DIN Standard End Suction Water Pump for Water Circulation

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 set

- Supply Capability:

- 10000 set/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

End Suction Centrifugal Pump

1.Structure of End Suction Centrifugal Pump Description

End Suction Centrifugal Pump complies fully to the European Standard BS EN733 / DIN24255 of performance and dimensions. They are used for pumping clean water or liquids similar to water, achieving wide application on plants, mines, city water supplies, air-conditioning coolers, firefighting system and irrigation. Pumps of the same model have different performance levels basing on different diameter after impeller trimming. Overall the whole series, there are only four sizes of shaft and five of bearing housing. As long as their bearing housings are of the same size, different pumps can interchange chief parts such as shaft, shaft sleeve, shaft seal, impeller nut, etc.

End Suction Centrifugal Pump is also very easy to be installed and maintained. Back pull-out design, driven through flexible coupling, so that pump casing and motor can remain in position while other spare parts are removed.

2.Main Features of the End Suction Water Pump

• very easy to be installed and maintained

•Back pull-out design

•Driven through flexible coupling

•Customized design is available, OEM and ODM are welcomed.

•Horizontally and vertically installation as different pipeline system

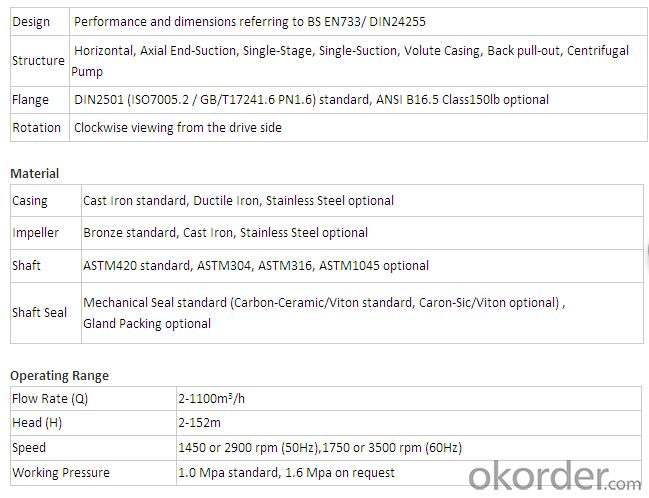

3.End Suction Water Pump Specification

4.Picture of End Suction Pump

5.FAQ

① What is your product range?

Centrifugal pump, slurry pump, gravel pump, clean water pump, sewage pump, chemical pump, single stage

pump, double suction pump, industry pump, oil pump, paper pulp pump, mud pump, self-priming pump, pipe

water pump, boiler water pump, etc.

② Are you a manufacturer?

Yes, we have been in manufacturing and marketing industry centrifugal pump over 20 years.

③ What information should I let you know if I want to get a quotation?

Pump capacity, pump head, medium, medium temperature, pump material, quantity, if possible, please also provide the pump model you are using now, price will be calculated as per the pump model, if not, we will recommend relevant product for reference.

- Q: Building installation problems, beginners, many problems need to be solved, thank you!

- Because each manufacturer's label is different, the country although some specifications, but not enforced, so purely from the literal meaning is difficult to explainWe will try to solve the following problems:WQ-- sewage submersible pump80-- outlet diameter of water pump40 - M /h fand flow15 lift M1600 speed, r/min4Kw powerAs for J, Y is rated as sealed form and waterproof gradeI don't know whether it is correct or not

- Q: Water pump is STILL constantly running! Since this past thursday, we did:new check valvenew pressure controlnew foot valve (well)well is not dryprime, air pressure are finewe have above ground pump in the basement. we called a plumber and he could do nothing! we have water and pump/tank and everything seem working fine.But the pump is on and off every 30 seconds - 1 minute. It is so annoying and out of ideas what could be wrong.My husband think it could be the tank and suggested that we replace it. But the plumber didn't say anything about the tank. And it is not too old.Do you think it is the tank and we need to replace it? If so, we will do it on this Sunday morning even though it might cost extra charge! please help!!!

- Reading through what you have replaced about the only thing it could be is you have a hole in the supply line somewhere. If the tank needed replacement, when there is no draw on the system, like when you get a drink of water, there will be no cycling of the pump. In other words if there is no spigot on then there must be a leak somewhere.

- Q: Today I was installing a new water pump on my 1999 grand Prix. When tightening the bolts one of them snapped off. Now the pump leaks from that broken bolt. I was wondering if I would be able to stop the leak using some sort of sealant or would I have to take the car in to get the bolt removed?

- Go the your local hardware store and ask them for a bolt extractor kit. You will need to drill into the center of the bolt about 1/2 inch and then change the bit to the extractor that's in the kit. Try to keep the drill level and back it out slowly. Don't forget to get a new bolt also.

- Q: The flow of the pump will be reduced, the speed will change, the power of the motor will change?

- Water pump flow rate, speed will not change, the power of the motor will change in general.Different types of pumps have different flow power curves. Only the most common centrifugal pump is used as an example to illustrate the relationship between the flow rate and other pump parameters. The typical centrifugal pump flow power curve is shown in the P-qv curve (red line) shown below.Turn left and turn right |According to the flow power curve, it can be seen that with the increase of the flow rate, the power increases linearly, and the power decreases linearly with the decrease of flow rate.In fact, the pump shaft power P= P gQH/ (1000 K), including H: head, unit m, Q: flow unit m3/s, ETA: for the efficiency of the pump, general 0.7-0.85, P: shaft power, unit kW, K: matching coefficient, small power is 1.25, P: work is like a water medium density.Therefore, for a specified pump, the power is proportional to the flow theoretically. In fact, as the flow rate changes, the efficiency of the pump changes, so it can only be close to the positive proportion.Running water pump speed generally depends only on the pump, power (motor, diesel, etc.) speed, the flow of water generally can not affect its speed. But in the design of pumps, the flow is related to the speed, and other design parameters remain unchanged, the pump speed is high, the pump flow.

- Q: What is the function of a submersible pump?

- Submersible pump motor and pump is directly connected with the water pump body into the water to work, it is suitable for the extraction of groundwater from wells, can also be used in rivers, reservoirs, canals and other water projects: mainly used for irrigation and plateau in the drinking water, but also for the city, factories, railways, mining and construction site the use of water supply and drainage.Characteristics of submersible pumps for well1 、 motor, water pump, submerged operation, safe and reliable.2, the well pipe and pump water pipe without special requirements (i.e.: steel tube wells, tube wells, Doi ash can be used).3, installation, use and maintenance of convenient, simple, small footprint, do not need to build pumping stations.The structure is simple, and the raw materials are saved.4, submersible pump conditions are appropriate, properly managed, and has a direct relationship with the service life.

- Q: I keep having to add water to. Doesn't do anything when it's sitting up. But after you drive it straight for about 25 minutes. Time to add some more water. I figure it's the water pump. It's not leaking anywhere so it has to be a failing water pump. Oil still looks good, no smoking. AC and heater blows fine. Just runs hot after a while. I need another opinion. Its the 4 cylinder also. And yes it does be steaming. Tired of having to add water everyday.

- Forget the check this and try that stuff. You need a RADIATOR SHOP the radiator is plugged and you can do nothing to clean it. Don't waste time on flushing as it is a waste. Water pumps have mechanical seals and require no lubrication and anti freeze contains no lubrication material. Plain water will not affect the pump. Never replace any part 'till you KNOW the problem

- Q: Why does the water pump leak?

- Two reasons.One is that the gap between the bearings becomes larger. Damage the water seal. One is the aging of water seal.

- Q: i'm changing the tyming belt the vehicle has done 120,000 km should i replace water pump as well

- Hi strange you say this it seems like when ever a timing belt is changed on a toyota the water pump is always an issue, i was warned that the same is true on my land criuser that the water pump may need to be replaced when the timing belt is changed.

- Q: my heater in my 94 ford ranger went out about a month ago today i flushed the heater core and it worked for a while and started going out again after i was driving for 15 to 20 mins. the hose going into the heater core was warm but coming out wasnt. could it have gotten clogged again or could it be something else.

- your right on the problem so to really figure it out take the hose off or lose enough to make a mess and see it flowing. Take it off at the water pump thats where it comes out at. the water pump pumps water into the radiator or up, not the other way around.

- Q: My water pump went out. I had a new water pump put on my accord a year and a month ago. Since then have driven 5-6,000 miles in a small city town. Does this makes sense. Could it be a cheaper water pump was put on my car and it went out. The person who worked on it is a mechanic who does a bunch of cars on the side. Last time he worked on my brakes, I had to bring it back because he put cheap ones on.Can I call this guy back? What could I say?

- Unfortunately most water pumps,even new ones, are warrantied for one year so while you may have to pay for another one I'd be sure whoever I paid for the labor was a different mechanic. Even new pumps can go bad prematurely but a reputable shop would probably make some allowances since its so close to the warranty limits. The other advice given about the coolant is spot on too. It should have been refreshed at the time the pump went in but just because it should have, doesn't mean it was.

Send your message to us

DIN Standard End Suction Water Pump for Water Circulation

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 set

- Supply Capability:

- 10000 set/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords