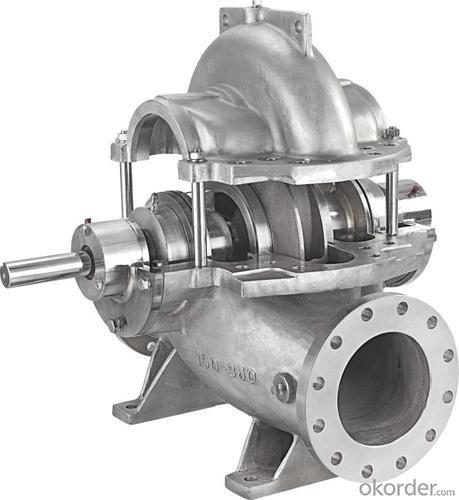

Stainless Steel Double Suction Centrifugal Pump

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 set

- Supply Capability:

- 200 set/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Advantage of Stainless Steel Double Suction Centrifugal Pump

Easy mantainance

Higher efficiency&saving energy

Low noise

Non-leakage

Stabel runing and longer operation life

Exellent Performance

Compact Structure

Both horizontal and vertical installation

Easy installation the pipeline,suction and discharge in one line

Applications of Stainless Steel Double Suction Centrifugal Pump

Type SBS Horizontal Axially Split Casing Double Suction Pump is wide apply in water works, irrigation, drainage pump station, power plant, municipal water supply system, firefighting, ship build. also can be apply in oil process industry, drainage in civil building, HVAC, metallurgy, chemical ,pharmacy,power plantetc for supply water or liquid property similar to water both in physics and chemical.

General description of Stainless Steel Double Suction Centrifugal Pump

State Patents (Patent Number: ZL01 2 39077.1) the advantage of vertical& horizontal installation construction to fill domestic blank. To match different installation requirement. strengthen casing design, high efficiency and save energy, compact design to ensure stable and reliable operation.

Model Explanation of Stainless Steel Double Suction Centrifugal Pump

SBS 125 500F/412

SBS SBS Horizontal Axially Split Casing Double Suction Pump

125 - Discharge Diameter (mm)

500 Impeller Nominal Diameter (mm)

F - Impeller hydraulic Code

412- Impeller Diameter Code

Technical data of Stainless Steel Double Suction Centrifugal Pump

Diameter of Discharge Flange: DN80 upto DN900

Capacity:Q:83 - 11600m3/h

Head:H:8 - 180m

Max Working Pressure:cast iron 1.6MPa, Ductile Iron and Cast Steel 2.5MPa.

Max Operating Temperature: 120 degree

Rotation Direction : from the driven end, the pump rotating direction is CW, also CCW rotation direction is available if needed.

FAQ of Stainless Steel Double Suction Centrifugal Pump

1. Are your pumps protected against dry running?

No, unprotected centrifugal pumps are not generally designed for dry running. It is important to give us or your dealer as much information as possible about the system in which the pump is used. Inlet pressure, the type of liquid to be pumped, together with relative density, viscosity and temperature, for example, are required in order to allow CNBM to recommend the right pump with the right gaskets for a long operating lifetime.

2. How can I get trained on CNBM products?

Yes, we provide training courses in our factory (products, general and specific pump technology, hydraulics, and practical applications). Please consult your sales manager or get in touch with our headquarters for more information.

3. Are your pumps cheaper than those of your competitors?

CNBM aims to give its customers the highest standards of quality and service and delivery times, all at a reasonable price.

- Q: how to install a main pipe water pump to service the community?

- Installation of water pump is very easy, any certified plumber and electrician can install electric water pump. Your question maybe is, how to design water pump water system to service the community? To determine the correct rating of water pump to be used and to design a water system, here are the steps : 1) Determine the safe discharge yield of your well for your water source, by series of tests. This will enable you to know discharge rate of well and the draw back time of water after pumping. This data will be used for designing a pump (its discharge capacity). Note that pump discharge capacity should be lower than well safe yield capacity in order not to drain the well. 2) Determine the suction lift or height of water table in the well by measuring the height from water table up to the top of the well. This data will be used for pump design (its suction lift/height capacity). Pumps suction lift varies depends on its Horsepower capacity and the type of pump (submersibble or centrifugal). 3) Determine number of households in the community. This data will be used for the design of reservoir (tank) for your water system and the number of hours for the pump to operate to fill the tank. Note that the average usage of water is 120 liters per day per capita. So the more the number of population, the bigger the tank and the longer the pumping time in order to meet the per capita usage. 4) Determine the elevations from your water source towards the community to be served. Use survey instrument to determine the elevations. This data will be used to design a height of the tank and the sizes of service pipes towards the community. The higher the difference in elevation from your source towards community, the lower the height of the tank and the smaller the sizes of service pipes. Sizes of service pipes can be determined by hydraulic heads (heights). By following these steps, I gues you can now design and construct a water system.

- Q: First the shop put in a heater core, but it was still leaking and overheating. Next they put in a water pump. Went to get it and now it wines really loud and the engine use to purr like a kitten, couldn't even tell it was running, now the engine shakes the whole car and it died one the way home but started again. The shop said the cam positioning needs reset again and on the way back to the shop it died again. So from leaking anti-freeze to now it vibrates, dies and wines really loud ! Any ideas what they did wrong ?

- Yea, this engine has the water pump that is driven off of the timing Chain, before removing the pump you have to install a holding tool to keep the timing gears synchronized, If the pump is removed first without installing the tool, the camshaft timing will be out of sync. and that's what probably happened. NOTE: This sounds like an unqualified shop to work on vehicles, if they can't trace a coolant leak! The first thing that should have been done is a CO2 test on the cooling system to see if the vehicle has any hidden head gasket issues. (Good luck)

- Q: I just put a thermostat in my 92 chevy but the gauge still shows close to hot but go down to normal pretty fast and occasionally i her a loud sound coming from the area where the belt is but i can't pinpoint it. I replaced the pump about three years ago, could that be it again so soon?

- Take it to the local machanic shop

- Q: It is a 110 shallow well pump for my water source to the house.

- If you mean your pump turns on and off rapidly (really short cycles) you have a waterlogged pressure tank. The pressure tank for your system has an air space inside that is separated from the water by a neoprene bladder or diaphragm. The air provides a cushion for the pump and system since air is compressible and water isn't. Sometimes the diaphragm will develop a small hole and water will enter the air space. You may be able bleed the water out and recharge the air or in some cases the diaphragm will have to replaced.

- Q: I currently have a gould 1/3 horse jet water pump and a rusted pressure tank that I would like to replace. There are two bathrooms, both with showers, 2 bathroom sinks and the kitchen sink, as well as the washer. What horse power should I have for 5 faucets and what size pressure tank would be sufficient? The shower in the upstairs bathroom hardly has pressure at all with the current pump and pressure tank. Any help would be greatly appreciated. Thank you in advance.

- your right on what it could, once i also have seen a vacuum hose and other hoses like evap hooked into coolant system boy some dude fried his face when he was stupid enough to pull the cap without backing on the evap one it exploded as he was working on it. You can rent a block tester from autozone the dye will turn green or yellow if the head is warped or the gasket is bad. Don't suck up coolant with it while the cap is off just the gasses it uses to determine. A bad water pump causes overheating overall usally or starts leaking, a bad thermostat getting stucked closed will cause overheating. Oh I have even seen cars where someone pulled the thermostat out to cover that up. Anyway, Stucked closed, Which would cause it to overheat as you drive or it is completly warmed up. You can feel both hoses to check it if it is opening and alowing coolant through the radiator.

- Q: What are the new regulations in the design of main and auxiliary water bin and water pump room in coal mine?

- The main water bin must have a main bin and an auxiliary warehouse. When a sump is cleaned, another water tank can be used normally.When the normal water inflow is below 1000m3/h, the effective capacity of the main water tank should be able to accommodate the normal discharge of 8h.The effective capacity of the main water bin can be calculated by pressing type in the mine where the normal water inflow is greater than 1000m3/h:V = 2 (Q+3000)Effective capacity of V-- main water bin in type m3;Q-- mine hourly normal water inflow, m3.However, the total effective capacity of the main water storage tanks shall not be less than the normal water inflow of 4h.The effective capacity of the water tank in the mining area shall be able to accommodate the normal water inflow in the 4H mining area.There is a big difference between the maximum water inflow and the normal water inflow in the mine. The drainage capacity and the water storage capacity should be specially designed.The water inlet chamber should be set up. A sedimentation tank shall be provided for the filling of water sand, hydraulic coal mining and other gushing water with a large amount of impurities. The water storage capacity of short positions must often remain above 50% of total capacity.

- Q: There is a loud squeecking noise coming from the water pump and the serpentime belt isnt loose!I dont know how long it would take a mechanic to do the job?

- type into search box how to replace water pump how to replace water pump s-10 how to replace water pump chevy about two to four hours maybe depending on mechanic and how busy the shop is and before you go and start replacing water pump if its not leaking its not bad yet and most likely will be a bad pulley or belt tension-er which go bad before water pump most of time you can spray water or wd40 on pulley to check if motor not running hot and you dont see any coolant coming from water pump most likey not bad belt tension-er pulley cost about 30 bucks anyone can replace in about 30 minutes

- Q: I am trying to evaluate my well water pump and water system to see if the pump is cycling on/off too frequently. What is the optimal quot;ontime? What is the optimal quot;offtime? I have heard the term quot;short cyclingquot;, but no times were attached. I have heard that too frequent cycling can cause a problem, but, again, no times were attached. How can one tell when the system is working within the optimal/normal range, so that no harm is being caused to the system? Thanks.

- There is no optimum time. This is dependent on several factors. Assuming you are pumping into a small tank which is pressurized by the inflow of water from the pump (and the pressure also controls the pump) these reasons can be excessive use of water, the air space at the top of your tank has been absorbed into the water over a period of time and the volume of compressed air too small causing the pressure to drop too fast, or you could have leak in your water piping. If there is not enough air space in your tank, the pump will cycle extremely fast. If you don't have a tank, then the above information is incorrect. Good luck.

- Q: I have a water pump that works with 12V and 2 amps.I was thinking to get a potentiometer to be able to slow down the speed.Is this the best way to do it? What wattage should it have, so it doesn't burn out, and what should be the maximum resistance, to be able to stop the pump completely?And OKorder or product link would be great!Thanks!

- A potentiometer will work, and this could be wired in series with the pump as long as its minimum resistance was zero ohms. You can also use an adjustable voltage regulator which would likely be more energy efficient but a more complex device. A potentiometer or regulator would need to have a minimal rating of 12V * 2A = 24 watts. A potentiometer, that is made for 12 volt applications, should be available at a local auto parts store. It has a simple, ceramic insulated, wire-wound resistor, and should have a 5 to 10 amp rating Sources below are to more sophisticated controllers than a simple potentiometer.

- Q: Domestic pump does not use water, or turn, I do not know why?

- Your home should be the pipeline booster pump, a pressure switch outlet of the pump, if no water will switch off, open the water tap water pump will work ~ ~ should be the pressure spring on this switch is broken, with 4 years of spring rust, not the original so good toughness. Another reason is that when the water pressure is not enough, the pump will work, but this can be ruled out.

Send your message to us

Stainless Steel Double Suction Centrifugal Pump

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 set

- Supply Capability:

- 200 set/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords