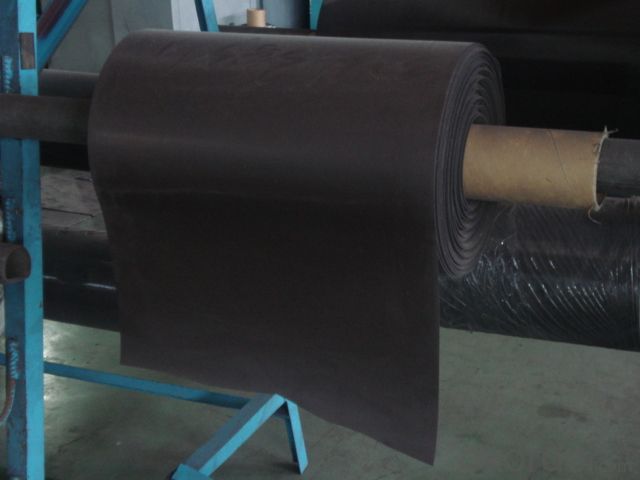

EPDM Rubber Waterproofing Membrane for Roof Protection

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5000 m²

- Supply Capability:

- 100000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Description:

EPDM (OP) Rubber Waterproofing membranes is a synthetic rubber, synthetic tire blends as the base material, adding reinforcing agents, softeners, antioxidants, curing agents processing aids to promote mixing by kneading, mixing, extrusion, rolling and curing, shaping and other processes can be processed into sheet curling volume of new high elastic waterproof material.

Application Range:

Mainly used in all types of Industrial and civil b uildings

roofing , office buildings, supermarkets, steel roofing, basements, tunnels, bridges

and other impermeable, waterproof construction .

Features

1) Excellent weather-ability, durability and size stability

2) Good adaptability to high and low temperature, UV resistant and anti-corrosion

3) High tensile strength and good elongation, accommodating to structure movement

4) Easy installation, solid joint, and no environmental pollution

5) Good rooting penetration resistance

6) Service life up to 50 years

Application

1) Roofs, Basement, Toilet

2) Industrial and civil building waterproofing

3) Geo-synthetic liner for swimming pool, channels, irrigation system

4) Especially suit for projects with high requirements in durability, anti-corrosion and deformation

Introduction for EPDM Waterproofing Membrane:

Tensile Strength N/CM | Normal temperature: 60 ; 60°C: 30 |

Breaking Elongation % | Normal temperature: 400 ; -20°C: 10 |

Tear Resistance N | 20 |

Impermeability, 30 min no leakage | 0.3Mpa |

Low Temperature Bending °C | -20 |

Heating Shrinking mm | Extension: 2 Shrink: 4 |

Heat Resistance (80°C×168h) | Tensile Strength % : 80 ; Keeping rate of adhesive breaking:70 |

Alkali resistance (10% ca (oh)2 solution,normal temperature ×168h)) | Tensile Strength % : 80 ; Keeping rate of adhesive breaking:80 |

Synthetic aging | Tensile Strength % : 80 ; Keeping rate of adhesive breaking:80 |

FAQ of Waterproofing Membrane

a.Can we get some samples before place order?

Answer: We can send the free samples to you by freight collect.

b.How many years can your PVC membrane guarantee?

Answer: We will guarantee the quality for 5 years at least.

c.Which countries you ever export the product?

Answer: We export the PVC membrane to South Africa, Middle east and even European countries.

- Q: Does a waterproofing membrane have any impact on the appearance of a surface?

- Yes, a waterproofing membrane can have an impact on the appearance of a surface. Depending on the type and application method of the membrane, it may add a layer of protection that alters the texture, sheen, or color of the surface. Additionally, some membranes may be visible or create a slightly raised or textured effect on the surface. However, there are also transparent or thin membranes available that have minimal impact on the appearance of the surface.

- Q: Can a waterproofing membrane be used for theaters or concert halls?

- Theaters and concert halls can benefit greatly from the use of waterproofing membranes. These membranes are commonly employed in construction projects to safeguard buildings against water damage by preventing water infiltration. They are applied to various surfaces, including walls, floors, and roofs, creating a barrier that stops water from seeping through. In the case of theaters and concert halls, where the protection of the building structure and equipment is of utmost importance, waterproofing membranes can be extremely advantageous. They play a crucial role in preventing water damage to delicate equipment like audiovisual systems, lighting fixtures, and musical instruments. Furthermore, these membranes ensure a dry and comfortable environment for both performers and audience members by preventing water leakage and moisture buildup. In conclusion, the use of a waterproofing membrane in theaters or concert halls guarantees the longevity and functionality of the building, creating a safe and enjoyable experience for all involved.

- Q: Can a waterproofing membrane be used on metal block surfaces?

- Metal block surfaces can indeed benefit from the use of a waterproofing membrane. These membranes are specifically designed to form a barrier against water and moisture, and they are versatile enough to be applied to various types of surfaces, including metal. By adhering to the metal surface, the membrane creates a protective layer that not only prevents water infiltration but also safeguards the metal against rust and corrosion. However, it is crucial to guarantee that the metal surface is thoroughly cleaned, dried, and appropriately prepared before the application of the waterproofing membrane. This preparation ensures optimal adhesion and effectiveness. For specific instructions on using a waterproofing membrane on metal block surfaces, it is highly recommended to consult a professional or refer to the manufacturer's guidelines.

- Q: Can a waterproofing membrane be used in swimming pools?

- Indeed, the utilization of a waterproofing membrane in swimming pools is widespread. To avert water leakage, it is a customary practice to incorporate waterproofing membranes during the construction or refurbishment of swimming pools. These membranes possess an exclusive design that enables them to function as a barrier against water infiltration, guaranteeing the pool's impermeability and leak-free condition. Typically, these membranes are crafted from robust materials like PVC, EPDM, or polyurethane, which exhibit resistance to water, chemicals, and UV rays. Furthermore, their flexibility allows them to effortlessly conform to the pool's shape and contours, providing a seamless and enduring waterproofing solution.

- Q: Can a waterproofing membrane be used in areas with heavy foot traffic or vehicle loadings?

- In high-traffic or heavy loading areas, it is possible to utilize a waterproofing membrane. Nevertheless, it is crucial to select a membrane specifically designed for such purposes in order to guarantee durability and longevity. These specialized membranes are typically thicker and more resistant to wear and tear. Furthermore, it is important to consider the type of traffic or loading that the area will endure. For instance, areas with vehicular traffic may necessitate a membrane with higher compressive strength to endure the weight of vehicles. In conclusion, the selection of the appropriate type of membrane that satisfies the specific demands of the application is of utmost importance when using waterproofing membranes in high-traffic or heavy loading areas.

- Q: Can a waterproofing membrane be used for plant rooms and mechanical equipment areas?

- Plant rooms and mechanical equipment areas can benefit from the use of a waterproofing membrane. It is necessary to waterproof these areas in order to safeguard the equipment and surrounding structures against water damage. A waterproofing membrane serves as a commonly implemented solution for this purpose. By forming a barrier, it effectively prevents water infiltration into the plant rooms and mechanical equipment areas, thereby ensuring the equipment remains dry and protected. Moreover, this membrane aids in averting moisture-related problems like the growth of mold and mildew, which can be detrimental to both the equipment's functionality and the overall operation of the plant room. Ultimately, incorporating a waterproofing membrane in plant rooms and mechanical equipment areas proves to be a dependable and efficacious approach for maintaining the longevity and performance of the equipment and structures.

- Q: Does a waterproofing membrane require any curing time?

- Indeed, a curing time is typically necessary for a waterproofing membrane to fully bond and establish a robust, impermeable barrier. The duration of this curing period can differ based on the type of membrane employed and the instructions provided by the manufacturer. While the membrane is undergoing the curing process, precautions should be taken to shield it from foot traffic, water exposure, and any other potential sources of harm. Adhering to the recommended curing time is crucial in guaranteeing the membrane's effectiveness and durability.

- Q: Does a waterproofing membrane require a protective layer?

- Yes, a waterproofing membrane typically requires a protective layer. The protective layer helps to shield the membrane from various external factors, such as UV rays, weather conditions, mechanical damage, and chemical exposure, thereby enhancing its durability and longevity.

- Q: Can a waterproofing membrane be used for planter boxes and green roofs?

- Yes, a waterproofing membrane can be used for planter boxes and green roofs. The membrane prevents water leakage and provides a protective barrier for the underlying structure, ensuring that the planter boxes and green roofs remain waterproof and durable.

- Q: Are waterproofing membranes resistant to high temperatures?

- The resistance of waterproofing membranes to high temperatures may vary depending on the specific material utilized. Certain waterproofing membranes are specifically engineered to endure high temperatures while retaining their effectiveness and integrity. These membranes often comprise materials like modified bitumen or synthetic rubber, which possess properties that enable them to withstand elevated temperatures. Nevertheless, it should be noted that not all waterproofing membranes possess resistance to high temperatures. Some membranes constructed from PVC or other thermoplastic materials may have limitations when exposed to extreme heat. Therefore, it is imperative to refer to the manufacturer's specifications and guidelines to ensure that the selected waterproofing membrane is appropriate for the intended application and can endure the expected temperature conditions.

Send your message to us

EPDM Rubber Waterproofing Membrane for Roof Protection

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5000 m²

- Supply Capability:

- 100000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords