I have the type of valve stem that was recalled TR413chrome?? Will they replace them for free since they are a recall or do I have to dish out some more $$ to fix the problem??? The company that sold them to me is in Florida (Wheelmax) and I am in Mass. Not sure what to do to avoid having to pay out more $$ to have them replaced...any help is greatly appreciated

- Get okorder Take care.

- Q: I have recently been diagnosed with Endometriosis within the last 2 years. I have also had Mitral Valve Prolapse (MVP) for the past 10 years. ... Anyways... I was reading in a brochure for Endometrosis that there is a commonality between having those two diseases. If you know of the reasoning behind this I would be very interested in knowing. As I have yet to find an answer yet. I am just curious why having one will give you a larger likley hood to get the other. Thanks for your time and answers!

- You okorder ). It's about how to eradicate endometriosis disease forever. It worked for me, you will see results in only a matter of weeks. Good Luck!

- Q: My friend is having 3 valves in her heart replaced with pig valves. Her dr said that putting in human valves raises the risk of her body rejecting them but wouldnt your body also reject a part form different species? And if they only last a few years why use them at all? shes all freaked out about the surgery so I dont want to ask her too many questions

- Hello again. The valve I have implanted in me is porcine. Pig valves are sometimes used for a few reasons. First of all, they are much easier to get a hold of. Waiting for a human valve can take a long time. Secondly, there is less risk of rejection. These two reasons make a porcine valve better than having a human valve. You can also have metal valves, but when you have one or more of these you must take crazy medications for your entire life. With porcine valves, no extra medications are needed. So, porcine valves are really the best option. Like I said in a previous answer to one of your questions, I had my surgery when I was 16. I'm 22 now and doing alright. My valve is expected to last 10-15 years, so I expect to go under the knife to have it replaced when I'm 26-31. Unfortunately I have other issues and will have to have the surgery done earlier, and they'll probably change the valve while they're in there already. As far as I know, porcine valves last just as long as human valves. Whichever you have, it's going to clog up eventually anyways.

- Q: I don't know the principle of operation of the butterfly valve. Can I control the percentage of opening by an analog output from the PLC?

- A okorder /... All of the control valves I have installed have been electric and used a 4-20ma to control the position of the valve. I used a Watlow controller to produce the 4-20ma. I use it to control the flow of chilled water for a process. I would contact tyco and tell them you are checking into prices and what it would take to run a 2 butterfly valve to control chilled water. I want it to be ran by an analog output from a PLC. They will be able to give you the information that you need. I hope this helps, Good Luck

Send your message to us

Check Valve with API 6A Standard for Oilfield Usage

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 pc

- Supply Capability:

- 500 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords