Sanding Fiber Cement Board

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

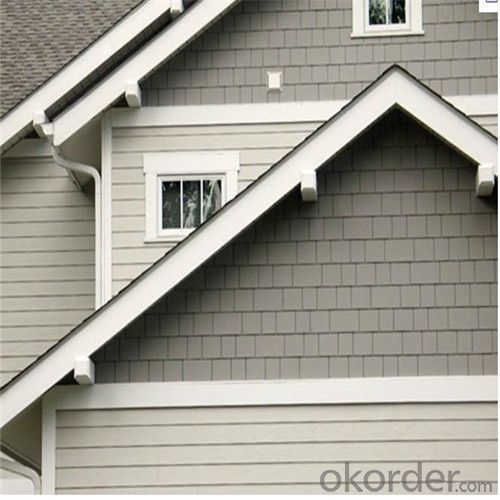

Products Introduction:

Sanle fiber cement board is made of high-grade cement and modified material, reinforced by natural fiber. Being processed by high pressure and high temperature advanced technologies, Sanle fiber cement board is a new building material with excellent performances.

Features

Fire Proof & Insulation

Class A non-inflammability, no toxic gas, low in perveance, good electric insulation material

Waterproof and Moisture Proof

In semi-outdoor area and under high temperature condition, performance of Sanle boards is stable and will not bend or deform.

Thermal Insulation and Sound Insulation

Low thermal conductivity, good heat insulation, high in density, sound proof

Light weight & High strength

Pressured by 5000-ton hydraulic machine, it is high in strength and light in weight. It is not easy to deform and bend, and good for flooring and roofing.

Easy installation

The installation of boards is dry operation, which is faster. It can be processed with ordinary wood working tool. The board is easy to be processed.

Economical and Good looking

The boards are light in weight. Together with the use of keels, they can save cost of construction and decoration. The painting is uniform, and the surface is smooth, making the exterior of buildings good-looking and attractive.

Safe and Harmless

Test result of Sanle boards is better than national radiation protection standards of building materials. The radiation from Sanle boards is equal to that from the lawn 20 meters away from the building. The lifespan of Sanle boards is very long, and they are resistant to acid and alkali, moisture and insects. The toughness and strength remains the same when time passes by. So they can be used for a long time.

Easy to install and easy to replace

Sanle boards can be drilled, cut, engraved, nailed, painted and covered by tiles or sticker when necessary..

- Q: Cement board spray really stone paint

- It is recommended to use the steel structure to do the foundation, first by 4.5 meters high 5 meters wide welded into the door type, and then use the GRC production of cement board (which vertical laying 6 PCT or 8 PCT steel, solder joints) welded to the steel structure, the surface Treatment is waterproof putty and spray really stone paint!

- Q: Can cutting the steel cutting machine cut the cement board?

- Cutting machine: With the development of modern mechanical processing industry, the quality of cutting, precision requirements continue to improve, to improve production efficiency and reduce production costs, with high intelligent automatic cutting function requirements are also improved. The development of CNC cutting machine must meet the requirements of the development of modern mechanical processing industry. Cutting machine is divided into flame cutting machine, plasma cutting machine, laser cutting machine, water cutting and so on. Laser cutting machine for the fastest efficiency, the highest cutting accuracy, cutting thickness is generally small. Plasma cutting machine cutting speed is also very fast, cutting a certain degree of slope. Flame cutting machine for the thickness of the carbon steel material.

- Q: I would like to build 4 steps on a incline. It is above a retaining wall but will be a good foot away from the wall all on firm packed dirt. I have a couple questions. One side of the steps would be next to the garage wall.1. Can I pour cement up against the cinder wall?2. If so how would someone build steps form without any boards against the one side. So basically just have the one side and front plate.3. Or would you recommend having a board against the wall. Or pull it out after the form has set?

- Have you considered buying pre-cast concrete steps?

- Q: i would also like to know what products might help me. Thanks :) Oh, and the type of board i got is called hardi-bord... i didnt know if that might help.

- Hardi-backer okorder is excellent - tile professionals!

- Q: What is the kind of plate?

- Light weight: the use of the United States rock cement board for the wall, the weight of only the same thickness of the brick wall 1/15, block the wall of the 1/10, is conducive to structural seismic, and can effectively reduce the basic and structural cost.

- Q: Composite foam cement board fire board grade and fire resistance limit?

- Should belong to the A1 level, the fire limit according to the thickness will be different, should be in an hour or so.

- Q: how to make cement backer board for bathroom wall tiling?

- the stuff is so cheap compared to how much work you`ll have trying to make it yourself . price lowes and home depot . either one will beat the other one by ten percent .... use the right product and your job will come out showing that you put forth the effort

- Q: Home improvement wall is made of light steel keel + gypsum board, light steel keel + cement pressure plate is good or red brick light weight brick good?

- With light steel keel + sound-absorbing cotton, gypsum board partition This is the best light steel keel can open the secret of some kick is kicked into the exaggerated words do not believe

- Q: How does the cement pressure plate make a large brick? Specific steps and methods?

- Single 9mm cement board must be a keel fixed, and you are 5.8 flat partition, the cement board should be used to engage in three pieces, the keel span is best not more than 45CM, to ensure the number of screws to ensure that the unit area of the hanging Lose power. Cement board tiles above is no problem, just like ordinary cement wiping the same wall construction.

- Q: Our (rented) townhouse has a very bleak cement block basement. Right now the blocks are painted white and cream (and not in a pretty pattern) and the floor is painted dark gray. We want to use the basement as a fitness room and a crafting area for scrapbooking. The lighting is also terrible. What are some ways we can brighten up the space and make it more hospitable without doing any permanent construction (remember we are renting) or spending a lot of money?

- Craig's List will have inexpensive items (albeit used) for decorating. As for light construction work: The most important issue is waterproofing. Use Super ThoroCoat to seal and color the walls. For the floor, use oops paint from home depot. A 5 gallon bucket of an off color should do the trick, and it is normally marked down from $125 to $15. Yes, that is $110 off the normal price. Our local store ALWAYS has one or two garage or concrete floor 5 gallon buckets in the oops area that someone didn't pick up or didn't particularly like the color of. (Remember the most important rules in painting a concrete floor: Clean the floor first, make sure it is dry, apply paint and WAIT 48 hours before walking on it and three more days before putting furniture down on it.) Then, area rugs are cheap enough on Craig's list as well as Ikea furniture. They are BOTH available in good condition on Craig's list with little time wasted looking and great prices. Your landlord will appreciate your use of ThoroCoat or ThoroSeal on the walls and concrete paint on the floor. You will have done the right thing and have made it moisture resistant and waterproof too. FYI, our townhouse basement is done with these sealants. It worked well at keeping dust sealed in as well as taking away the dampness associated with normal basements.

Send your message to us

Sanding Fiber Cement Board

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords