Non Asbesto Fiber Cement Board

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Products Introduction:

Sanle fiber cement board is made of high-grade cement and modified material, reinforced by natural fiber. Being processed by high pressure and high temperature advanced technologies, Sanle fiber cement board is a new building material with excellent performances.

Features

Fire Proof & Insulation

Class A non-inflammability, no toxic gas, low in perveance, good electric insulation material

Waterproof and Moisture Proof

In semi-outdoor area and under high temperature condition, performance of Sanle boards is stable and will not bend or deform.

Thermal Insulation and Sound Insulation

Low thermal conductivity, good heat insulation, high in density, sound proof

Light weight & High strength

Pressured by 5000-ton hydraulic machine, it is high in strength and light in weight. It is not easy to deform and bend, and good for flooring and roofing.

Easy installation

The installation of boards is dry operation, which is faster. It can be processed with ordinary wood working tool. The board is easy to be processed.

Economical and Good looking

The boards are light in weight. Together with the use of keels, they can save cost of construction and decoration. The painting is uniform, and the surface is smooth, making the exterior of buildings good-looking and attractive.

Safe and Harmless

Test result of Sanle boards is better than national radiation protection standards of building materials. The radiation from Sanle boards is equal to that from the lawn 20 meters away from the building. The lifespan of Sanle boards is very long, and they are resistant to acid and alkali, moisture and insects. The toughness and strength remains the same when time passes by. So they can be used for a long time.

Easy to install and easy to replace

Sanle boards can be drilled, cut, engraved, nailed, painted and covered by tiles or sticker when necessary..

Product parameters

Item | Unit | Requirement | ||||

Medium density | High density | |||||

Density | g/cm3 | 1.2<D≤1.5 | 1.5<D≤2.0 | |||

Water absorption | % | ≤30 | ≤25 | |||

Non-combustibility | GB 8624-2006, grade A | |||||

wet expansion | % | ≤0.25 | ||||

Beding strength | dry | MPA | Strength grade class III | 20 | Strength grade class IV | 24 |

Saturation with water | 12 | 14 | ||||

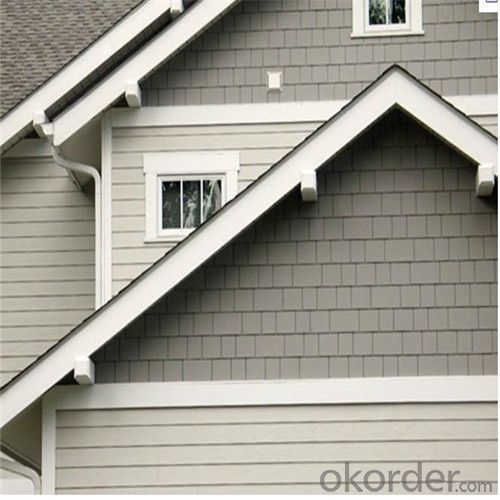

Applications

Exterior side boards, indoor partition walls, sound-proof ceiling, decoration boards, complex walls, outdoor billboards, division boards and floor boards

- Q: in my new bath/shower i'm using hardibacker cement board. what should i use for the rest of the bathroom walls

- depends on how much you want to spend and what your style is, you could glue on a new fiberglass surround, comes in pieces and just needs to be glued to the board OR tile the area, a lot of work, a lot more expense, but beautiful....

- Q: Then I have to install marble in replace of this tile. I have laid a lot of ceramic tile but I being told that marble is a real pain in the but. I just started my business and this will be my first big job. Please give me your input. I live in Denver Colorado. Thank you

- Mexichik covered it for the most part, I'd like to add a few things though. If its a light colored tile, back butter the tile too. The trowel marks can show through if you don't. Also, you should seal the tile before you grout at least, but Its recommended to seal it before even installing it. It is a pain but thats why you get more money for installing stone. And be VERY careful, marble scratches so easy.

- Q: how to install cement backer board behind a bath tub?

- operation is same as dry wall

- Q: Do you need to finish a cement board for a shower like you would if it were drywall?

- Or since you already are going to have thin-set.... Use mesh tape and mud the tape in with thin-set....same thing.... works just as well. The primary reason for taping and mudding the joints is keeping moisture OUT its not a leveling out or cosmetic issue like drywall, make it flush and cover the tape with material and your ready to tile. DO NOT USE reg drywall mud it is not for wet applications.....

- Q: I have a walk in closet with plywood pieces for a floor. Don't I need cement board installed before putting in wood flooring? Thanks for your help!!

- You dont need cement board . You would just install it over the plywood subfloor. Personally I would go down to Home Depot or similar store and look at their floring and talk to a salespersomn there. If you have not done this before you need to find professional help.

- Q: Or only where the ceramic tile floor will be installed. Should the pan just sit on the 5/8 wood subfloor?

- Won't hurt to put the durock down. Are you using a rubber drip pan, or steel? I like the rubber, much more versatile. I also like to put cement down, and set the base in while the cement is wet. This gives yo a good base, the fiberglass can't move and deteriorate.

- Q: Thanks Alex. How much you think I should charge to install each 4x8 sheet of cement board?

- I used to charge 2.50$ a s/f to install board or prep an area. That would include the board , thin set and nails ( or screws)to do it properly. 4x8 cement board is hard to find and heavier the all HE!!, so hire a friend. 3x5 sheets are much easier to handle by yourself. Any questions you can e mail me through my avatar. GL

- Q: Bought new ceramic tile for kitchen and the old stuff is hard to get up. I want to keep the cement board that is in there for the new stuff.

- Putting down backer board is a waste of time and money when going over a smooth cement floor. Backer board is used to stiffen up an existing wooden floor or wall. It can also be used when planning a shower to allow for build up to slope to a drain. As far as sweating is concerned backer board will not prevent it if it is a problem. It will just make your floor thicker. The sweat comes from the air contact with a cooler floor surface it is not from water seeping through the floor. A dehumidifier will help to solve this problem in the summer months. Make sure you use a sufficient base of thinset (1/4 inch trowel minimum, 1/2 inch if uneven or rough spots). Mixing a latex additive to the grout is also a good idea in below grade and outdoor grouting situations.

- Q: i can ollie on a rug ok but then on the cement my board moves and the back wheels dont get up i know i am doing the ollie right but when i try it on the cement the board moves and the back wheels dont go up i really need help because most of my friends skate and they are really good and i would like to start skating but i dont know if i am good please give me some tips about ollieing on the cement thanks!

- Your pushing your board back with your feet. Try not to do this and practice. The only way to be good in skateboarding is practicing everything hard.

- Q: i notice that the white cement is not sticking properly to my ceiling..anyone could advise me on this.. is it due to the surface of the ceiling or i did not blend it properly????

- try using plaster works better...

Send your message to us

Non Asbesto Fiber Cement Board

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords