EPDM Rubber Roofing Waterproof Membrane

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2000 m²

- Supply Capability:

- 300000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

EPDM Waterproof Membrane

Introduction for EPDM Waterproof Membrane

This waterproof coiled material is of high elasticity with best performance among high polymer waterproof coiled material in the world.It is also the most typical one in the world.Waterproof coiled material made of ternary ethylene-propylene rubber of ‘CHEN SHENG’ brand is produced with the use of the most advanced continuous extrusion and vulcanization technology and related equipments which are specially designed for production of such product.It is good in compactness,without bubble and performance difference in length and breadth,performances reach or exceed the demands of GB18173.1-2012 standard.

Characteristics for EPDM Waterproof Membrane

1.Excellent anti-aging performance, service life can reach 50 years;

2.High elongation, high tensile strength, heat treatment size change small;

3.Plant root penetration resistance is good

4.Good low temperature flexibility

5.Application is convenient, overlapping is firm and reliable, no environmental pollution;

6. Resistance to chemical corrosion, can be applied to special places;

7.Maintenance is convenient, the cost is low

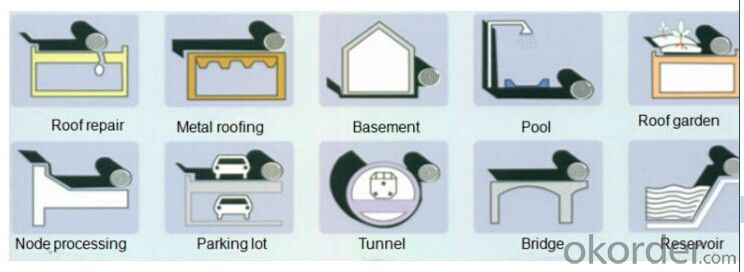

Application for EPDM Waterproof Membrane

1) Roofs, Basement, Toilet

2) Industrial and civil building waterproofing

3) Geo-synthetic liner for swimming pool, channels, irrigation system

4) Especially suit for projects with high requirements in durability, anti-corrosion and deformation

Specification for EPDM Waterproof Membrane

Item | Thick(mm) | Width | Length(m) | Color |

Spe | 1.0—2.0 | 1.2m/2m/3m/4m | 20 | Black |

Deviation | -1 +15 | --1 | Multicolor |

Technical Sheet for EPDM Waterproof Membrane

EPDM Waterproof Membrane ASTM Standard : D-7465 | ||||

Property | Test Method | Units | Mininum ASTM | |

D-7465 | ||||

Sl | Eng | |||

Specific Gravity | ASTM D-792 | gm/cc | 1.1 | 1.1 |

Unit Weight | ASTM D-751 | kg/m2 | 1.3 | 0.27 |

Thickness Type 1 | ASTM D-412 | mm(in) | 1.02 | 0.04 |

Tensile Strength. Die C | ASTM D-412 | Mpa(psi) | 9 | 1305 |

Ultimate Elongation,Die C | ASTM D-412 | % | 300 | 300 |

Tear Resistance,Die C | ASTM D-624 | Kn/m(lbf/in) | 26.27 | 150 |

Puncture Resistance | ASTM D-4833 | N(lbs) | 133 | 30 |

Shore A Durometer | ASTM D-2240 | 65-10 | 65-10 | |

Ozone Resistance | ASTM D-1149 | No Crack | No Crack | |

Multiaxial Elongation | ASTM D-5617 | % | 100 | 100 |

Heat Aging 28 days at 240 degrees | ASTM D-573 | |||

Tensile Strength, Die C | ASTM D-412 | MPa(psi) | 8.3 | 1205 |

Ultimate elongation, Die C | ASTM D-412 | % | 200 | 200 |

Tear Resistance, Die C | ASTM-624 | Kn/m(lbf/in) | 21.9 | 125 |

Accelerated Aging Xenon Arc | ASTM G-155/G-151 | Pass | Pass | |

Brittleness Point | ASTM D-2137 | -45 °C | -49 °C F | |

Water Absorption | ASTM D-471 | % | +8,-2 | +8,-2 |

Water Vapor Permeability, max | ASTM E-96 | Permils | 2.0 | 2.0 |

Linear Dimensional Change,max | ASTM-D-1204 | % | +/-1.0 | +/-1.0 |

Chronic Toxicity Screening | EPA/600/4-89/001 | Method 1000.0 | Pass | Pass |

FAQ:

Can you produce 4m width?

Yes, no problem for us. We have four bases in China, largest one in this field.

How many quantity in one 20'' container for 1.2mm and 1.5mm?

480rolls, 11520m2 for 1.2mm and 400rolls, 9600m2 for 1.5mm

Can you provide free samples?

Yes, our samples are free, but express fees usually on buyer's account.

- Q: Can a waterproofing membrane be used on cinder block surfaces?

- Yes, a waterproofing membrane can be used on cinder block surfaces. Cinder blocks are porous materials that can absorb water, so applying a waterproofing membrane can help prevent moisture from penetrating the surface and causing damage. The membrane acts as a barrier, preventing water from infiltrating the cinder blocks and protecting them from moisture-related issues such as mold, mildew, and deterioration. It is important to properly prepare the cinder block surface before applying the membrane to ensure proper adhesion and effectiveness. Additionally, choosing a waterproofing membrane specifically designed for cinder block surfaces will provide the best results.

- Q: Can a waterproofing membrane be used on parking garages?

- Yes, a waterproofing membrane can be used on parking garages. Waterproofing membranes are commonly used in parking garages to prevent water penetration and protect the structure from moisture damage. They can be applied to the roof, walls, and floors of the garage to create a barrier against water intrusion, helping to extend the lifespan of the parking structure and prevent costly repairs.

- Q: Can a waterproofing membrane be used on precast nickel surfaces?

- Yes, a waterproofing membrane can be used on precast nickel surfaces. Waterproofing membranes are designed to create a barrier against moisture and prevent water penetration. They can be applied to various surfaces, including concrete, metal, and even nickel. However, it is important to ensure that the waterproofing membrane is suitable for use on nickel surfaces and is compatible with the specific type of precast nickel being used. It is recommended to consult with a professional waterproofing contractor or the manufacturer of the membrane for guidance on the specific application and to ensure proper adhesion and effectiveness of the membrane on precast nickel surfaces.

- Q: Can a waterproofing membrane be used for a swimming pool liner?

- Indeed, a waterproofing membrane is suitable for serving as a swimming pool liner. In reality, it is a widely adopted and efficient approach to achieve a watertight seal in swimming pools. Waterproofing membranes are engineered to possess durability and resistance to water infiltration, making them an ideal selection for pool lining. They act as a safeguarding barrier, preventing water from permeating into the ground, which could lead to structural harm and leaks. Furthermore, waterproofing membranes can be tailor-made to fit any pool size and shape, thus ensuring a perfect fit and optimal performance in terms of waterproofing. All in all, opting for a waterproofing membrane as a swimming pool liner is a dependable and cost-efficient resolution to uphold the integrity and longevity of the pool structure.

- Q: Can a waterproofing membrane be used for elevator pits and sump pits?

- Elevator pits and sump pits, commonly prone to water leakage and moisture problems, can benefit from the use of a waterproofing membrane. These membranes are designed to resist water penetration and create a barrier against water intrusion, effectively sealing the pits. Materials such as rubberized asphalt, EPDM, or PVC are typically used to construct these membranes, which are then applied to the walls and floors of the pits. The installation of a waterproofing membrane provides protection to the elevator and sump pits, safeguarding them against water damage, including corrosion, mold growth, and structural deterioration. This not only ensures the functionality and durability of the pits but also creates a safe and healthy environment for occupants and equipment. Nevertheless, it is essential to consider the specific requirements and regulations of elevator and sump pit installations, as different jurisdictions may have their own codes and standards that must be adhered to. Furthermore, proper installation and regular maintenance of the waterproofing membrane are crucial to guarantee its effectiveness in preventing water infiltration.

- Q: Can a waterproofing membrane be used for underground fuel storage tanks?

- Yes, a waterproofing membrane can be used for underground fuel storage tanks. The membrane helps to prevent the infiltration of water into the tank, protecting it from corrosion and potential leaks.

- Q: What are the proper installation techniques for a waterproofing membrane?

- Proper installation techniques for a waterproofing membrane involve thorough surface preparation, ensuring the substrate is clean, dry, and smooth. The membrane should be applied with the correct adhesive or appropriate fasteners, following the manufacturer's instructions. It is crucial to overlap seams and corners correctly, ensuring a watertight seal. Regular inspections and maintenance are also necessary to ensure the longevity and effectiveness of the waterproofing membrane.

- Q: How does a waterproofing membrane handle hydrostatic pressure?

- A waterproofing membrane handles hydrostatic pressure by creating a barrier that prevents water from penetrating through it. It is designed to withstand the pressure exerted by water, ensuring that it remains intact and prevents any leakage or seepage.

- Q: Can waterproofing membranes be used on outdoor decks?

- Yes, waterproofing membranes can be used on outdoor decks. They provide an effective barrier against water and moisture, protecting the deck's structure and preventing damage from weather elements. Waterproofing membranes help to extend the lifespan of the deck and maintain its aesthetic appeal.

- Q: Can waterproofing membranes be applied over existing surfaces?

- Yes, waterproofing membranes can be applied over existing surfaces. In fact, this is a common practice in construction and renovation projects. Waterproofing membranes are designed to provide a protective barrier against water infiltration, and they can be applied over various surfaces such as concrete, wood, metal, or even other waterproofing systems. By applying a waterproofing membrane over an existing surface, it helps to prevent water damage, including leaks, mold growth, and structural deterioration. However, it is important to ensure that the existing surface is properly prepared and cleaned before the membrane application to achieve optimal adhesion and performance. Additionally, it is recommended to consult with a professional waterproofing contractor to determine the most suitable membrane type and installation method for the specific project requirements.

Send your message to us

EPDM Rubber Roofing Waterproof Membrane

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2000 m²

- Supply Capability:

- 300000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords