DIN Standard Horizontal End Suction Water Pump for Water Circulation

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 set

- Supply Capability:

- 10000 set/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

End Suction Centrifugal Pump

1.Structure of End Suction Centrifugal Pump Description

End Suction Centrifugal Pump complies fully to the European Standard BS EN733 / DIN24255 of performance and dimensions. They are used for pumping clean water or liquids similar to water, achieving wide application on plants, mines, city water supplies, air-conditioning coolers, firefighting system and irrigation. Pumps of the same model have different performance levels basing on different diameter after impeller trimming. Overall the whole series, there are only four sizes of shaft and five of bearing housing. As long as their bearing housings are of the same size, different pumps can interchange chief parts such as shaft, shaft sleeve, shaft seal, impeller nut, etc.

End Suction Centrifugal Pump is also very easy to be installed and maintained. Back pull-out design, driven through flexible coupling, so that pump casing and motor can remain in position while other spare parts are removed.

2.Main Features of the End Suction Water Pump

• very easy to be installed and maintained

•Back pull-out design

•Driven through flexible coupling

•Customized design is available, OEM and ODM are welcomed.

•Horizontally and vertically installation as different pipeline system

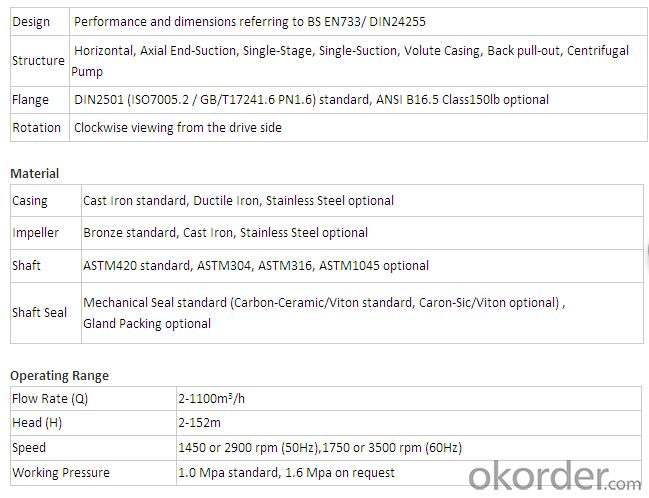

3.End Suction Water Pump Specification

4.Picture of End Suction Pump

5.FAQ

① What is your product range?

Centrifugal pump, slurry pump, gravel pump, clean water pump, sewage pump, chemical pump, single stage

pump, double suction pump, industry pump, oil pump, paper pulp pump, mud pump, self-priming pump, pipe

water pump, boiler water pump, etc.

② Are you a manufacturer?

Yes, we have been in manufacturing and marketing industry centrifugal pump over 20 years.

③ What information should I let you know if I want to get a quotation?

Pump capacity, pump head, medium, medium temperature, pump material, quantity, if possible, please also provide the pump model you are using now, price will be calculated as per the pump model, if not, we will recommend relevant product for reference.

- Q: Hello! Can someone please tell me where the water pump is located on this vehicle? Or where I might find the answer to this question?Thanks!

- water pump is located on pass side of the motor right where serpentine belt is

- Q: How to install circulating water pump for cooling tower?

- Water pump, cold water pump and hot water pump, the specific installation depends on the location of the cooling tower and the location of the heat exchanger, high cooling tower position, the need for hot water pump, heat exchanger position high.The cooling tower, cooling tower (Cooling tower), is using water as coolant, from a system to absorb heat emissions to the atmosphere, heat exchanged to produce steam, steam heat to volatile evaporation dissipation, convection and radiation heat transfer principle to disperse industrial waste heat or refrigeration and air conditioning to reduce evaporation cooling device therefore, in order to ensure the normal operation of the system, device as a barrel. The cooling tower can be divided into natural ventilation cooling tower and mechanical ventilation cooling tower according to its ventilation mode.

- Q: Could this be a result of a bad water pump.

- Possible head gasket or warped head. The water is getting out to the water jacket and into the top of the piston. Some water coming out of the exhuast is normal. It would not be a water pump.

- Q: we are trying to replace a water pump on our ford windstar mini van. my uncle cant figure it out and we can not get a manual until tomorrow. was wondering if anyone knew how. thanks

- water pump are kind of difficult to replace you have to remove several parts to get to it. specially if is your uncle first time. my recommendation is if you want to do it yourself to save money, have some one (family member)that did it before, just in case. go to source i will post instructions look at Table of Contents or go all the way on the bottom of the page good luck

- Q: I'm using an old Mitsubishi Lancer. Recently I changed my water pump it was leaking.To me it looked like a piece of metal, with a small fan thing (not motorized) How can it fail? There is no mechanics to it, just like a pipe with a fan (or turbine)I also messed with my radiator, I unhooked the main hose to clean out the coolant, since the plug was jammed. Could this have contributed to the failing of my water pump?

- if the plug was jammed then the most likely cause was some type of sealant someone put in the radiator to fix a leak......this is a prime example of why I say never to use the sealers in your engine....... what happened to your water pump is really rather simple......the waterpump (WP) is a simple device that spins and has bearings......the coolant you buy in the store has lubricants in it to keep the waterpump luricated.....the sealer that was put into the cooling system sealed of the passages the coolant uses to lubricate the WP bearings......this created too much friction and wore your bearing out causing the pump to fail!!!!!!......you need to flush the cooling system thoroughly several times to get all the sealer out......even then it will take a little luck and lots of praying for the sealer not to plug your engine water jacket and cause overheating!!! good luck!!!

- Q: Our watrer pump on our well will constantly prime itself when we use the water in our house.As you are running the tap the water will gain pressure on and off like someone is using another tap in the house. Any suggestions?THanks in advacne

- How old is the Pump ? Could the Impeller be worn out ? Is there a replaceable filter ? Could it possibly be stopped up ? Are there any leaks in the pipe leading from the well ? Is there a way that you could measure the current being drawn by the pump, with an Amp Meter, to determine if it's pulling more Current than it should be ? Until these questions are answered, it's probably just going to be a guessing game.

- Q: Bought a new water pump for my turtle tank can't get it to work

- hi, I advise you drain the pond/inventory tank and positioned a trough hull installation to allow you to hook up a valve for prompt draining. I used a a million one on my 3 hundred gallon inventory tank and it will drain in below 5 min. otherwise a submersible sump pump is the suited type to get they have a exhibit on the backside the place the %. up is to evade plugging you are able to could sparkling the prefilter exhibit periodically. You hook up a backyard hose and drop it in.

- Q: I have septic tanks. My toilet flushing water is filthy and the water pump runs for a long time and sounds strange. I have turned the pump off for now but know this is not an answer but i was worried it would burn out or something. Do i need a part for the pressure pump? Please help any plumbers out there.

- Oh, groan ...up at 5:30 in the morning with water problems! Well. I guess it makes life 'interesting! ...lol Your well is running dry. - It is what I suspect. - Had the same problem, long ago. First of all ...you don't have septic tank(s). - You have only (1) septic tank. You can't let your water pump run-on like that. - It will overheat and burn out. My water pump was $700.00 dollars! I'm suspecting your water recovery rate in your well is very slow. - Time of year 'possibly'. - Or your well was just not dug deep enough in the first place, to have much reserve water capacity. What looks like dirty water, is probably really actually only sand and silt, that your water pump is sucking up, when your well runs close to dry. There's a free remedy. Squeeze a clamp onto the rubber washing machine water hose. - To restrict the rapid flow of water into your washing machine. If you're watering your garden ...don't water for too long. - Or the well will run dry. I put a water timer on my garden hose, so it only watered my garden for 5 minutes, every half hour. Leaving it that way 'all night' and you'll wake up to a well watered garden in the morning! I'm sure this is your problem, - low water recovery rate in your well - because that would account for the water turning silty. Be ingenuitive ...and it won't cost a penny, or inconvenience. Trini ps. The water that is pumped into your toilet, is well water. The septic tank is where the well water flushes the poo poo to. pps. You're right in turning the water pump off while you wait for the well water to recover!

- Q: Iv got a 2002 Chrysler Sebring with a 2.7 in it and recently it started leaking coolant, its been determined that i need a new water pump. Iv gotten quotes from various places and various prices but there all telling me i need to replace different things. One guy said i need a timing kit, the other guy said i dont need a timing kit but need valave covers and a couple other things, another said i dont need anything but the pump itself. Im lost and the leaks getting worse and i need to make a decision but dont know what to do. Some insight from you helpful people would be great!

- In Your Vehicle The Water Pump Is Run by the Timing Belt. If It Has been Leaking It Will have Contaminated the Timing Belt, Which Has to be Removed Anyway To Replace the Water Pump. So Replace Water Pump, Timing Belt and Tensioner And Coolant. It is Also Recommended To Replace the Thermostat At This Time.

- Q: If you use a water pump to move water through a circular trench, essentially making a little river, and then place some kind of turbine or water wheel or something to generate electricity from the moving water, couldn't you use the electricity generated by the turbine to power the pump, thus requiring no outside power?

- No, every energy conversion process is less than 100% efficient. In other words, when the pump and motor raise the water energy is lost. Now when the water flows more energy is lost. When the water turn the turbine more energy is lost. Finally, when the turbine drives the motor to produce electricity more energy is lost.

Send your message to us

DIN Standard Horizontal End Suction Water Pump for Water Circulation

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 set

- Supply Capability:

- 10000 set/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords