Durable Fiber Cement Board Exterior Wall Siding

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1,Structure of (Cement Boards) Description

1) fiber cement board

2) Non-pollution: 100% non-asbestos,

3)waterproof, soundproof, insect-proof

2015* durable fiber cement board exterior wall siding

Description

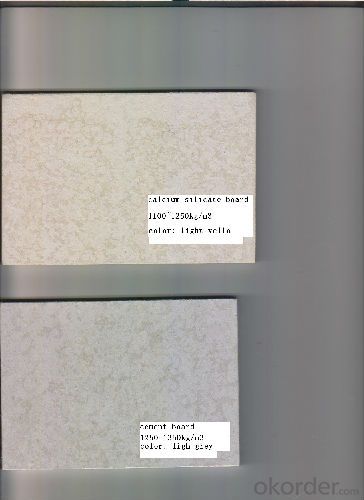

Calcium Silicate Board /fiber cement board

Non-asbestos Calcium Silicate Board----Raw materials are Portland cement, high-purity quartz powder, minerals (mica and perlite etc), and a variety of additives. It is light weight energy-saving building plate with non-asbestos fiber that treated by high-temperature and high-pressure steaming process according to the KTN300 technological standards. It is no asbestos, proved by State Building Material Testing and Inspection Center according to the Standards of Non-asbestos Building Products.

2,Main Features of the (Cement Boards)

Property:

ISO 9001; CQGC; CNAS

waterproof, soundproof, insect-proof

Non-pollution: 100% non-asbestos, no VOC gas, and no radiation.

Fireproof: Incombustibility Grade A; complying with BS 476 Part4\ Part6\ Part7; releasing no toxic gas; zero smoke coefficient.

Economical: Light weight but high strength, save construction costs.

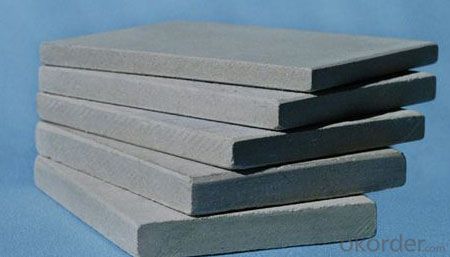

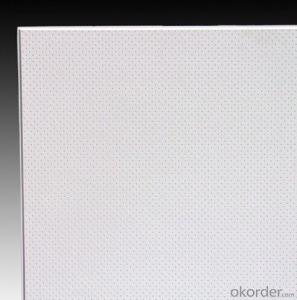

3,(Cement Boards) Images

4,(Cement Boards) Specification

| Standard Data of the Middle Density Firber Cement Board | ||||||||

| Standard Size | 1220X2440mm/1200X2400mm | Max Width | 1250mm | Max Length | 4880mm | |||

| Thickness | 4-30mm | Density | 1.3-1.7g/cm3 | |||||

| Wet Expansion Rate | ≤0.23% | Water Penetration | ≤25% | |||||

| Forst Resistance | No Layer & no cracks after 25 cycles under freezing and thawing | |||||||

| Incombustibility | Incombustible Class A1 | Radioactivity | Decorative materials Class A | |||||

| Flexural Strength | Air dried Condition ≥18 | Water Penetration | Back side without water drop after 24 hours | |||||

| Saturated Condition≥14 | ||||||||

5,FAQ of (Cement Boards)

Application:

Main application: partition wall and ceiling

Fireproof structure: fireproof wall, fireproof door and fireproof furniture.

Heat insulation structure: internal heat insulation layer and heat insulation of outer wall.

Sound insulation structure: cinema, meeting hall, music hall, etc, for example.

Wet areas: basement, toilet, kitchen as well as other environment of low temperature and corrosion.

Backing-up structure: best used as filling plate of screen wall. We have developed supporting system of backing-up plate for renowned units of screen wall construction.

Other purposes: applied to furniture, movable floorboard, and office dividing wall.

Specification:

Density: 1.1-1.25g/cm3

2440×1220×6 -25mm

Non combustibility: Class- A (A1)

- Q: Fiber cement board and glass magnesium board how to distinguish

- Hello, professional answer you, glass magnesium plate is magnesium oxide, magnesium chloride, water ternary system is modified by the configuration, because of its A-class fire, water and moisture, while green, in line with sustainable development characteristics, by the state recommend.

- Q: or add visquine on top of the plywood and then put on the backer board

- That is the proper way to do it. You need the thin set to act as a filler so there are no voids at all between the ply and the cement board. 1/4x1/4 notched trowel is the required trowel. This is according to tile installation ( both ATC and TCA tile guide line codes) and the cement board manufactures way to do it. Any questions you can e mail me through my avatar and check my qualifications there. GL

- Q: how do I lay cement board on a concrete floor with out screws?

- That would be an improper installation. The screws push the board down into the adhesive. Go to the manufactures website. They have guides on how to properly install cement board. I used Durock to build a hearth for my wood stove. Their website actually had an installation document on how to do it.

- Q: i am wondering the durablability difference. Is one more sturdier than the other?

- In a way, fiber cement board is better than stone veneer. Houses are rotting down everywhere stone veneer is installed incorrectly. There's a lot of hacks out there gluing the stuff straight onto wood, making it the next home repair nightmare. If done correctly, it might be more durable but it's not sturdier.

- Q: Cement board in Malaysia?

- you can find cement board sell in most hardware shop in malaysia

- Q: What is the national standard for the thickness and hardness of indoor residential cement?

- The surface of the wall is the cement mortar leveling layer, the general thickness is not required, the mortar cement ratio, cement label, flatness and so on are required. Look at your situation, it should be cement mortar in the proportion of cement is too low, you can find the developer claims, but it is best private or to the local construction commission of the quality inspection station complaints, the court reluctant to accept these small cases, say the time Also can not afford to drag.

- Q: Do you have a living room with a cement board?

- At present, the most used way to ceiling is the aluminum slab ceiling and keel ceiling and so on. With cement board ceiling, one modeling is not easy to do it. The second reason is that the ceiling when the joints are easy to crack, and deal with very troublesome. At present, this way the ceiling has been gradually forgotten by everyone.

- Q: Cement pressure board do wall do not work? Solid and waterproof there is no problem?

- Of course, the cement pressure plate is not the external walls of material, solid and waterproof are not meet the requirements.

- Q: almost finished with tiling on cement board wall. ran into problem with corner applying bull nose piece.?

- Since you don't tell us what your problem is, it's a little difficult to help you. In the future, completely lay out your tile project dry, so you don't run into any surprises.

- Q: Want to do their own cement board, but made out of the color on the white, how can make the cement board color made dark gray

- Powder can be added to the cement carbon black, 1% content. The role of carbon black in cement is as follows: Carbon black is used in many industries, such as ink, rubber and so on. These are more common applications. And I am afraid a lot of people do not know is that carbon black is also used in cement, and the role is more than one. In addition to carbon black can be used as a colorant of cement, but also can be used as cement crushing accelerator.

Send your message to us

Durable Fiber Cement Board Exterior Wall Siding

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords