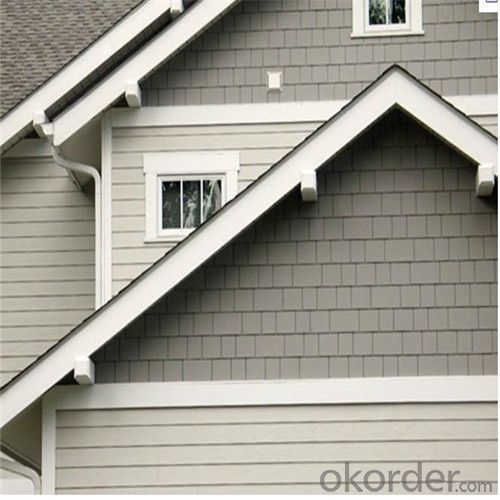

Two Sides Sanding Fiber Cement Board

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Products Introduction:

Sanle fiber cement board is made of high-grade cement and modified material, reinforced by natural fiber. Being processed by high pressure and high temperature advanced technologies, Sanle fiber cement board is a new building material with excellent performances.

Features

Fire Proof & Insulation

Class A non-inflammability, no toxic gas, low in perveance, good electric insulation material

Waterproof and Moisture Proof

In semi-outdoor area and under high temperature condition, performance of Sanle boards is stable and will not bend or deform.

Thermal Insulation and Sound Insulation

Low thermal conductivity, good heat insulation, high in density, sound proof

Light weight & High strength

Pressured by 5000-ton hydraulic machine, it is high in strength and light in weight. It is not easy to deform and bend, and good for flooring and roofing.

Easy installation

The installation of boards is dry operation, which is faster. It can be processed with ordinary wood working tool. The board is easy to be processed.

Economical and Good looking

The boards are light in weight. Together with the use of keels, they can save cost of construction and decoration. The painting is uniform, and the surface is smooth, making the exterior of buildings good-looking and attractive.

Safe and Harmless

Test result of Sanle boards is better than national radiation protection standards of building materials. The radiation from Sanle boards is equal to that from the lawn 20 meters away from the building. The lifespan of Sanle boards is very long, and they are resistant to acid and alkali, moisture and insects. The toughness and strength remains the same when time passes by. So they can be used for a long time.

Easy to install and easy to replace

Sanle boards can be drilled, cut, engraved, nailed, painted and covered by tiles or sticker when necessary..

Product parameters

Item | Unit | Requirement | ||||

Medium density | High density | |||||

Density | g/cm3 | 1.2<D≤1.5 | 1.5<D≤2.0 | |||

Water absorption | % | ≤30 | ≤25 | |||

Non-combustibility | GB 8624-2006, grade A | |||||

wet expansion | % | ≤0.25 | ||||

Beding strength | dry | MPA | Strength grade class III | 20 | Strength grade class IV | 24 |

Saturation with water | 12 | 14 | ||||

Applications

Exterior side boards, indoor partition walls, sound-proof ceiling, decoration boards, complex walls, outdoor billboards, division boards and floor boards

- Q: Can cement tiles be directly on the cement board? What material is good?

- Small area can be directly on the cement board with brick can be used. If it is a large area must be linked to the net brush paste and then tiling, so that will not crack off after the use of cement mortar.

- Q: Fiber reinforced silicate board which is good

- Pumai explosion-proof plate (fiber cement composite steel plate): Pumai explosion-proof plate using sandwich structure, the surface structure of 0.5mm hot-dip galvanized steel plate, the middle sandwich for the strengthening of fiber cement board, the surface plate is 20mm pitch, a total hit 5mm round hole, hole steel plate jagged, Deep into the cement layer, with high pressure will be closely integrated with the three, when the cement solidification into both steel and cement function of the super fire and explosion-proof plate. Mainly used in pharmaceutical plants, chemical plants, oil and other industrial buildings dangerous goods explosion-proof wall and explosion-proof ceiling.

- Q: in my new bath/shower i'm using hardibacker cement board. what should i use for the rest of the bathroom walls

- Listen to bascatman. The greenboard works great for damp areas.

- Q: I know I could hire someone with a curbing machine, but it is way more expensive than I want to pay and I want to do it myself so I can customize it to my yard. I've known people who have been able to do it themselves.What tools do I need?

- not a real easy diy job but have fun

- Q: My bathroom has a section where there is cement board. Over the cement board is a layer of plaster. Tiles were glued to the plaster. However, the plaster came off of most of the cement board over time. Of course, the tiles have fallen off too. So now I have bare cement board partially covered by plaster.I'd like to remove the remaining plaster from the cement board and then retile directly over the cement board.How to best remove the remaining plaster? Is chipping away at it the only method?

- Use a four inch razor scraper to scrape off the worst of it then use a wet sponge and the rest should wash off easily.Also if you need to you can wet the plaster to help make it easier to scrape.

- Q: Wood fiber cement board | US rock cement board use

- Wood fiber cement board is a kind of natural wood and natural cement, the use of high-pressure slurry technology integrated sheet. With excellent characteristics of wood and cement.

- Q: Home decoration ceiling with what plate is it?

- The so-called ceiling, also known as the ceiling or ceiling, is an important building decoration works. Ceiling is not only beautiful, but also very practical, with insulation, heat insulation, sound insulation, the role of sound absorption. Then we have to look at the decoration of the ceiling of the material which!

- Q: Want to know the cement fiber board recipe and check your product for compliance

- Cement fiber board is based on siliceous and calcium materials

- Q: Do the ceiling is good or good with gypsum board good

- Generally used gypsum board ceiling, do both beautiful and practical. Ette board, although moisture, but do not beautiful, nor cost-effective.

- Q: FC fiber cement plate can be affixed to the aluminum plate?

- Our kitchen and toilet partition ah, closet ah, the ceiling ah, the floor, ah and many other aspects can be used fiber cement board, so now as long as there is a building where you can use fiber cement pressure plate, and fiber cement board is now in the market On the night market uneven, only the choice of high-density fiber cement board is the most reliable, most competitive materials.

Send your message to us

Two Sides Sanding Fiber Cement Board

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords