Fiber Cement Board with Both Sides Sanding Standard

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 600 pc

- Supply Capability:

- 20000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Products Introduction:

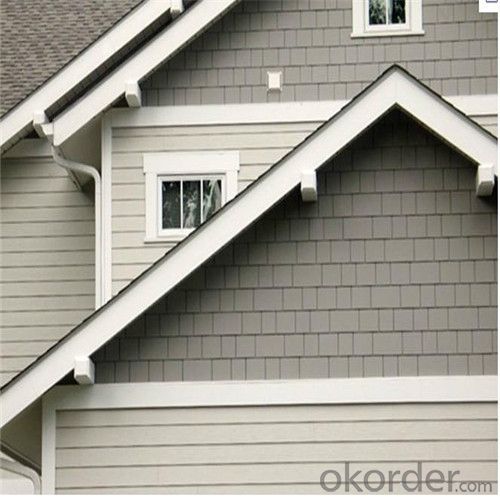

Our fiber cement board is made of high-grade cement and modified material, reinforced by natural fiber. Being processed by high pressure and high temperature advanced technologies, Sanle fiber cement board is a new building material with excellent performances.

Features

Fire Proof & Insulation

Class A non-inflammability, no toxic gas, low in perveance, good electric insulation material

Waterproof and Moisture Proof

In semi-outdoor area and under high temperature condition, performance of Sanle boards is stable and will not bend or deform.

Thermal Insulation and Sound Insulation

Low thermal conductivity, good heat insulation, high in density, sound proof

Light weight & High strength

Pressured by 5000-ton hydraulic machine, it is high in strength and light in weight. It is not easy to deform and bend, and good for flooring and roofing.

Easy installation

The installation of boards is dry operation, which is faster. It can be processed with ordinary wood working tool. The board is easy to be processed.

Economical and Good looking

The boards are light in weight. Together with the use of keels, they can save cost of construction and decoration. The painting is uniform, and the surface is smooth, making the exterior of buildings good-looking and attractive.

Safe and Harmless

Test result of Sanle boards is better than national radiation protection standards of building materials. The radiation from Sanle boards is equal to that from the lawn 20 meters away from the building. The lifespan of Sanle boards is very long, and they are resistant to acid and alkali, moisture and insects. The toughness and strength remains the same when time passes by. So they can be used for a long time.

Description:

(1) Lightweight and high strength: 3-4 kg/m2 (1/10 of half brick wall), with yield strength 400mpa.

(2) Environment-friendly : galvanized steel-no radiation, have no harm to our health and not pollute the environment.

(3) Products with fillisters : Setting some fillisters in both sides of the keels in a selective way, in order to strength the keels' vertical points and intensity.

(4) The metal stud with hole : one of our product is the special hole on C-stud every 600mm, which is easy for workers to install the electric lines and water tubes.

(5) Various sizes of metal track and metal stud : we are able to manufacture German,

(6) Factory direct sale price : We have our own factory to produce raw materials----galvanized(zinc coated) steel, as well as the product line, so we can provide you a lowest price.

FAQ

1.Sample: small sample can be offered by free

2.OEM: OEM is accepted

3.MOQ: small order is ok

4.Test: any third party is accepted to test

5.Factory: Can visit factory any time

6.Delivery Time: small order is within 7days or according to your order

- Q: What is the kind of plate?

- Good fire performance: As the amalgam cement board itself is not combustible, and the fire burning process will absorb a lot of heat, delay the ambient temperature rise, therefore, the United States rock cement board has a good fire retardant performance. Inspection and testing by the National Fire Equipment Supervision and Testing Center, the United States rock cement board wall fire resistance up to 8 hours. To achieve a level of fire, the gypsum board can only reach the fire three. Meishan cement board fire aging by CNS12514 wet two-hour fire aging test.

- Q: I want to put a small addition to the side of my concrete bungalow. it will be shed with lean to roof I want to construct this without having to put columns/post on the side of the house what I want to do is attach like a piece of 2x4 or 1x4 to the wall horizontally and have my rafter attached to it. the excisting concrete wall is made of 6 inch thick cinder blocksplease help

- You've already the answer/solution. A Ledger attached at the wall side, and some method of support at the outer edge of the roof.

- Q: Sound insulation board effect and what is relevant

- General noise is the practice of two types of materials used together, sealing plate with a high density of the plate, and the middle filled with sound-absorbing cotton, such as 50mm thick gradient of sound-absorbing cotton such a highly efficient sound-absorbing material. You can play a very good sound insulation effect.

- Q: Can the Etch board be used for the bathroom?

- Eide board in a damp place for a long time easy to mold, interface cracking, yellowing. I suggest you use a single brick wall, strong and durable. If you feel more blunt, you can use glass brick wall.

- Q: I would like to make my exterior walls more resistant against water and termites, so I would like to put cement boards instead of plywood boards before installing new vinyl siding. It costs a bit more but I think it would be worth it.

- It would cost double the amount of plywood .The nails won t hold good in just the cement board.When nailing into the cement board you may pound through the cement board if there is no wood support under it, but other than that there is no reason you couldn t. In other words I wouldn t suggest it. GL

- Q: can a double drywall wall be replaced with cement board or backer board?

- One layer can be replaced with a cement board and still be fire rated in most all areas. Using just one layer you can still be flush and use an SBN (surface bull nose) to trim it out. Any questions you can e mail me through my avatar and check my qualifications there. GL

- Q: Can I just paint a stone on a cemented fiberboard?

- Yes, as long as the cement surface to ensure the smoothness of the surface roughness and verticality can be directly sprayed. Cement fiberboard, also known as fiber cement board. Is based on siliceous, calcium material as the main raw material, adding plant fiber, after the pulp, copy, pressure, conservation made of a new type of building materials. After the high-pressure production of cement fiber board, also known as fiber cement pressure plate, its performance is better than the non-pressurized cement fiber board.

- Q: cost of installation per sq foot

- I used to charge 2.50$ a s/f for installing cement board. This would include the board, thin set to set it ( floors) and nails/ screws. Any questions you can e mail me through my avatar ..GL

- Q: i live in a country where houses are made with bricks..but i made my house just like in USA , but there is one only problem i need cement board to finish the bathroom , since we don't have cement board here for sale , and i can't afford import from USA , i was wondering that i can make it , i'm sure that i can make it , but i just need to know how to prepare de cement i would be appreciated if anyone help me thanks

- Surely you must be able to purchase something equivalent? If Wonderboard is not available, how about Hardibacker? Or Cembonit?

- Q: Is there a easy method to apply hydraulic water stop cement to the area where the wall meets the floor without making a mess. Thank you very much

- Yes and no. The good thing is that is dries really fast and you can use a wire brush to help clean the surrounding areas after filling the crack or hole. Just don't let the mix get to dry before using the wire brush. Also, when doing this, use the coldest water and it will cure more slower.

Send your message to us

Fiber Cement Board with Both Sides Sanding Standard

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 600 pc

- Supply Capability:

- 20000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords