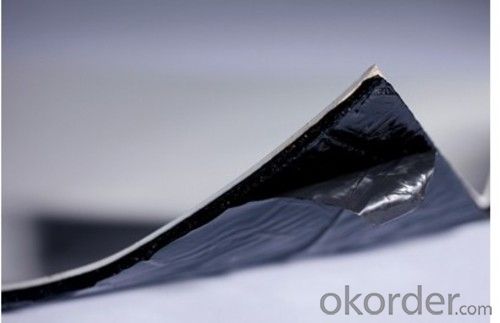

EPDM Waterproofing Rubber Membrane Used in Roofing

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5000 m²

- Supply Capability:

- 100000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Products Description:

EPDM waterproofing membrane is the modified materials. They are based upon EPDM rubber with modifier, softener and accelerant assistants added to provide flexibility and stability . Through the precise ingredients, mixing, extrusion, rolling, curing processes to made of modified EPDM Waterproofing material with high strength and high flexibility.

Product Specification:

Tensile Strength N/CM | Normal temperature: 60 ; 60°C: 30 |

Breaking Elongation % | Normal temperature: 400 ; -20°C: 10 |

Tear Resistance N | 20 |

Impermeability, 30 min no leakage | 0.3Mpa |

Low Temperature Bending °C | -20 |

Heating Shrinking mm | Extension: 2 Shrink: 4 |

Heat Resistance (80°C×168h) | Tensile Strength % : 80 ; Keeping rate of adhesive breaking:70 |

Alkali resistance (10% ca (oh)2 solution,normal temperature ×168h)) | Tensile Strength % : 80 ; Keeping rate of adhesive breaking:80 |

Synthetic aging | Tensile Strength % : 80 ; Keeping rate of adhesive breaking:80 |

Characteristic:

1.Excellent anti aging performance ,service life up to 50 years.

2.High extension rate,high tensile strength ,small size changes at heat treatment.

3.Good plant roots penetrability resistance and can be made waterproofing layer of planting roof.

4.Special modified molecular structure ,effectively resolving the current domestic and foreign glue joint problem.

5.Good low temperature flexibility ,and good performance of adapting to ambient temperature changes.

6.Convenient application ,solid joint ,no environment pollution.

7.Chemical corrosion resistance ,can be used for special occasions.

8.Good anti-perforated.

Applicable scope:

1.0mm 1.2mm 1.5mm 1.8mm 2.0mm EPDM waterproof membrane is widely used in roofs, basement, toilet, swimming pool, and all kinds of industry and civil building waterproofing, reservoir, bridge, underground, tunnel and dam waterproofing, especially to the keystone waterproofing projects which is durability, high corrosion resistance and easy deformation.

FAQ of Waterproofing Membrane

a.Can we get some samples before place order?

Answer: We can send the free samples to you by freight collect.

b.How many years can your PVC membrane guarantee?

Answer: We will guarantee the quality for 5 years at least.

c.Which countries you ever export the product?

Answer: We export the PVC membrane to South Africa, Middle east and even European countries.

- Q: Why the roof of the waterproof membrane and insulation rock wool board to do between the isolation layer?

- 2, the insulation layer can be done on the waterproof above, according to the nature of insulation materials, insulation layer and waterproof layer can be set between the isolation layer or not set. If the waterproof layer on the laying of polystyrene foam board, do not need to do isolation layer; if the block of inorganic insulation materials, such as foam glass, waterproof layer should be set on the cement mortar protective layer; if the waterproof membrane to do Foam concrete or polyurethane block insulation, you can dry in the coil a linoleum for the protection of the isolation layer.

- Q: Are waterproofing membranes suitable for crawl spaces?

- Yes, waterproofing membranes are suitable for crawl spaces as they provide a protective barrier against moisture and water intrusion, preventing issues such as mold growth, structural damage, and musty odors.

- Q: Can a waterproofing membrane be used for a shopping mall underground parking?

- In a shopping mall underground parking, it is possible to use a waterproofing membrane. Due to their below-ground location, underground parking structures are at a high risk of water infiltration. To prevent this, a waterproofing membrane is typically installed during the construction process. This membrane acts as a barrier, stopping water from seeping into the parking structure and causing damage. It is designed to withstand the pressure from the surrounding soil and any potential hydrostatic forces. Moreover, a waterproofing membrane can also help reduce the risk of moisture-related issues like mold or mildew, which can compromise the safety and integrity of the parking structure. Therefore, incorporating a waterproofing membrane is a widely used and effective solution to ensure the long-term durability and functionality of underground parking facilities in shopping malls.

- Q: Can a waterproofing membrane be used for vehicular traffic areas?

- Yes, a waterproofing membrane can be used for vehicular traffic areas. Waterproofing membranes are designed to protect surfaces from water damage by creating a barrier that prevents water from seeping through. In vehicular traffic areas, such as parking decks or driveways, it is important to protect the underlying structure from water infiltration, which can cause corrosion, deterioration, and expensive repairs. By using a waterproofing membrane specifically designed for vehicular traffic, the surface can be adequately protected from water damage, as well as other potential contaminants like oil and chemicals. These membranes are typically more durable and able to withstand the weight and impact of vehicles, ensuring long-lasting protection. Additionally, some waterproofing membranes offer slip-resistant properties, making them suitable for use in areas where vehicles may need traction. However, it is crucial to consult with a professional to determine the appropriate waterproofing membrane and installation method for specific vehicular traffic areas based on factors such as traffic volume, load capacity, and climate conditions.

- Q: Can a waterproofing membrane be used on tunnels with architectural features?

- Yes, a waterproofing membrane can be used on tunnels with architectural features. The membrane can be applied to various surfaces, including those with architectural features, to provide effective waterproofing and prevent water infiltration. This ensures the protection of the tunnel structure and helps maintain its integrity.

- Q: Are waterproofing membranes resistant to hydraulic oils?

- Waterproofing membranes are typically not resistant to hydraulic oils. Hydraulic oils are designed to be highly lubricating and can often penetrate and degrade the integrity of waterproofing membranes. Therefore, it is important to ensure that if hydraulic oils are present in an area where waterproofing is required, additional protective measures, such as using chemical-resistant membranes or applying suitable coatings, are taken to prevent any potential damage to the waterproofing system. It is always recommended to consult with a professional waterproofing contractor or manufacturer for specific recommendations regarding the compatibility of waterproofing membranes with hydraulic oils in a particular application.

- Q: Can a waterproofing membrane be used for warehouses or storage facilities?

- Warehouses or storage facilities can utilize a waterproofing membrane. These membranes are specifically designed to safeguard structures against water damage by creating a barrier that prevents moisture infiltration. In warehouses and storage facilities, there are often large areas that are vulnerable to potential leaks or seepage, such as roofs, walls, and floors. By installing a waterproofing membrane, these structures can be effectively shielded from water intrusion, thereby preventing harm to stored goods and maintaining the facility's integrity. Waterproofing membranes come in various types, including bituminous, liquid-applied, or sheet membranes, providing flexibility in selecting the most appropriate option based on the specific requirements of the warehouse or storage facility. Furthermore, waterproofing membranes offer additional advantages such as thermal insulation and resistance to chemicals, further enhancing their value in ensuring the durability and functionality of warehouses or storage facilities.

- Q: Can a waterproofing membrane be used in conjunction with concrete repair or restoration?

- Yes, a waterproofing membrane can be used in conjunction with concrete repair or restoration. In fact, it is often recommended to use a waterproofing membrane as a protective layer over repaired or restored concrete surfaces. This is because concrete repair or restoration may involve the removal of damaged or deteriorated areas, which can compromise the waterproofing properties of the original concrete. By applying a waterproofing membrane, you can ensure that the repaired or restored concrete remains protected against water intrusion, which can lead to further damage and deterioration. Additionally, the waterproofing membrane can also help to enhance the overall durability and longevity of the concrete structure.

- Q: Can waterproofing membranes be used in wet areas like bathrooms?

- Yes, waterproofing membranes can indeed be used in wet areas like bathrooms. In fact, it is highly recommended to use waterproofing membranes in bathroom areas to prevent water damage and leakage. These membranes are specifically designed to create a barrier against moisture, ensuring that water does not seep through the walls, floors, or other surfaces of the bathroom. By applying a waterproofing membrane, you can effectively protect the underlying structure from water damage, mold growth, and other issues caused by prolonged exposure to moisture. This is especially important in wet areas like bathrooms where water is constantly present. Waterproofing membranes are available in various forms such as sheet membranes, liquid membranes, and even pre-formed shower trays. They can be applied to walls, floors, shower enclosures, and other surfaces to create a watertight seal. It is crucial to properly install and maintain the waterproofing membrane as per manufacturer guidelines to ensure its effectiveness and longevity. Therefore, if you are considering renovating or building a bathroom, using waterproofing membranes is highly recommended to ensure a durable and moisture-resistant space.

- Q: Does a waterproofing membrane require any specific surface preparation?

- Yes, a waterproofing membrane does require specific surface preparation before installation. The success and effectiveness of the membrane largely depend on the quality and condition of the surface it is applied to. Firstly, the surface needs to be clean and free from any dirt, debris, oil, grease, or loose particles. This can be achieved by thoroughly cleaning the surface using a pressure washer, scrub brush, or appropriate cleaning agents. Any existing coatings or sealants should also be removed to ensure proper adhesion of the membrane. Secondly, the surface should be smooth and even. Any uneven areas, cracks, or holes should be repaired and leveled before applying the membrane. This can be done by filling the cracks or holes with a suitable filler or patching compound and smoothing it out to create a uniform surface. Thirdly, the surface should be dry. Moisture can compromise the adhesion and effectiveness of the waterproofing membrane. Therefore, it is important to ensure that the surface is completely dry before starting the installation. This may require allowing the surface to air dry or using appropriate drying methods such as fans or dehumidifiers. In addition to these general surface preparations, specific types of waterproofing membranes may have additional requirements. For example, some membranes may require a primer to be applied on the surface before installation. It is essential to follow the manufacturer's instructions and recommendations for the specific membrane being used. Overall, proper surface preparation is crucial for the success of a waterproofing membrane installation. It ensures optimal adhesion, durability, and performance of the membrane, ultimately preventing water penetration and protecting the underlying structure.

Send your message to us

EPDM Waterproofing Rubber Membrane Used in Roofing

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5000 m²

- Supply Capability:

- 100000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords