Reinforced Fiber Cement Board

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Applications:

1. Excellent fire-proof performance

2. Excellent damp-proof performance .

3. Durability and long service life

4. CE

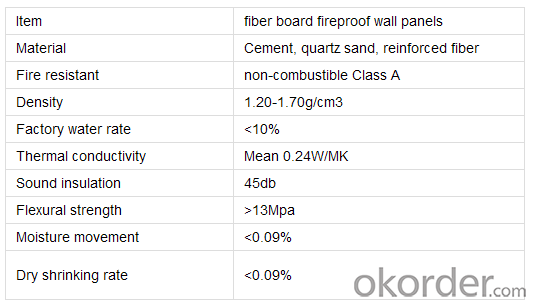

With quartz sand ,cement reinforce fiber as main raw mateirals ,cement board is a light board material made throught high temperature and high pressure maintenance , and special treatment .

Major Usage : Internal and external wall materials

Product Advantages:

1. Excellent fire-proof performance

2. Excellent damp-proof performance .

3. Durability and long service life

4. High strength

5. Good heat and sound insulation

Main Product Features:

1. 1220*2440*4-20mm

2. 1200*2400*4-20mm

3. 1220*3050*5-18mm

4. 1220*3660*5-18mm

Other sizes are selectable

Product Specifications:

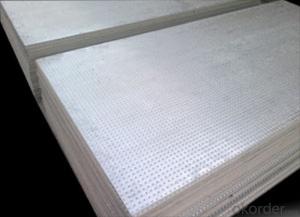

Images:

- Q: What is the process of using a cement pressure plate to dry the tile? What do I need to know about the specifications of the light steel keel, how thick the board

- Process: the traditional, inconvenient practice is to use the steel wire hanging and then wiping the cement leveling, and then use the wet paste tiles. My advice is to use tile adhesive paste directly tile, fast efficiency, and after the process of ditch groove beautiful, unlike the cement paste the black seam.

- Q: do I have to remove the vinyl floor covering or can I just put the cement board over it

- If it is only one layer of tile you can work right over it as long as the floor is leveled.

- Q: I'm removing a tile floor and planning to install a hardwood floor instead. I found cement backer board under the tile. Do I need to remove the cement backer board? Or can I install the hardwood on top of that?

- Nailing could be problematic. Nailing hardwood is done at an angle and the hardness of the cement board may cause the nails to deflect. Try it and see if it works.

- Q: How to apply waterproof material on the cement board?

- Plus a layer of geotextile and glue together with cement-based waterproof coating K11 or JS

- Q: Looking to connect a piece of plywood between two boards to hang a banner

- I am okay with the 5 gallons of concrete, that will weigh close to 100 lbs per bucket. I would use 1.5 - 2 inch pvc pipe, not 2x4's. That will give you better flex. For the banner, it is up so high that the wind loading and leverage will be a problem if you tie all four corners. So just connect the two poles with a rope at the top and hang the sign from the rope. This way in a wind, the bottom will just blow free. If you must tie the banner at 4 corners, you need a flatter container of concrete. An old tire, filled with concrete, will work for this purpose. Put a piece of plywood across the tire so it will hold the concrete. That's what we used for tether ball.

- Q: Can anyone suggest a good way to cut small pieces (i.e. 2-4) of Hardiebacker and make it break cleanly? I can't seem to get it to break off easily unless it's bigger piece... and I was told not to use a power tool (i.e. circular saw) as it would create a ton of dust, which could be bad to breath in.

- Wet backer board as you cut it..keep water away from electrical components of saw. Dust will no be minimal.....this is a 2 man job.

- Q: What are the differences between the gypsum board and the cement pressure plate and the Eide board?

- Ette board is a fiber reinforced silicate plate (fiber cement board), the main raw material is cement, selected minerals, by the high temperature autoclaved autoclaved, waterproof performance, can be used as toilet Wall, or outdoor roof roof, or external wall with the board can be in the long-term damp environment to maintain stable performance unchanged.

- Q: Replacing the cement board is not realistic, I don't know of anything that may be more flexible and not deteriorate so quickly.

- 100% Silicone Caulk - White.

- Q: am Laying Floor Tile and was Wondering if the Mesh Tape for Cement Board is the Same as you use for Drywall?

- It's similar, but wider. Hope this helps.

- Q: I know it sounds odd but if you set a cement block between to supports and hit it with your fist its really not hard at all to break it. Why is it that a 1 thick cement block breaks easier than a 1 thick piece of pine. Also it seems like maybe its just me but if you hit a 1 thick oak board your fist doesnt have to be in contact as long to break it. With the cement block it doesn't take much to make it break.

- condition the edge of the hand on an anvil for at least a year, then start with patio blocks. Blocks must be dry, new, and not painted.

Send your message to us

Reinforced Fiber Cement Board

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords