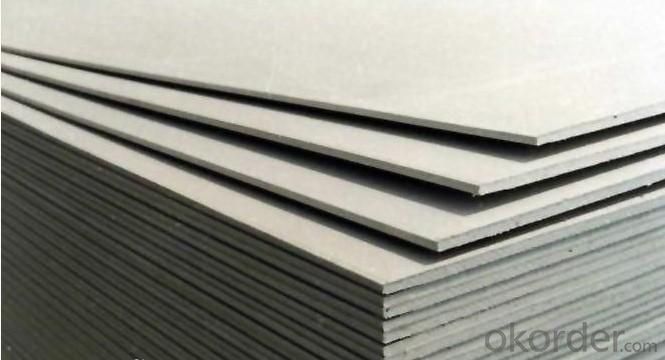

Fiber Cement Board 6mm Fiber Cement Board 6mm

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 3000 pc

- Supply Capability:

- 10000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

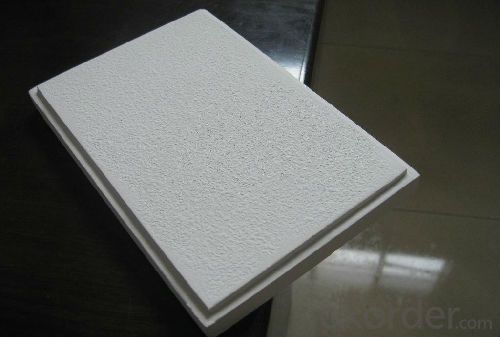

The tile is made by high-density fiberglass with compound decoration wool

on the surface and fiberglass wool on the back .The edges are painted. With the

characteristics of square in edges and angle,it will be parallel to suspension system after installation.

Product Applications:

The titles are manufactured from high density dry felf resin bonded fiberglass wool, with fine texture painted glass tissue facer,plain tissue backer and sealed and painted edges.square edge titles will be paralled to suspension system after installation.

Product Advantages:

1)Incombustibility/Non-flammability: Consmos Calcium silicate board is non-flammable and conforms to the national grade A standard (GB8624 Grade A) with excellent fire resistance property. In case of fire, the board will not burn and not give off toxic smoke.

(2)Thermal/heat insulation: Owing to low heat conductivity, the product has good performances on keeping warm and heat insulation.

(3)Water-proofing and moistureproof: The product is allowed to long-term exposure to moist environment but still very stable. The board still keeps intact after being soaked in water for one month, the phenomenon of swelling and out of shape will not happen. It has good adjusting mechanics like woods. Even it is used on wash house.

(4)Endurance/durability: Consmos Calcium silicate board provides good insulation against bugs, fungus and corrosion. It can last for a long time and will not corrode.

(5)Noise-proofing: Consmos Calcium silicate board provides good insulation against noise.

(6)High-Strength and Light weight: The board is light weight, in this case, it can decrease weight of building greatly. At the same time, the material is high-stength and not easy to be damaged.

(7)Easiness to installation: The construction process does not require complicated tools but just the ones used in regular wood construction. Our board can be fixed on light steel frame with self-attachable screws or a glue gun to nail the bolts into the wooden frame.

(8)Environmental protection: Consmos Calcium silicate board is 100% free of asbestos fiber and will not cause any harm to human body or the environment.

Main Product Features:

Material: Torrefaction Compounded high density fiberglass wool

Face: Special painting laminated with decorative fiberglass tissue

Color: white, black and others to order

Fire-resistant: class A, non combustible

NRC: 0.9-1.0, excellent sound absorption

Thermal-resistant: >0.4 (m2k/w)

Humidity: Dimensionally stable with RH up to 95% at 40c, no sagging, wrapping, or delaminating

Moisture rete:<1% (JC/T670-2005)

Enviromental impact: Tiles and packing are fully recyclable

Product Specifications:

FAQ:

1)Q:Are you a factory or trading company?

A: We are a factory.

2)Q: I am interested in the products but I do not have experience

A: Tell us your budget and target market and we will give you professional advice of exact kinds and quantity.

3)Q: How can I get some samples?

A: We are honored to offer you samples.

4)Q:How does your factory do regarding quality control?

A: Quality is priority, we always attach great importance to quality controlling from every worker to

the very end.

Images:

- Q: Then I have to install marble in replace of this tile. I have laid a lot of ceramic tile but I being told that marble is a real pain in the but. I just started my business and this will be my first big job. Please give me your input. I live in Denver Colorado. Thank you

- Mexichik covered it for the most part, I'd like to add a few things though. If its a light colored tile, back butter the tile too. The trowel marks can show through if you don't. Also, you should seal the tile before you grout at least, but Its recommended to seal it before even installing it. It is a pain but thats why you get more money for installing stone. And be VERY careful, marble scratches so easy.

- Q: over the bath tub is durock cement board enough by itself,or it has to be something else under durock...?

- If the tub wall is on an outside wall it should be insulated & then sealed with plastic, then durock, then the tile. For sound purposes you can insulate the other walls also.

- Q: We have an older house (1957) that has 1 thick beams as a substrate floor. Currently, there is 1/2 plywood on top of the substrate floor. We are going to rip this up so that we can apply mortar to the substrate for leveling purposes. We would put the porcelain tile directly on top of the cement board.The guy at Home Depot (a former contractor) said we can just use 1/2 cement board directly on top of the substrate floor without a layer of plywood underneath. The substrate is old, but sturdy real-wood diagonal beams that lay on top of the joists. He said they are plenty strong and we don't really need to add a plywood subfloor if we use 1/2 thick cement board.What do you think? Do you think we could get away will laying down cement board on top of the substrate floor without plywood for added strength?Thanks!

- To meet the structural requirements for a sub-floor, you will probably need 3/4 T&G plywood or OSB. Chip-Board is a non-structural material meant for shelves and cheap cabinets, and is not water resistant at all. I am not aware of any concrete sub-floor products currently on the market (some are being developed for commercial & multifamily construction - as a means of fire resistance -but I don't think they are available at this time). The current offerings by James Hardy & Sons, Durock (USG) and Wonder-Board are not sub-floors, they are underlayment materials, and should be treated as such. (Install & use them only as the Manufacturer's Installation Instructions indicate.) I prefer the USG product, but that's only my opinion; using any one of these products as an underlayment is far superior to plywood - NEVER use Luan plywood as a ceramic tile underlayment, it is not suited for wet or damp locations and does not bond well with the thin-set cement. The best bet is a quality installation of the plumbing (especially the tub or shower base) and then good maintenance (like caulking, keeping tile and floor grout in good repair. etc.). I suggest any of the cement-board underlayments available, just be sure you ask for the Manufacturer's WRITTEN instructions wherever you purchase the product, then follow them exactly. **************************************..... DO NOT use treated plywood without consulting the manufacturer of the treatment chemical used on the product; most are pretty toxic and need to have contact with outside air until all out-gassing of the chemical has stopped.

- Q: How to solve the old concrete and the new pouring between the concrete does not leak it?

- If the walls can be opened on both sides of the wall, it is recommended to use I-beam or angle steel as a new pouring concrete slab support beam, in the I-beam or angle above a layer of fiber cement board as a permanent template, and then pouring concrete.

- Q: A clerk told there there is a special hole saw for ceeeeeement board--but I never saw the same clerk again. I need to make five 2'' holes.

- You should use a carbide abrasive hole saw for any cement board. Trying to use a standard bi-metal hole saw will only work once, maybe twice. As a plumber, I have to drill through cement board all the time. IMO it's worth it to go to Lowes or Depot to get the right hole saw for the job.

- Q: the post box had 2 -2x6 boards somehow attached to the cement. The boards rotted out and fell over in a windstorm. I'd like to attach a 4x4 post bracket on the cement, then put a pressure treated 4x4 post for the mailbox. I think I need to get the bracket fixed so it's level before I drill into the cement. would I use an epoxy glue to do this?

- You would have to install some pretty sturdy anchors to hold the new post / box in place and expect it to stay put. I (myself) would dig it up and start over, being as I wouldn't like to have a a concrete hunk there all by itself. Or, move over a little and dig another hole, set your new post to the desired elevation, and sakrete the new post.

- Q: Can the Etch board be used for the bathroom?

- It is best not to use, Ed board in a damp place for a long time easy to mold, interface cracking, yellowing. I suggest you use a single brick wall, strong and durable. If you feel more blunt, you can use glass brick wall. Fixed waterproof material for the bathroom is a wise choice, if you think your bathroom waterproof very good, or no steam and the like, then you just used. (Oh you want the wall and then thinner, you can use moisture-proof wood or antiseptic wood to do, but the general use of the plate)

- Q: What is the cement pressure plate?

- Also known as fiber cement pressure plate or cement fiber pressure plate, is a natural fiber and cement as raw material, by the pulp, forming, cutting, pressing, conservation made of a new type of building plate. It is based on siliceous and calcareous materials as the main substrate, with cellulose fiber reinforced materials, mixed with other auxiliary materials, through the copy forming, high pressure curing the formation of a new type of building materials. Is a new generation of "green" building materials, in the excellent moisture, fire performance based on the unique environmental protection features.

- Q: This board is sometimes refered to as tile board.

- Rip out everything to the studs. Put up tile BACKER board. (Durock)

- Q: This is a 1950s sink.

- I assume that you mean the tiles are attached to the counter-top. The process is called demolition, and it can get dusty. Safety glasses are a must, a dust mask is recommended. First, starting at the back-splash, slice any caulk at the seams where the tile joins the wall with a sharp knife. Then, crack the tiles, enough to get a pry-bar under them. Peel, pry or knock the tiles off, exposing the plywood or cement board underneath. If you can find screws or nails attaching the back-splash to the wall, remove them. Then, look underneath the counter for screw or nails which attach the cabinet to the wall, remove them. At this point, you can try prying the whole structure away from the wall(s). Be careful about pry-bar placement. You should only pry where there is a stud on the inside of the wall, typically every 16. If it doesn't budge, look for any fasteners you missed. NB- Before you start, turn off the water, disconnect all the plumbing, cover the drain pipe (to keep debris out of it and sewer gas inside it. A drop-cloth would help in the cleanup. expect to spend some time patching the wall when you're done. Good Luck

Send your message to us

Fiber Cement Board 6mm Fiber Cement Board 6mm

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 3000 pc

- Supply Capability:

- 10000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords