fiber cement board

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- 120000pcs pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1,LUTAI Fiber cement board is a stable performance and light weight building &decoration board used cement as major and natural reinforced, with the process of pulping,emulsion,forming,pressurization,autoclaving,

drying and surface treatment.

Thickness : 4.5mm-30mm

Size :1200*2400mm, 1220*2440mm, any size that u need .

Surface : 40#-120# sanding surface , polished surface , tapered edge .

2,Product characteristics :

Density : 1.2-1.5G/CM3

Fire-proof Rate : A-Class incombustible (GB8624-1997)

Incombustibility(min): 240 minutes (GB/T9978-1999)

Water content : ≤30% Swelling ratio: ≤0.4%

Anti-bending Strength: ≥16MPA Frost resistance : Don’t appear cracking and delamination after 25 cycles of freezing and thawing . (GB/T7019-1997)

Radioactivity: standard of GB6566-2001 (A-class Decoration Materials)3,Recommed application:

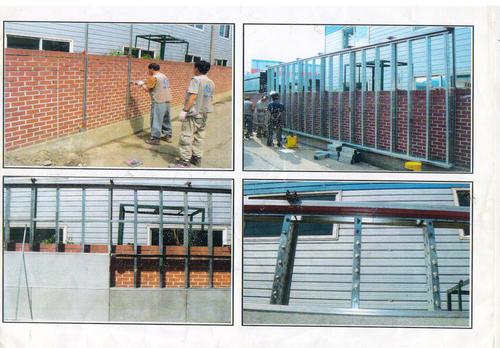

Partition board , exterior wall cladding , panel, suspended ceilings ,lightweight grouting panel, interior dry wall decoration board ,interior wall after painting and coating .

- Q: Cement board spray really stone paint

- In fact, you can do the first door with wood or asbestos fastener to do the foundation ah, and finally do paint, the same effect.

- Q: Can the board be replaced by woodworking board?

- Ethe board (fiber cement board) is a high strength, durability and other superior performance of the fiber silicate sheet, with a variety of thickness and density, 100% does not contain asbestos and other harmful substances. For non-combustible A1 grade products. With fire, moisture, waterproof, sound insulation effect, environmental protection, installation fast, long life and other advantages. Commonly used as a bathroom partition, outdoor roof roof, external wall insulation board, interior decoration, smallpox, etc .; can also replace the use of gypsum board in the decoration used as a substrate. The outer surface of the tile and stone can be, but to paste. But some places can not replace the woodworking board, such as: the wall to bear the load, etc., another grip nail force is not OK. Mainly used instead of gypsum board, because it is more waterproof, moisture.

- Q: Wooden cement board and cement pressure plate is the same thing?

- Wooden board is a new environmentally friendly decorative plate, which is composed of 70 percent of Portland cement and 20 percent of mineralized wood, as a decorative panel interpretation of a clean water style, simple construction , Easy and easy. The basic construction method is as follows; Available general wood saws or saws, tungsten carbide saw blade cutting. * Can be used HSS drill drill drill to get the best results. The following are the same as the " * It is recommended to use the general woodworking 60 to 80 sandpaper whole mill. The following are the same as the " * Screw holes and nail holes can be filled with the general filler to fill the wood chips after cutting the wood chips. The following are the same as the " * Available wooden frame, galvanized skeleton as the architecture. The following are the same as the " * Screw the application of the self-tapping screws. The following are the same as the " * Nail 10mm thickness below the need for drilling can be nailed. 12mm above the need to drill a size of nail diameter of 80% of the positioning hole. * When the rivet is used on the galvanized frame, the margin (A) is twice. Indoor construction plate joints need to stay 3-5mm of the joints * joints can be used strip foam and silicon was Kang blockage. The following are the same as the " Surface treatment is recommended to use transparent paint can be modified to highlight the wood surface of a unique high-quality texture of the cement board lines.

- Q: I am laying a new tile floor over plywood subfloor. I have Durock cement backerboard. The area I'm covering is only 4'3 x 6'8. I don't really want to put the money out for power saws ($60+) so I am planning to use a hand saw. What kind is most appropriate? Can I use a small utility knife for the smaller details?

- I think most guys just use a utility knife (with a sharp blade) to score the board and snap it kind of like drywall. You'll use a few blades but I think it'd work fine. Use the fasteners recommended by the manufacturer. I see a lot of roofing nails being used but I don't think they're the best thing to use. The Durock wasn't cheap and neither is the tile you'll be installing. Don't try to save fifty cents on fasteners.

- Q: Application of cement pressure plate

- Use of places such as commercial buildings, entertainment venues, factories, warehouses and other industrial construction areas, new residential, renovation and renovation of residential construction areas, hospitals, theaters, stations and other public places

- Q: Why plastic materials use glass fiber reinforced

- Its plastic is relatively brittle, in order to fall resistance, compression, increase strength and toughness. It is a reason to add steel to the inside of the cement board. Notebook shells usually add fiber.

- Q: Hi everybody! I just installed hardibacker boards in my bathroom. But I had to remove 1 pc 'coz I made a mistake. Can I still use it again? I screwed it every 8 inches around the edges and along every stud. Can I just cover the holes with thinset? Thanks!

- Yes --- Will look great from my house

- Q: is there a spray on cement moisture barrier to use under laminate flooring?

- can find at any home improvement store or concrete supplier try to get a latex version so it doesn't interfere with the laminate adhesive if you are doing that type another product is called drylok you can roll it on and the concrete is now basically waterproof

- Q: Cement fiberboard dry hanging practice?

- Fiber cement pressure plate preparation: first with the colorimetric method of fiber cement pressure plate color selection and classification; the whole center of the fiber cement pressure plate color should be consistent, and according to the design size and drawings requirements, dry hanging fiber cement pressure board Aluminum pendant mounted on the back, according to the back of each plate 6 aluminum pendant (the largest sheet cross-sectional size of 2780 × 1220mm). In order to ensure that the aluminum pendant position is accurate and vertical, in front of the fiber cement pressure plate in accordance with the vertical spacing of the vertical keel 600mm and fiber cement pressure plate length equal to the size of the cross cross cable, fixed at the cross point supporting aluminum fasteners, aluminum pendant 10mm long, 4mm thick stainless steel screws fixed on the back of the fiber cement pressure plate, aluminum fastener after installation must be reviewed its level and vertical.

- Q: I currently have a cheap ceramic tile on my bathroom floor. It is set on cement board. I would like to replace it with a slate-like porcelain tile. Can I simply remove the ceramic tile or do I have to also tear out the cement board and replace it? How big of a project is this? I previously installed porcelain tile on a plywood floor over cement board and am wondering if the demolition creates a bigger problem.

- You could lay over what is there if the ceramic isn't slick or shiny on top. Getting off the old may not be as hard as one would think. Then again it may be a bear, I'd smack one with a hammer and just see how hard it would be to get out. This would not create such a height gain in the long run. If it is a nightmare then I'd cement the broken tile you took outs spot and go over top what is there if possible. Getting the old cement board completely out I believe would be a chore but I may be wrong.

Send your message to us

fiber cement board

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- 120000pcs pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords