Double Impeller Centrifugal Pump

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Double Impeller Centrifugal Pump

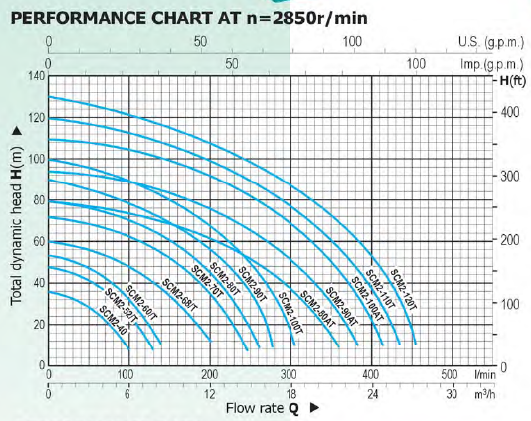

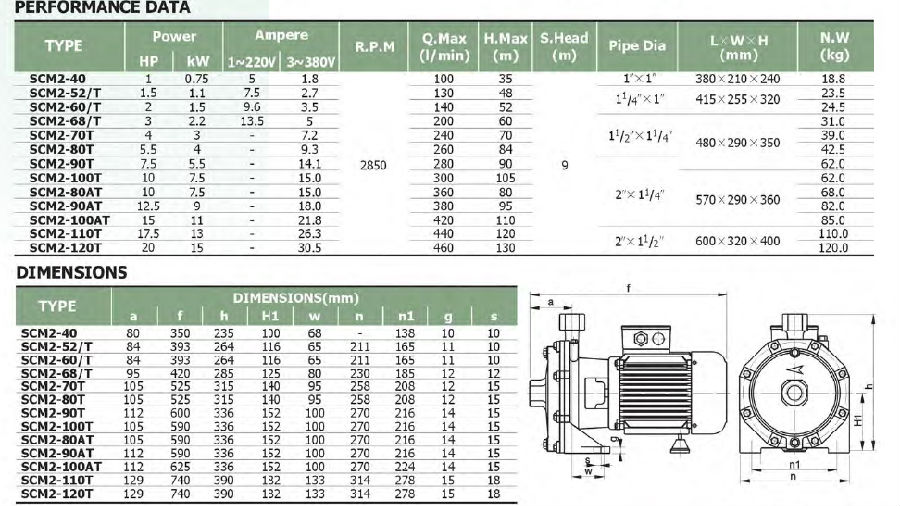

The SCM2 series are with two back to backimpellers, It is used for high head values, but if hard to reach with single impeller centrifugal pump.Suitable for civil and industrial uses to pump clean water and chemically non-aggresived liquid.Particularly be used for increasing for supply pressure, feeding boilers and loading extremely. These pump should be installed in a covered area, protected against the weather.

Pump body:Cast Iron

Impeller: Double brasss impeller

Motor:Closed, Externally ventilated

Insulation class:B(Class F if required)

Protection class: IP54/IP55

Duty:Continuously rated

Mechanical seal:Φ16, Φ18,Φ25 silicon carbide/graphite

Shaft:Stainless steel AISI 420

The normal power standard is 220v,50HZ,single phase

Three phase 220v/380v, 50HZ, 220V/460V, 60HZ

Single phase 230V, 240V, 127V,110V,115V/ 60HZ

Models are avaliable on request.

- Q: I have a 95 honda civic and I just got a new water pump. I need to know how to change it. I have an engine lift, I just want to know if the is an easier way?

- I had a 98 civic I did one on... The water pump runs off of the timing belt, so yea its a lot of work. You are going to have to remove an engine mount (pass side) support the engine with a jack and remove alot of the covers on the passenger side of the engine. I would suggest you get a repair manual at the auto parts store, probably the best $20 you'll spend (and more then I can cover here). Since you are in there, I would do the timing belt and the timing belt tensioner. Be careful not to turn the overhead camshaft when you have everything apart or you will have to set your cam timing again. Good luck, its probably a 7 out of 10.

- Q: Is pumping water, the new pump is also this problem, the pump is also working, that is, no water, at night I opened, in the installation of water, second days also make it to noon is not so good

- You pump 1. is fully automatic, 2. have small pressure tank 3., stop valve should be 1., tap water is interrupted, 2. water intake, water out of harmony

- Q: I was looking at a water pump and the specs said 110 Foot Max. Total Head and 20 Foot Max. Suction Lift. Can someone please explain this? Thanks.

- Head is the height over the pump location that a pump can push water, suction lift is the depth it can lift it from. Picture a 130' well with the pump 20' from the bottom and 110' from the top- in that case it will pump it... but without a volume factor (how much is going to flow) it's impossible to determine whether you'll get a trickle or a flow with those conditions.The store or manufacturer should be able to supply that info. Also the heights are relevant to sea level (or actual location above sea level) not necessarily the pipe length.

- Q: mercury 9.8hp.installed a new water pump impeller and still no water circulating through engine. no blockage anywhere. now what??? i`m stumped at this point.

- I have seen this many times on 9.87.5Merc'sThere is a plastic o-ring under the power head and it is probablly melted closed.There is a way to fix it without removing the powerhead.Remove the lower unit and pull out the water pickup tube.Then use a piece of brake line 5/16th sharpen on a 45 degree angle and push up the opening for the water pickup to open the passage.This will fix your water problem.

- Q: I currently have a gould 1/3 horse jet water pump and a rusted pressure tank that I would like to replace. There are two bathrooms, both with showers, 2 bathroom sinks and the kitchen sink, as well as the washer. What horse power should I have for 5 faucets and what size pressure tank would be sufficient? The shower in the upstairs bathroom hardly has pressure at all with the current pump and pressure tank. Any help would be greatly appreciated. Thank you in advance.

- your right on what it could, once i also have seen a vacuum hose and other hoses like evap hooked into coolant system boy some dude fried his face when he was stupid enough to pull the cap without backing on the evap one it exploded as he was working on it. You can rent a block tester from autozone the dye will turn green or yellow if the head is warped or the gasket is bad. Don't suck up coolant with it while the cap is off just the gasses it uses to determine. A bad water pump causes overheating overall usally or starts leaking, a bad thermostat getting stucked closed will cause overheating. Oh I have even seen cars where someone pulled the thermostat out to cover that up. Anyway, Stucked closed, Which would cause it to overheat as you drive or it is completly warmed up. You can feel both hoses to check it if it is opening and alowing coolant through the radiator.

- Q: can i drive my car ,with a blown water pump, 5 miles to a service center?

- Absolutely not. You'll most likely end up blowing the radiator. A great amount of pressure can/will be built up in the radiator and that's not good. I had the water pump go out in my Mazda MPV and didn't know it. I was going up the expressway and just so happened to notice that my temperature gauge was in the red and then I heard a pop and water and steam came shooting up from underneath the hood. You can usually only go about a 1/4 to 1/2 mile with a blown water pump. You'll have to get it towed.

- Q: Hello online mechanics! You guys have saved me a lot of money on my car, so now I have a new question! I have a 97 Ford Contour and lately since it's been cool in NJ, I've been hearing a tapping coming from the timing belt cover, but when the car warms up, there's no sound. I took the car to my mechanic and he says that I need to have the timing belt replaced, the pulleys adjusted, and the water pump changed. The price for doing the timing belt was $400 (including adjusting the pulleys) and $700 for the timing and the water pump. My question is ; do I need to do the water pump? He says that if you do the timing belt, that you should do the water pump too, but should I if there's nothing wrong with it ( as far as I know) and I'm not looking for the added expense? I thought if it ain't broke don't fix it still applies to things, or am I mistaken? Thanks guys gals! In these tough economic times, I'm not looking to spend any more than is necessary!

- make sure you have coolant in,or a couple month with out would burn the seals,sound like lifters as its goes away when hot (expand) try buying lukas oil stabilizer as it thicker and also lube better and run smother

- Q: Where is the water pump located in a 1995 Toyota tacoma pick up truck. Please be as specific as possible as the the location of the pump. Like what is it undwr or next to...etc

- If you have the v-6 then the water pump is driven by the timing belt and you have to remove the fan belts and the timing cover just to see it . The 4 cylinder the pump is driven by the fan belt that drives the alternator and the fan .

- Q: My old pump burned up so i recently replaced it (with a refurbished pump) I have new pipe to the pump, new tank. my pump is a 1/2 hp 230v pump, I also replaced the control box. With my pump plugged in and the water coming straight out of the pipe bypassing the tank when I turn the power on I will get water for a minute or so then I won't get water for a minute. This will keep happening. I have checked the switch and when I quit getting water there is still power going to the pump. any suggestions or ideas? bad wiring or bad pump?...I know that there is water in thew well, the pump is located at 100 ft of a 115 ft well and i can see the water level about 10 ft underground.

- Immediately I would suspect the referbished pump is not working properly. Unfortunately you will have to take it out and test it under the same circumstances you describe, but complete the system so the pump has some pressure to work against. Just running the pump with minimal pressure might not reveal the problem. Under working load the pump might be over heating (just enough to open a bad coil) and cause it to shut down till the coil cooled and made temporary reconnection. Good luck. )

- Q: the water pump from the factory has an extra hole coming out the side its the smaller one on the end of this pic.

- This is your recirculating pump. If it is a marine pump, it will have a brass backed seal and no heater hose outlet. (have seen them in the casting, but no hole there) The only difference is the casting, as long as it was ordered for the boat, you should be OK. For got to ask, do you have a cabin heater in the boat?

Send your message to us

Double Impeller Centrifugal Pump

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords