Exterior Wall Decorative Fiber Cement Board construction

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 10000 m²

- Supply Capability:

- 300000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

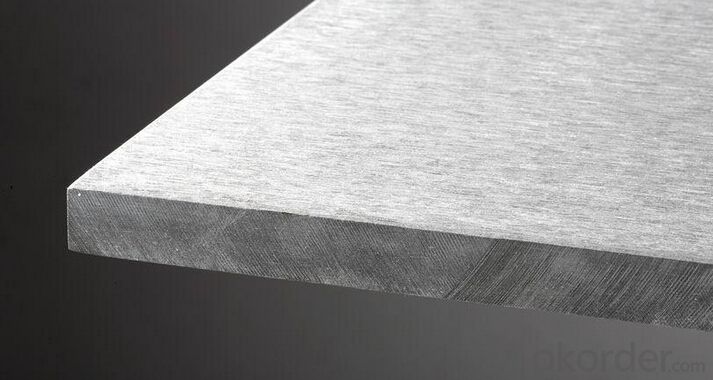

Fiber cement board, using high quality fiber and mineral substances as main content,was made with forming by advanced technique & technological process & through high temperature & high pressure maintenance & special treatment.

Product Applications:

1.Indoor ceiling of industrial and resident building.

2.Partition of industrial and resident building.

3.The ceiling and partition of the bathroom and other wet condition building.

4.Indoor ceiling and partition as base board of the decoration for operation room,clean room of hospital or laboratory .

5.The fireproof board of the air passage.

6.Furniture or furniture's accessories.

Product Advantages:

1)excellent fire-proof

2)excellent damp-proof

3)Durability and long service life

4)high strength

5)stable dimensions

6)good heat and sound insulation

7)non-asbestos

Main Product Features:

1) Elegance and excellent decoration

2) Easy installation and convenient maintenance

3) Best Surface processed with PVC Lamination

4) Heat insulation, thermal insulation, moisture proof, mould proof, sound absorption and noise reduction

5) Incombustibility / Fireproof

6) No dust / no pollution

7) Stucturally strong

8) Over 15 years no transmutation

Product Specifications:

FAQ:

1. Q:What is the different and most important point from other supplier?

A:We guarantee No asbestos if it has asbestos density will be more than 1.4g/cm3 what's more

3.2mm*3000*1220mm can be produced by us other suppliers can not do this size

2. Q:What are the advantages of your board?

A: outstanding light weight ,heat insulation, waterproof, fireproof, sound insulation, fast construction.

3. Q: Is the board fire resistant?

A: Yes, fire resistant 4 h , in the heat of 1000℃.actually it is noncombustible Class A1.

4. Q: Do you have any certificate to help us get government's approval?

A:China testing report and our laboratory' s testing by ourselves as your supporting document.

Because building standards are different in different countries, most of our customers buy the boards for testing and get approval by themselves.

5. Q: If we need samples for customer approval, will it be possible?

A: Of course we can.

6. Q:How to guarantee the quality?

A:Laboratory, integral testing process from raw materials to finished product until loading containers will be done by our factory.

Images:

- Q: The tile guy that I am using has never worked with stone, so I am worried. Can you please give me some insight on some things I should know about using stone (slate) for wall tile in a shower/bath.

- I have to ask is the Slate Milled, or like field stone. 1/2 inch concrete backer board on studs is sufficient. I'd also use a vapor barrier, perhaps even double wall backer board. Vertical installs shouldn't be attempted by someone unfamiliar with the tile species, but I have to assume theyd' like to learn, at least. As an installer he should know the properties of various mortars and mastics used for many species of wall tile, and perhaps apply those to slate, unless it isn't milled. Then it would be more like building a stone facade on a structure. Certainly slate would be more porous, since it's likely unglazed, but glazing it yourself will probably turn into a life long career in maintaining. If this happens to be SLATE in the form of tile, install and grouting will be much easier. If this is to be a more rustic effect, with mosaic shapes in some rough slate, I'd make sure the installer had some better level of knowledge. Steven Wolf Just my 2 sense

- Q: in my new bath/shower i'm using hardibacker cement board. what should i use for the rest of the bathroom walls

- depends on how much you want to spend and what your style is, you could glue on a new fiberglass surround, comes in pieces and just needs to be glued to the board OR tile the area, a lot of work, a lot more expense, but beautiful....

- Q: can i put ceramic tile on laun board in kitchen and will it stick ok?

- It ll stick for awhile but won t last. The total substrate thickness won t support tile. There will be to much deflection and the bond between the tile and luan will come loose from movement. You need a minimum of 1 1/4 total flooring to support tile. Most cases this is 3/4 sub floor and a 1/2 of a cement board or special plywood , properly installed. This come from both the TCA and ATC tile guide hand books. Any questions you can e mail me through my avatar and check my qualifications there. GL

- Q: Installation technology and process of external wall cement board

- Stir: the amount of warm water added to the mixer, wet stirring for 2 minutes; the amount of the blowing agent added to the mixer stirring 8-15 seconds;

- Q: This would be around the bathtub area. Not sure whether to use the same cement board tape and mortar at the ceiling line or to switch to regular wallboard joint compound. Which is correct? Thanks!

- i think most of the time the boards come in a dimension that puts them below the ceiling line and the difference is filled in with water resistant drywall and finished regularly, then most of the cement board is covered in tile so little finish work is needed on it .. if its all the way up probably just tape it and finish as normal but strictly speaking, the whole layout isnt correct if it terminates at the ceiling joint ..

- Q: or add visquine on top of the plywood and then put on the backer board

- no. unless the floor is very uneven

- Q: What are the standards for residential steel structures?

- Steel structure residential system is composed of the envelope structure and steel support structure of the common residential system, is the province of energy-saving new residential system. It is the steel structure of the house to abandon the solid clay brick, the effective use of land resources. Steel residential buildings have advantages in terms of functional, design, construction and integrated economy compared to traditional homes

- Q: Wood keel cement pressure plate partition wall tiles

- It is necessary to remove this partition, many examples have proved that the bathroom partition (including the pipeline) once the use of wood keel, cement pressure plate to do there is a great hidden danger, 1-2 years later, due to the deformation of the wood keel, Of the deformation, attached to any of the above tile material stretch ratio is much smaller than the wood keel material, therefore, must crack or even fall off.

- Q: This is a 1950s sink.

- sure its superb to get rid of each thing however the cement board is 3/8 to a million/2 in. thick and the tile being placed on it truly is a pair of a million/4 to 3/8 counting on the quantity of thin set used. are you able to place a threshold down on the doorway to house for this distinction in top? And if the timber below the tile floor isn't a minimum of a million in. thick then the flexing of the floor will continually reason cracking of the grout lines if no longer the tiles them self. those are a pair issues people forget whilst wanting a tile floor. good success

- Q: i live in a country where houses are made with bricks..but i made my house just like in USA , but there is one only problem i need cement board to finish the bathroom , since we don't have cement board here for sale , and i can't afford import from USA , i was wondering that i can make it , i'm sure that i can make it , but i just need to know how to prepare de cement i would be appreciated if anyone help me thanks

- Back in the old days(I'm an old man) they used lathe and plaster. They also used lathe and cement. Lathe and plaster with a cement coating.

Send your message to us

Exterior Wall Decorative Fiber Cement Board construction

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 10000 m²

- Supply Capability:

- 300000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords